Piston pumps for oilfield water injection

An oilfield water injection and plunger pump technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc. Achieve the effect of reducing failure rate, improving service life and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

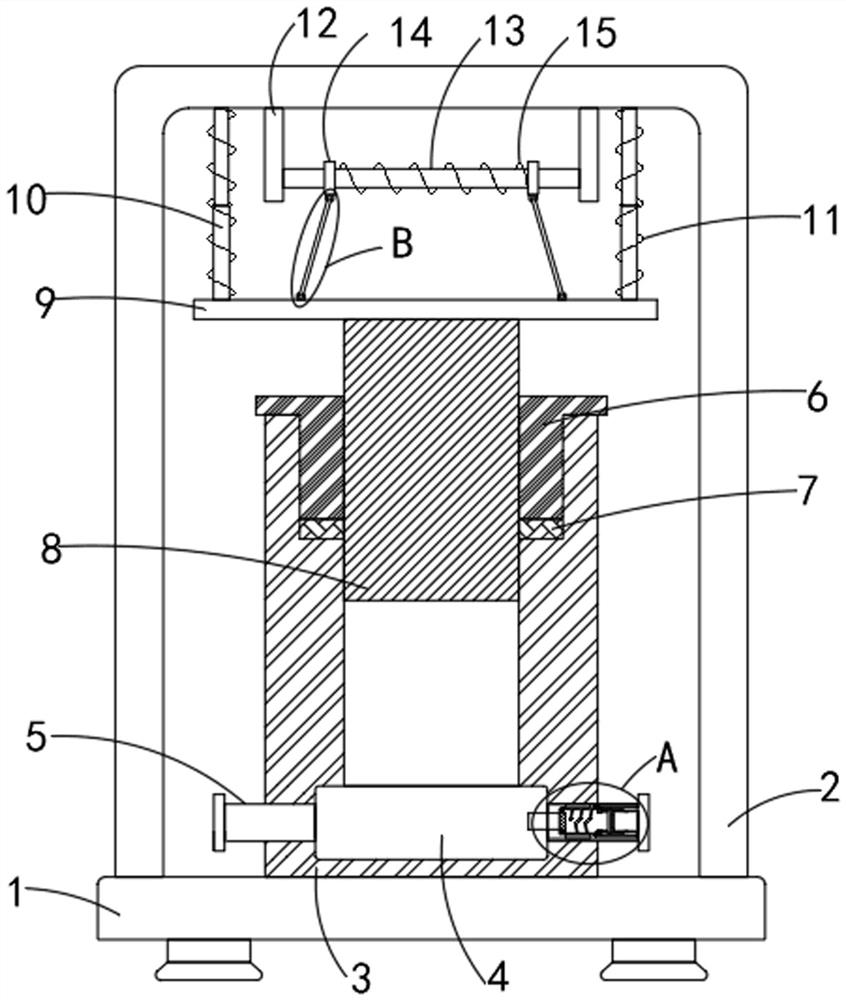

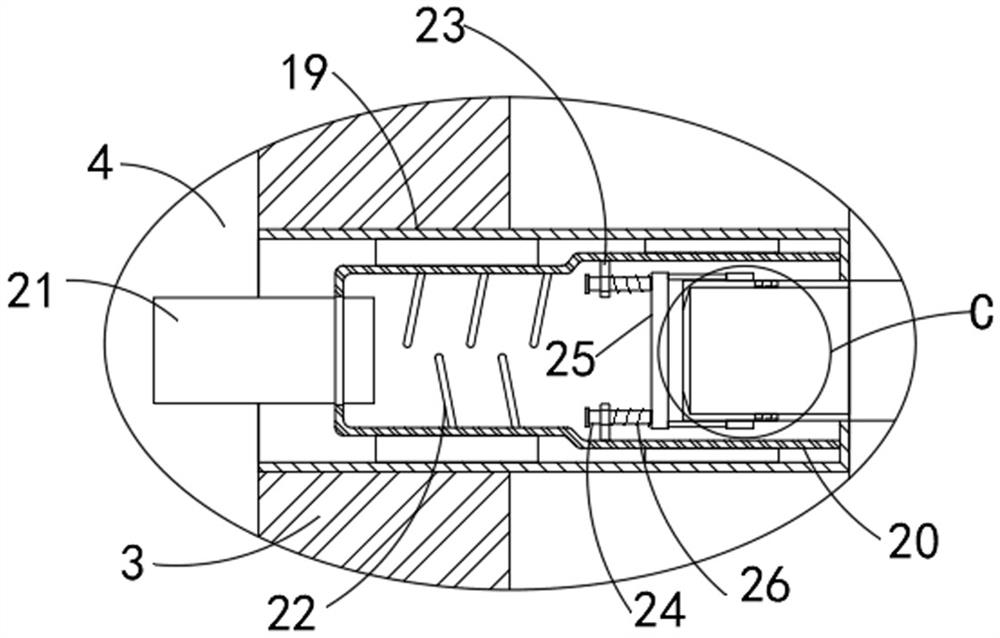

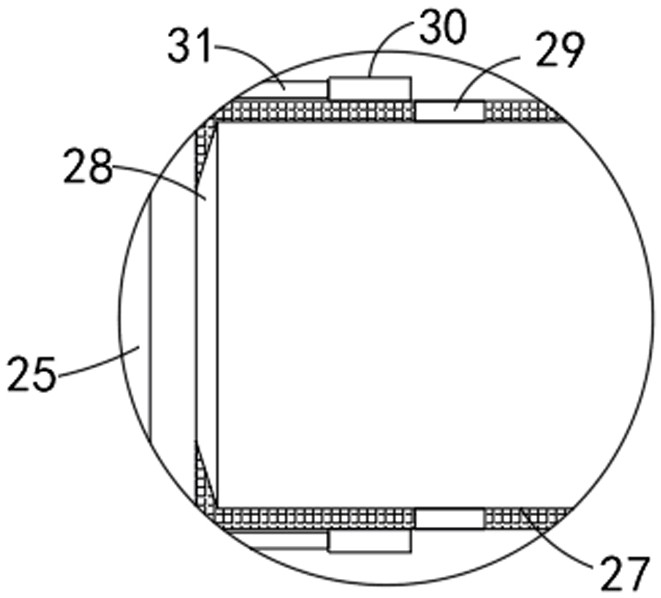

[0024] refer to Figure 1-5 , a plunger pump used in oil field water injection, including a base 1 and a support frame 2, the support frame 2 is fixed on the base 1, the support frame 2 is set in an inverted "U" shape with the opening facing downward, and the outer surface of the support frame 2 is plated A layer of anti-corrosion coating with uniform thickness is provided. The anti-corrosion coating improves the anti-corrosion ability of the support frame 2. The lower side wall of the base 1 is provided with multiple groups of evenly distributed supports, and the lower side wall of each support is fixed. There is a grid-patterned silicone pad, which increases the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com