Motor casing with layered long flow channels

A technology of motor casing and flow channel, applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve problems such as noise reduction of motor casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

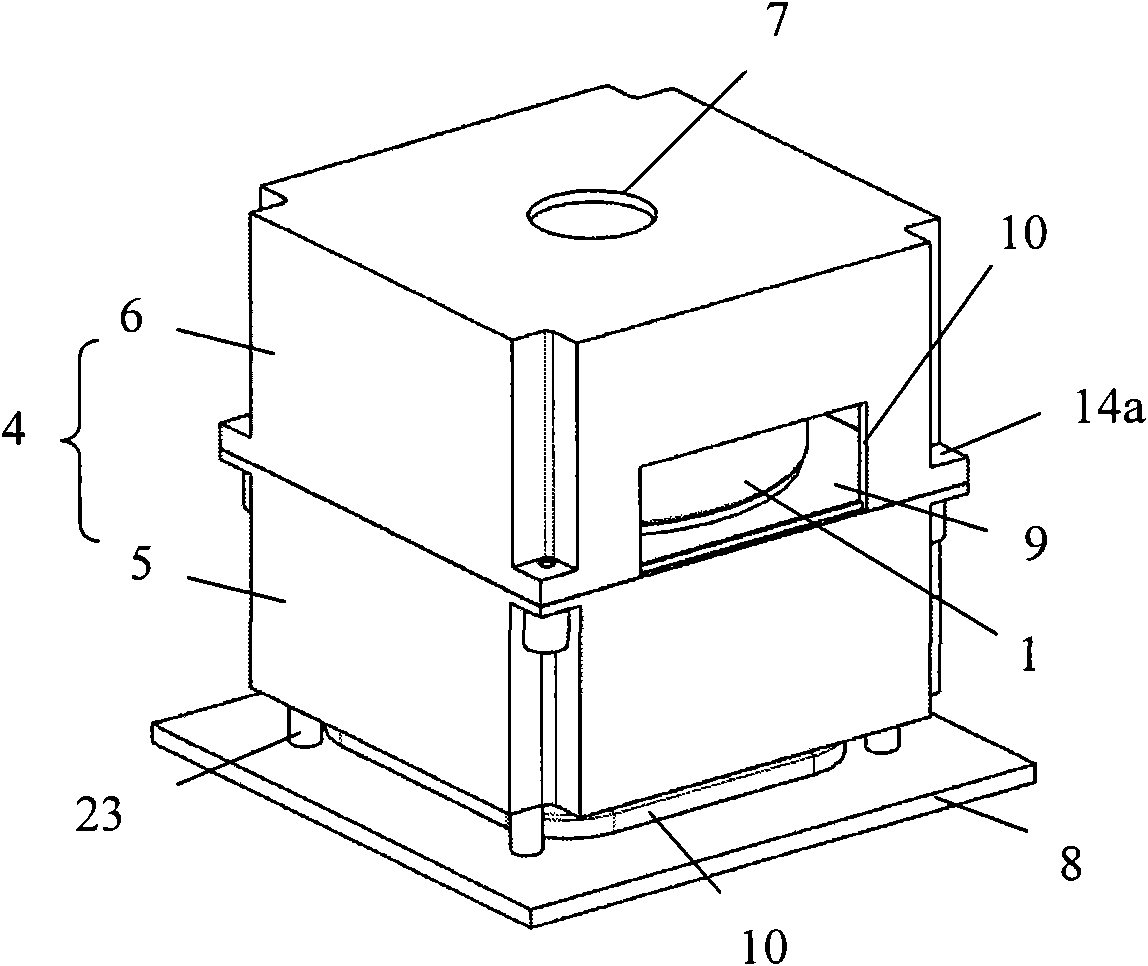

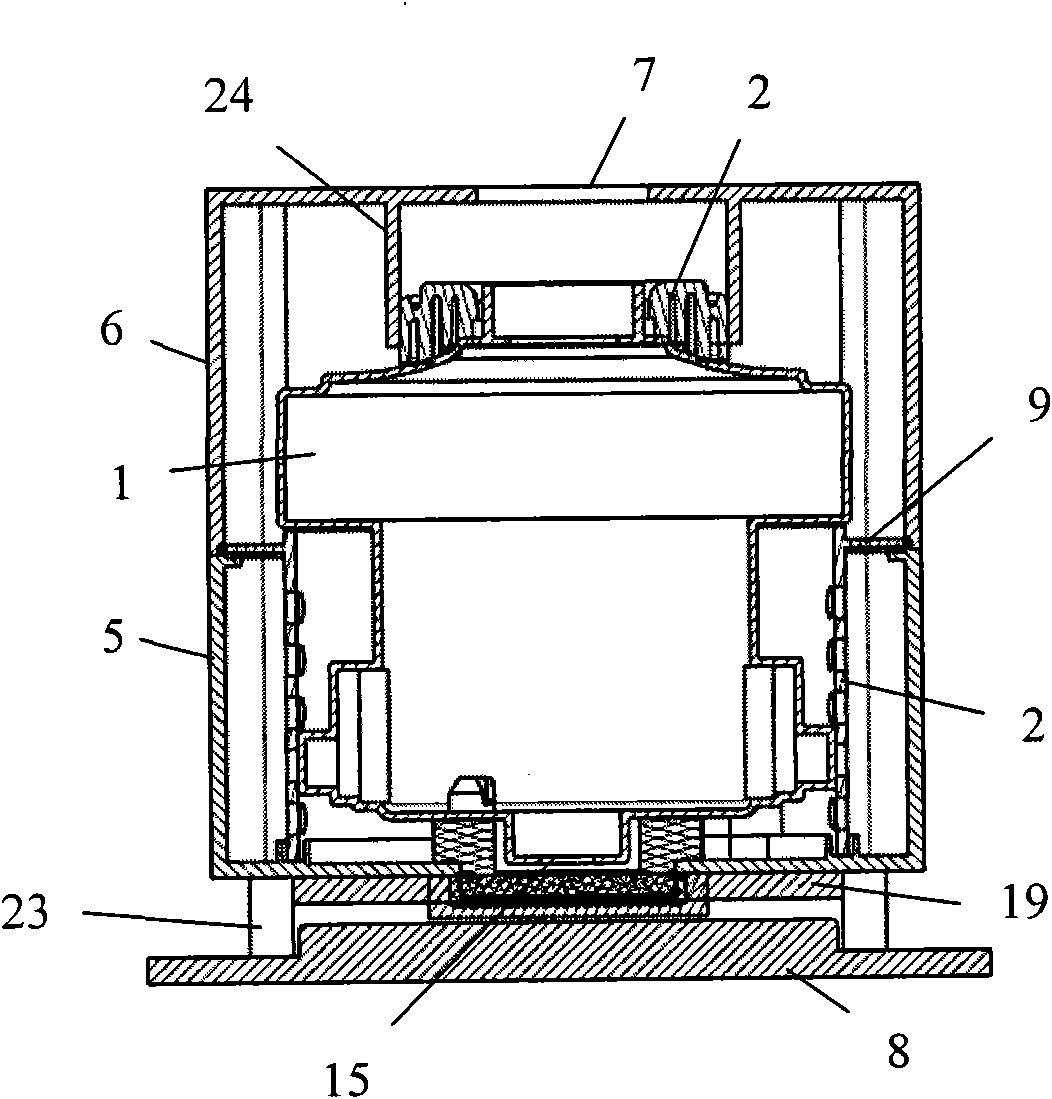

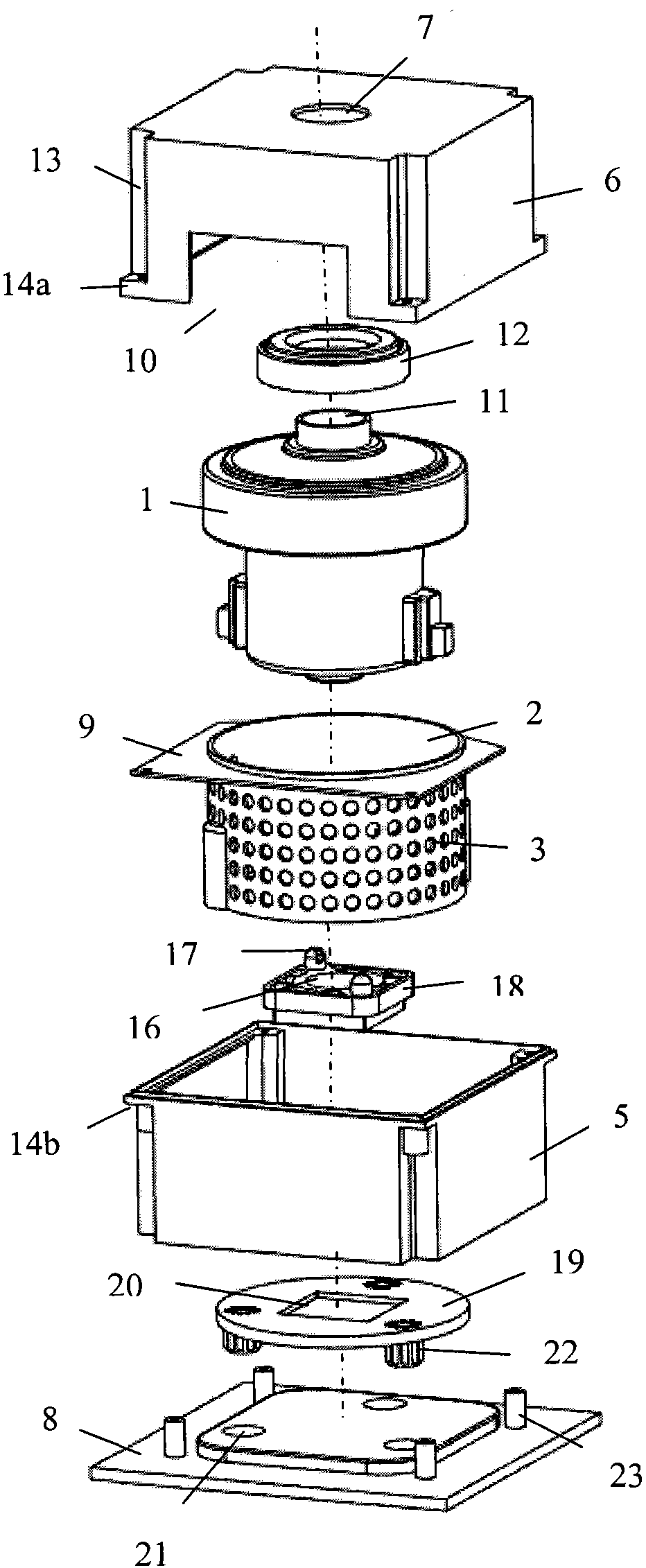

[0047] Figure 7 It is a schematic diagram of the longitudinal section structure of the present invention; Figure 8 It is a schematic diagram of the decomposition structure of the present invention; Figure 9 It is a schematic diagram of an exploded structure of another embodiment of the present invention.

[0048] Inside the body (not shown) of the horizontal vacuum cleaner, the dust collection motor 1 is installed in the inner shell 2, and uniformly distributed ventilation holes 3 are formed on the peripheral wall of the inner shell 2 on one side passing the center line of the circle center. The outside of the inner shell 2 is also provided with a square shell 4 keeping a certain space distance therefrom, and the shell 4 is formed by combining the outer shell 5 and the shell cover 6 . The four corners of the outer shell 5 and the outer shell 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com