A casing type gas electric heating device

An electric heating device and sleeve-type technology, which is applied in the field of gas electric heaters and sleeve-type gas electric heating devices, can solve the problems of limited thickness of insulation layer, low heat exchange efficiency, large gas temperature fluctuations, etc., and achieve heating speed Fast, increased heat exchange area, large heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

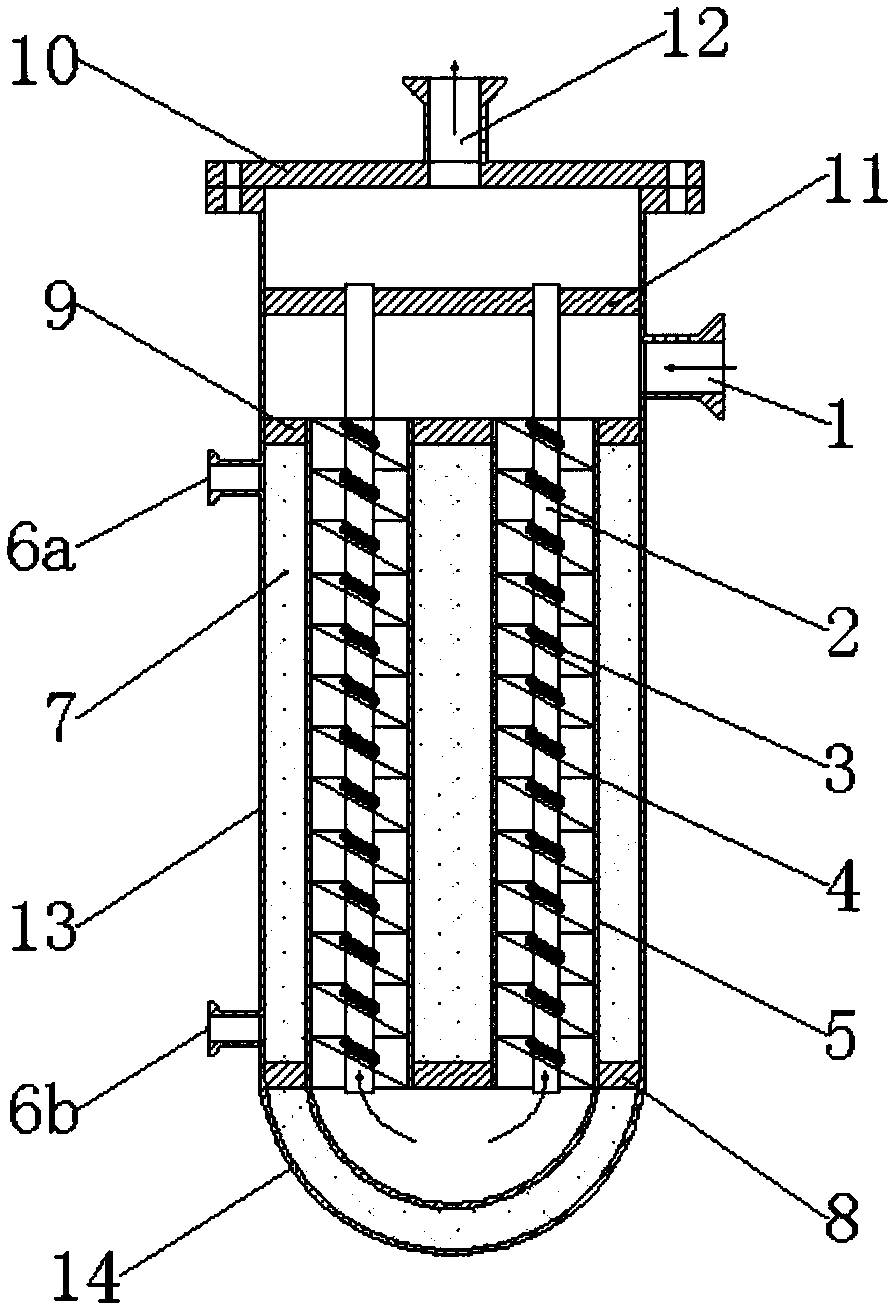

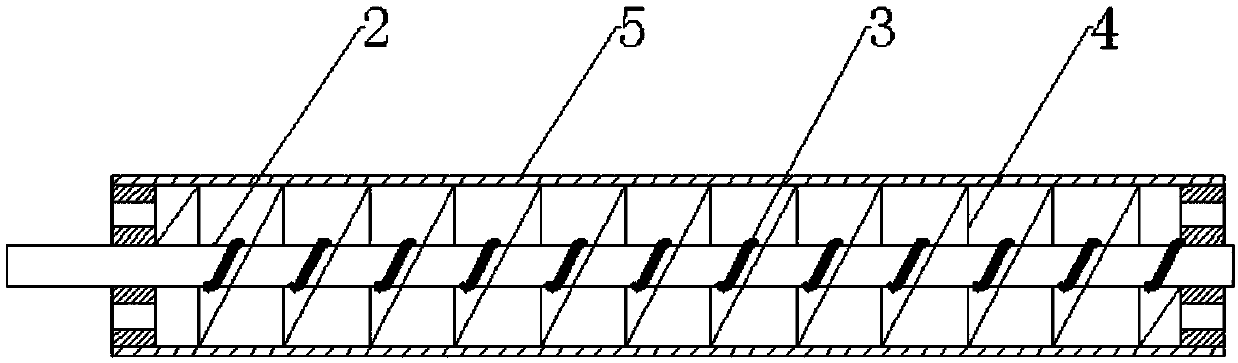

[0016] Such as figure 1 As shown, the present invention is a sleeve-type gas electric heating device, which is especially suitable for heating high-speed flowing gas in a gas pipeline under pressure. The present invention will be further described below with reference to the accompanying drawings. A sleeve-type gas electric heating device, including an air inlet 1, an inner tube 2, a heating wire 3, a fin 4, an outer tube 5, a power cord inlet 6a, a power cord outlet 6b, an insulating layer 7, and a lower tube Plate 8 , middle tube plate 9 , upper end cover 10 , upper tube plate 11 , air outlet 12 , shell 13 and lower end cover 14 .

[0017] The present invention is a sleeve-type gas electric heating device. The gas flow channel adopts a sleeve-type structure design. The sleeve is divided into two layers, including an outer tube 5 and an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com