High-efficiency low-noise axial flow fan

An axial flow fan, high-efficiency technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of large eddy current loss, large airflow resistance, unsmooth airflow, etc., to improve appearance, reduce noise, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

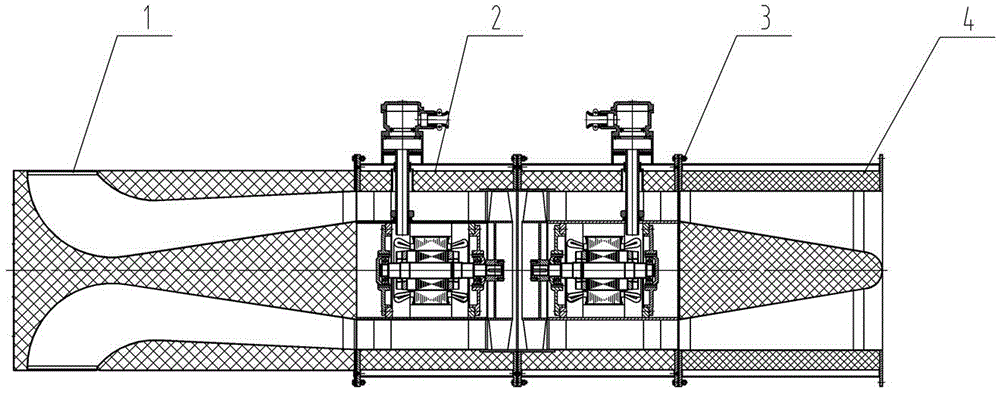

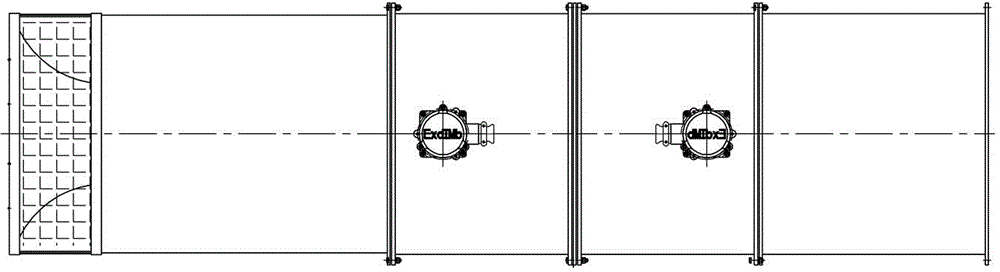

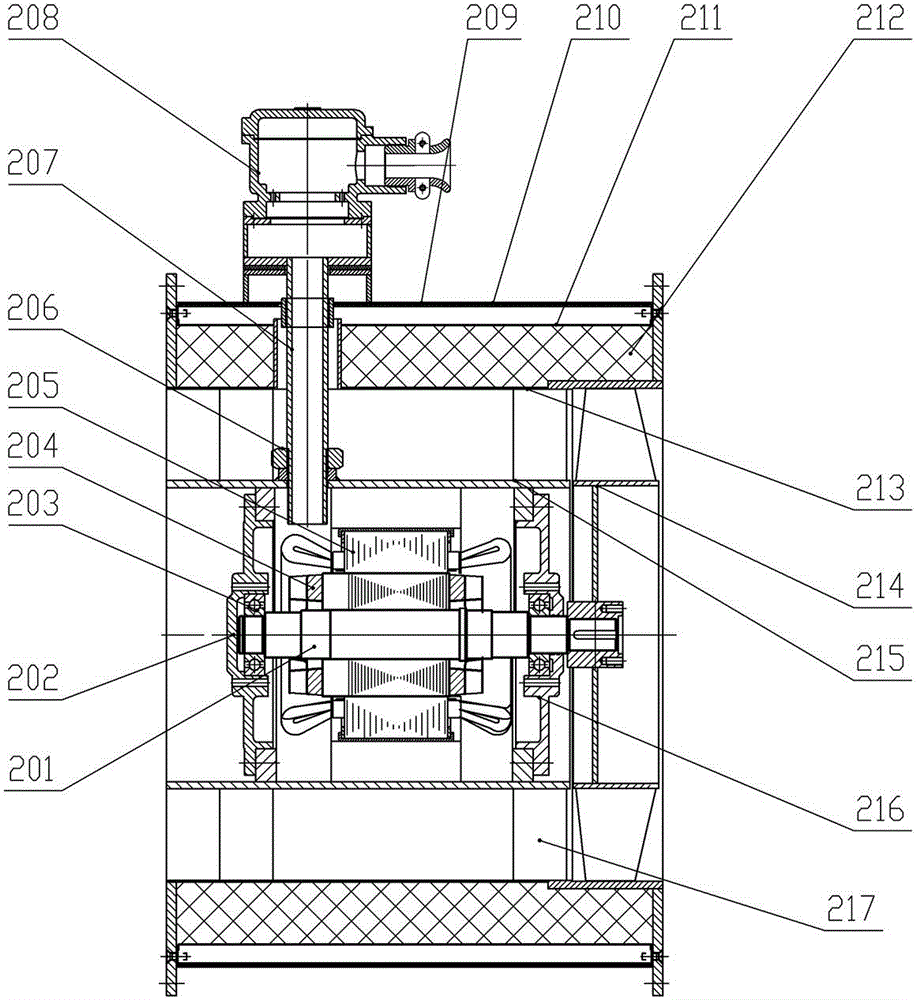

[0039] Example 1, such as figure 1, the present invention includes a main engine 2 and a radial annular air inlet and outlet muffler 1 and a muffler diffuser tube 4 respectively connected at both ends. The main engine 2 includes a shell 209 with a sound-absorbing structure, which forms an air passage with the motor shell 215 . The inner wall of the motor housing 215 is provided with ribs or sectors to support the stator 205. By adjusting the height of the built-in ribs or sectors to match the diameter of the stator, the outer surface of the motor housing 215 is ensured. The diameter is consistent with the diameter of the hub of the impeller 216 and the diameter of the inner cylinder of the front and rear mufflers. One end of the motor casing 215 is basically flush with the end of the main engine casing. After the other side is connected to the impeller, the width of the hub is also the same as the end of the main engine casing At the same time, arrange the flange and the end ...

Embodiment 2

[0045] Example 2, Figure 10 to Figure 13 , which embodies the different internal structures of the radial annular inlet (outlet) wind muffler. According to the principle of radial annular inlet (outlet) wind muffler, the inside of the flow channel is designed as more than one bend, and the noise goes outward along the flow channel. When propagating, there are multiple "barriers" to block, and the noise reduction effect is better; the radial annular inlet (outlet) can be set in the radial direction or axial direction, but the air inlet (outlet) channel has a tapered (expanded) area. The geometric shape is a structural feature that transitions from a radial ring to an axial direction. It is also possible to add a ring-shaped noise reduction structure on the outside of the radial ring-shaped inlet (outlet) to relatively close the flow channel, so that the airflow noise can be blocked by the ring-shaped noise reduction tube once more, and then enter (out) in the axial direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com