Garbage pyrolysis gasification and secondary combustion chamber integrated device

A technology of pyrolysis gasification and secondary combustion chamber, which is applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of dust-proof baffles affecting the observation line of sight, affecting the observation line of sight, and the small range of fire observation, so as to achieve saving Energy, faster disposal, and floor space savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

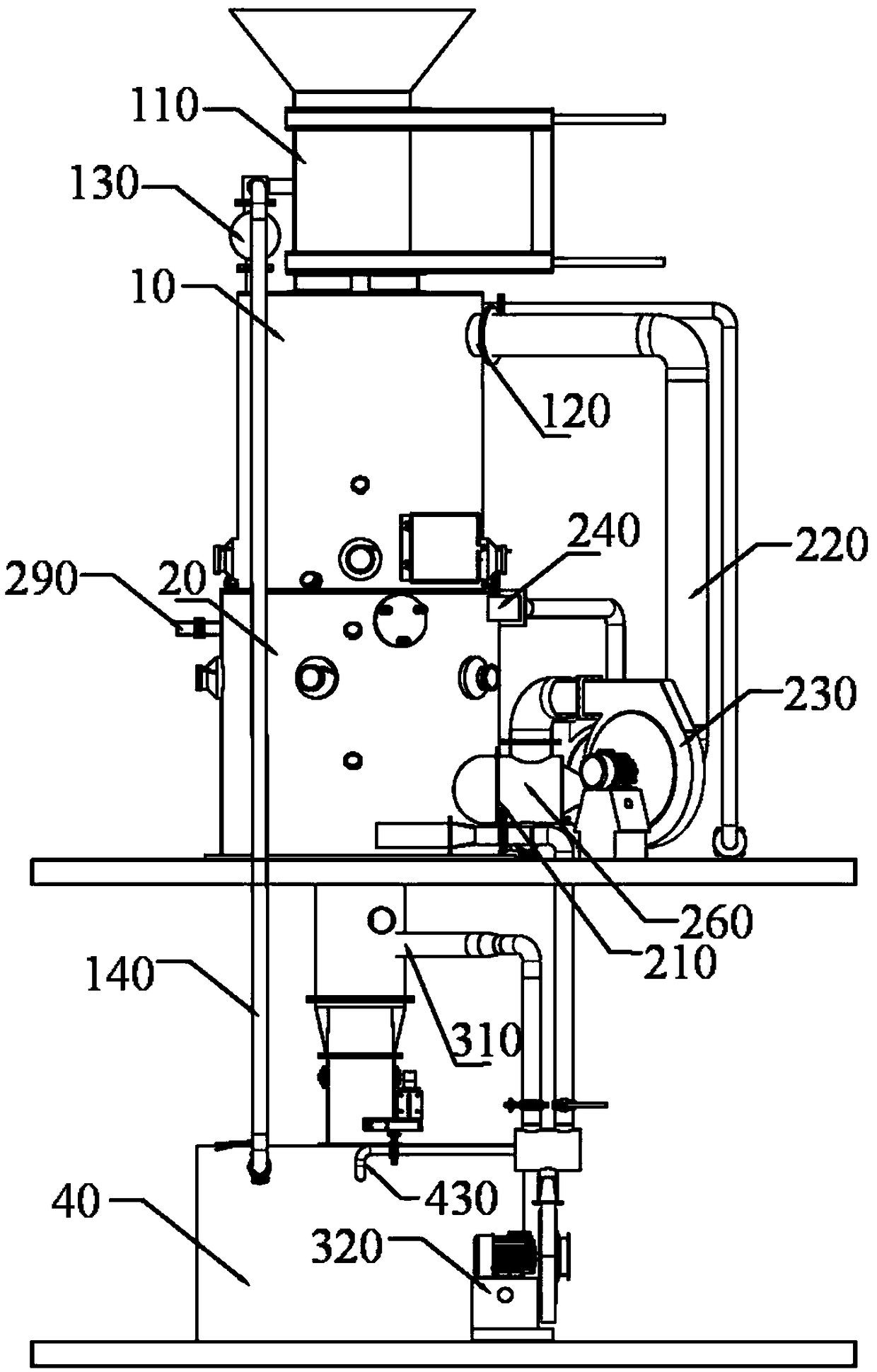

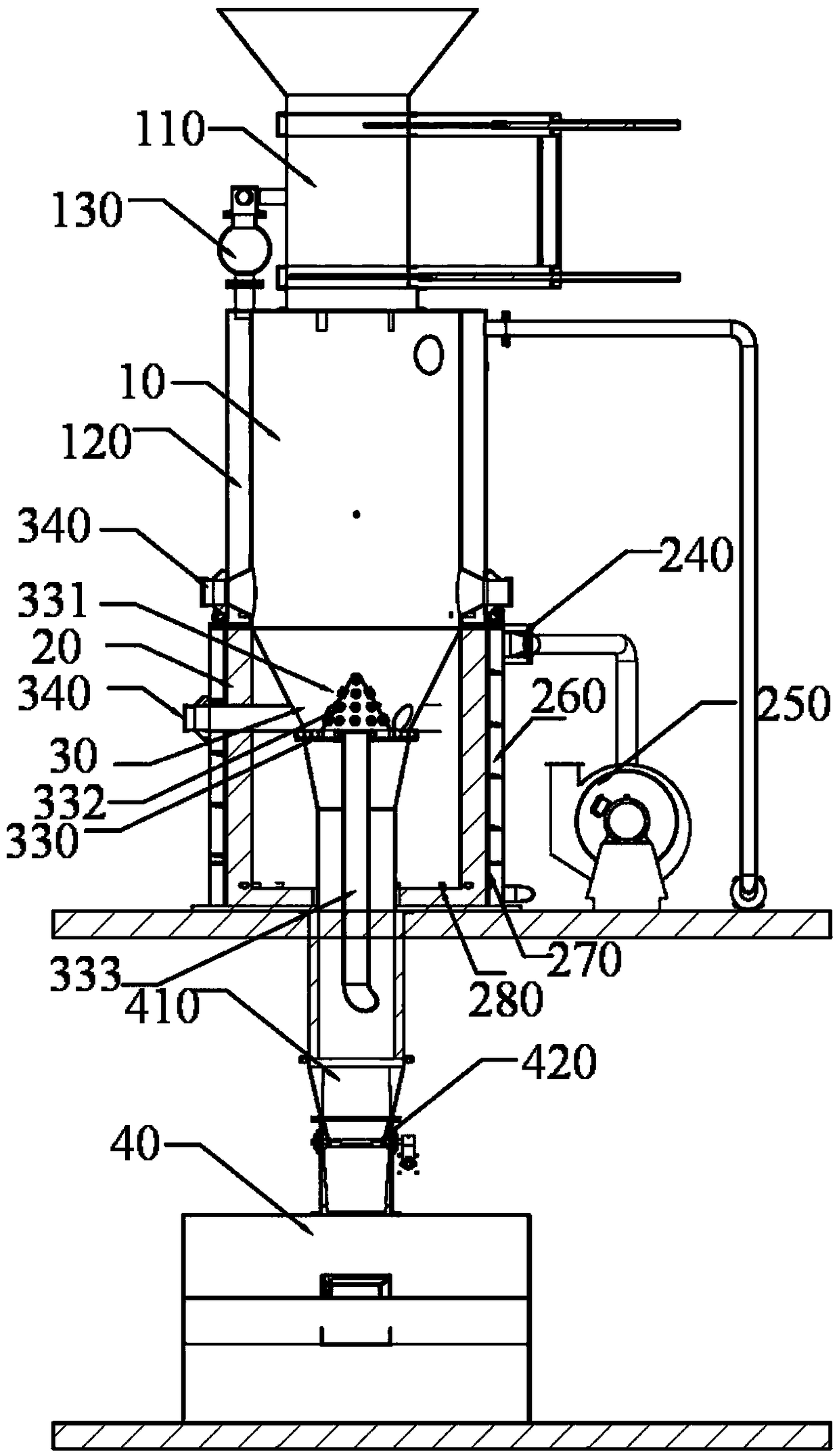

[0029] like figure 1 and 2 as shown,

[0030] A waste pyrolysis gasification and secondary combustion chamber integrated device, comprising:

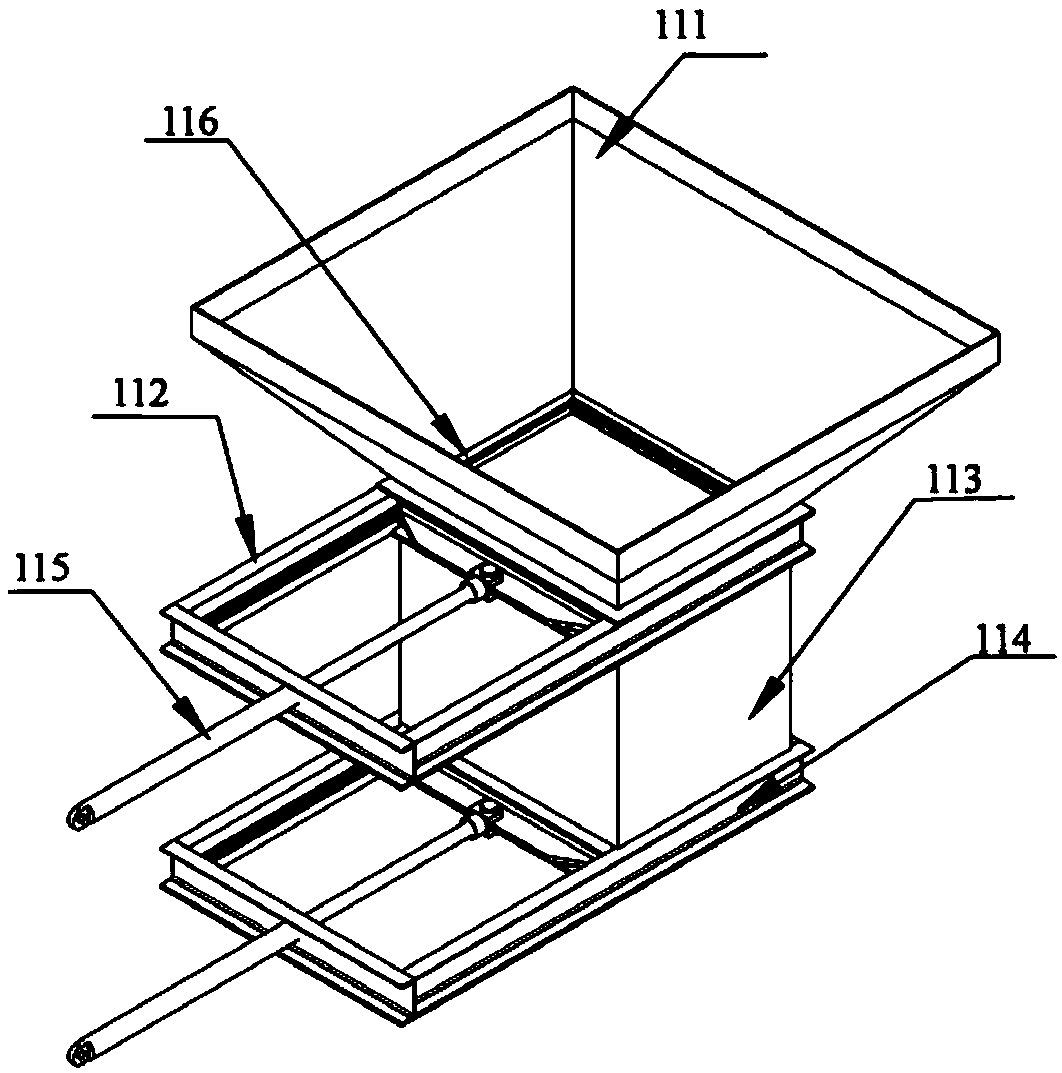

[0031] A gasification furnace 10, the top of the gasification furnace 10 is provided with a feeding device 110, and the side wall of the gasification furnace 10 is provided with a flue gas outlet 120;

[0032] The second combustion chamber 20, the second combustion chamber 20 is arranged under the gasification furnace 10 and is fixedly connected with the gasification furnace 10, the side wall of the second combustion chamber 20 is provided with a flue gas inlet 210, and the flue gas inlet 210 and the flue gas outlet 120 pass through the flue 220 is connected, and the flue 220 is provided with a first fan 230 and a combustion furnace 260;

[0033] Conical cylinder 30, which is arranged in the second combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com