Stacked overflow type sewage treatment equipment

A kind of sewage treatment equipment, overflow technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sedimentation treatment, etc., can solve the problems of low purification efficiency, high operating cost, inconvenient installation, etc., to achieve Good purification effect, increase the total capacity of water flow, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

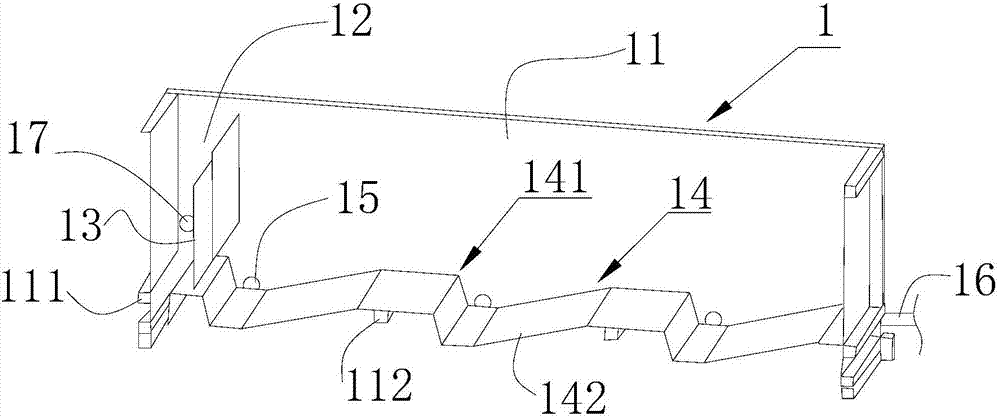

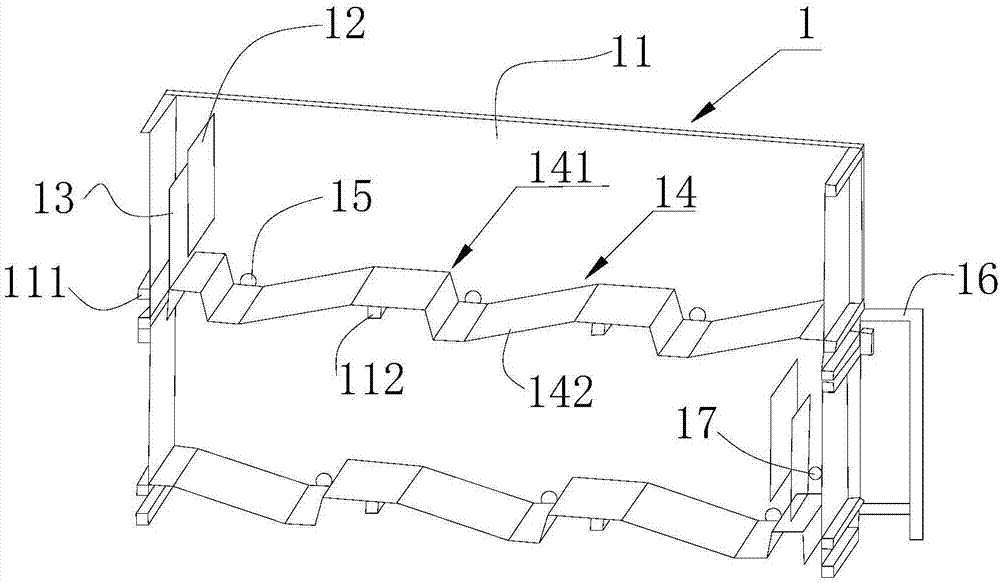

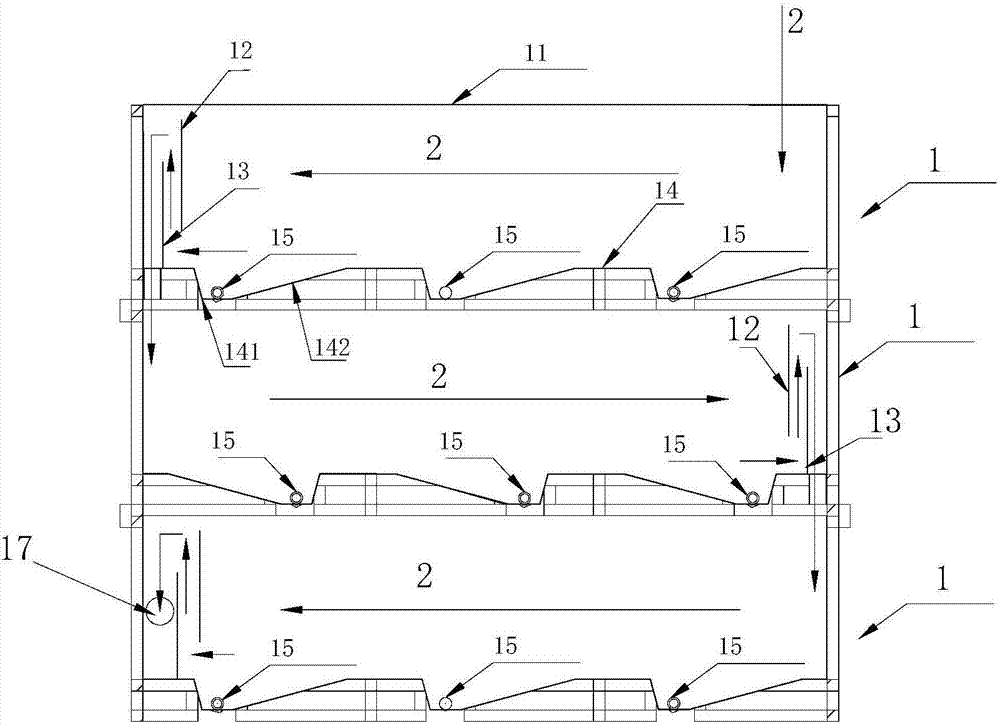

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

[0024] The present invention provides a new type of stacked overflow sewage treatment equipment with modular assembly and adjustable volume. The equipment is assembled from a plurality of stacked boxes 1. The stacked box 1 includes a box body 11 and a first baffle 12. , overflow plate 13, settling tank 14, sewage outlet 15, sewage pipe 16,

[0025] The box body 11 is realized by the prior art. A cavity is formed in the middle of the box body 11. The upper and lower ends of the outer walls on the left and right sides of the box body 11 are protrudingly provided with convex portions 111 respectively. ends flush.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com