Hydrocycloneseparation dryer for solid-liquid separation of water-bearing granular materials

A technology of cyclone separation and solid-liquid separation, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc. It can solve the problem of inability to remove water attached to the surface of particles, unable to meet actual production needs, and large water content of particles. and other problems, to achieve the effect of improving solid-liquid separation efficiency, reducing volume and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

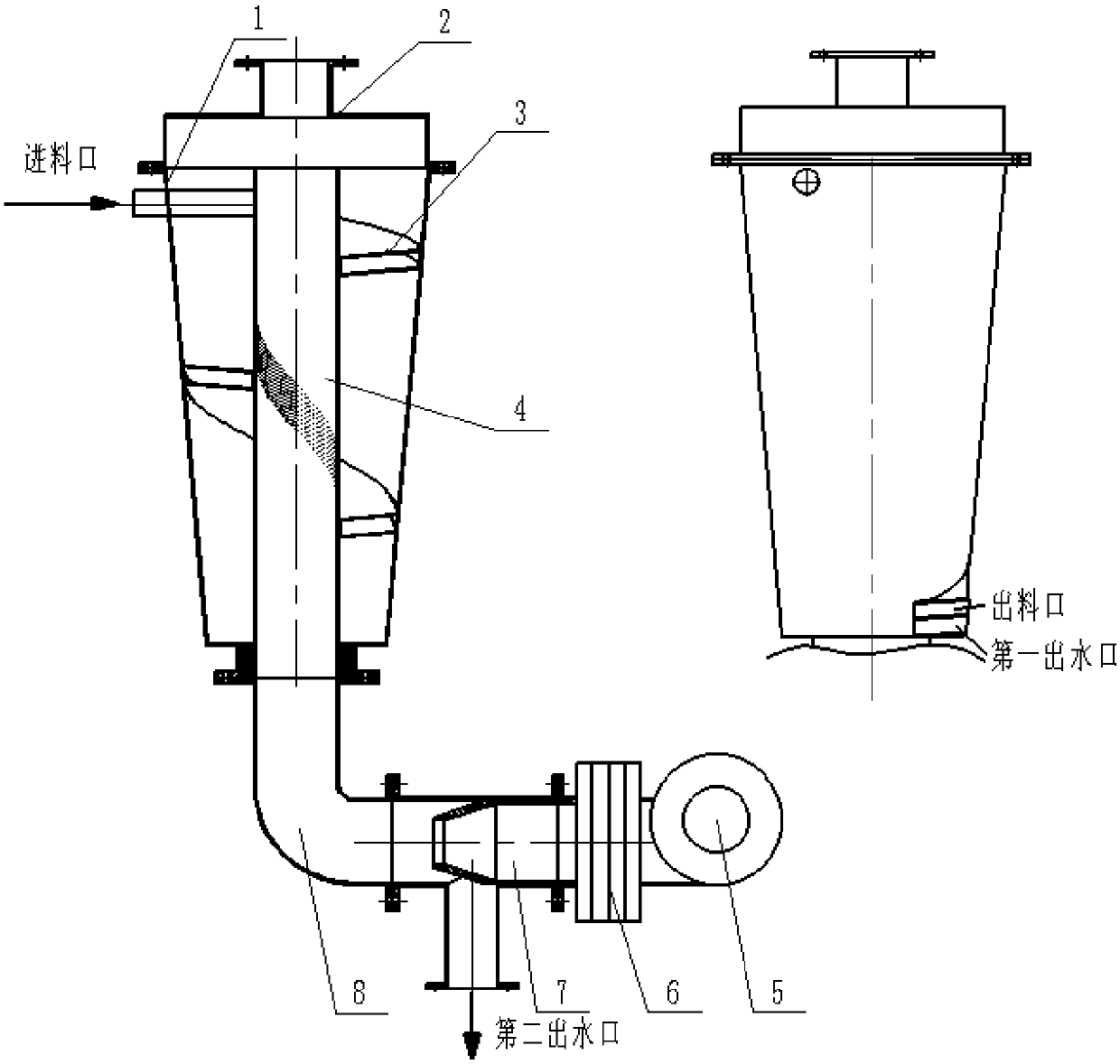

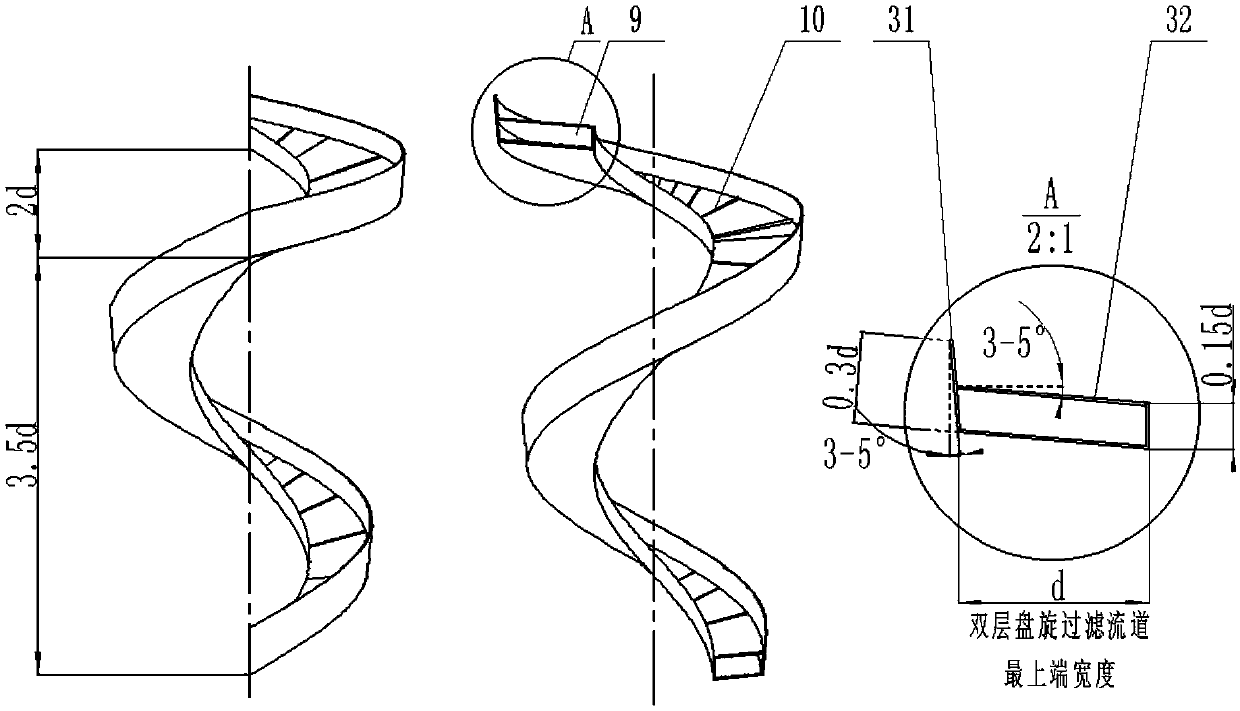

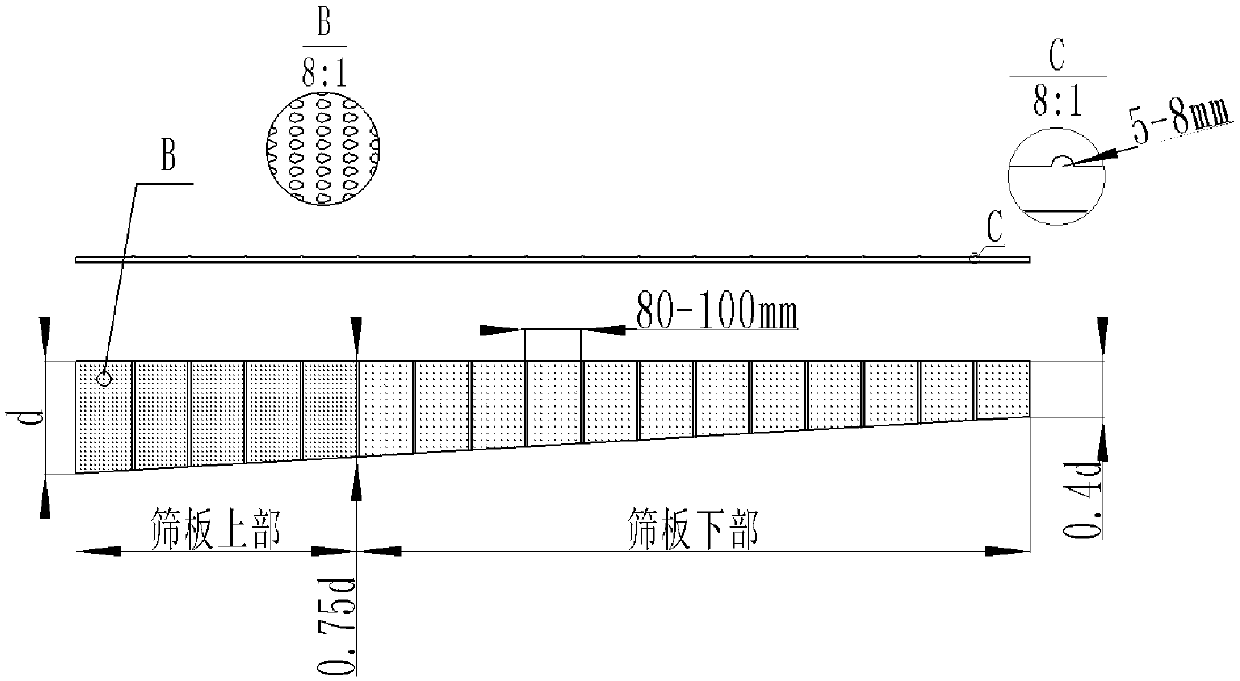

[0022] Drying polypropylene particles is an embodiment of the present invention. The polypropylene particles enter the cyclone separation and drying device (I) from the water-containing material inlet, and realize the solid-liquid separation through the double-layer spiral filter flow channel. At the same time, the air supply device (II) The cyclone separation and drying device (I) continuously provides dry hot air to dry the water-containing particles in the cyclone separation and drying device (I) to obtain polypropylene particles with lower water content and achieve efficient solid-liquid separation at the end of hydraulic conveying.

[0023] First, turn on the fan (5) and the air duct heater (6), and continuously fill the cyclone separation and drying device (I) with dry hot air to exhaust the air from the device and fill it with dry hot air for drying.

[0024] Then turn on the hydraulic conveying device, the polypropylene particles with high water content enter the device from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com