Steel structure column convenient to adjust

A steel structure and support column technology, applied in the field of steel structure columns, can solve the problems of increasing workload, reducing the stability of steel structure columns, complex installation structures, etc., and achieve the effect of avoiding splicing intervals, increasing the use range, and simple installation structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

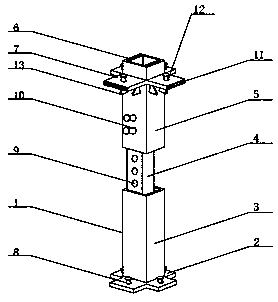

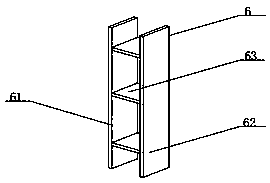

[0017] see Figure 1~2 , in an embodiment of the present invention, a steel structure column that is easy to adjust includes a steel structure column body 1, a base 2 is provided at the bottom of the steel structure column body 1, and a first support column 3 is fixedly installed on the upper surface of the base 2 , the top of the first support column 3 is fixedly installed with the second support column 4, the outside of the second support column 4 is installed with the third support column 5, the upper surface of the base 2 is evenly opened with the first installation hole 8, the first The number of mounting holes 8 is four, and the inside of the first mounting hole 8 is fixedly installed with fixing bolts, the number of the second limiting holes 10 is two, and the second limiting holes 10 are distributed in parallel in the vertical direction, The inside of the second limit hole 10 is fixedly equipped with limit bolts. By setting the second support column 4 and the third sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com