A pressurized limit alarm and its realization method

An implementation method and a technology for an alarm, which are applied in the field of alarms, can solve problems such as inaccurate data and inconvenient operation, and achieve the effects of accurate displacement detection, convenient disassembly and assembly, and reduced failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

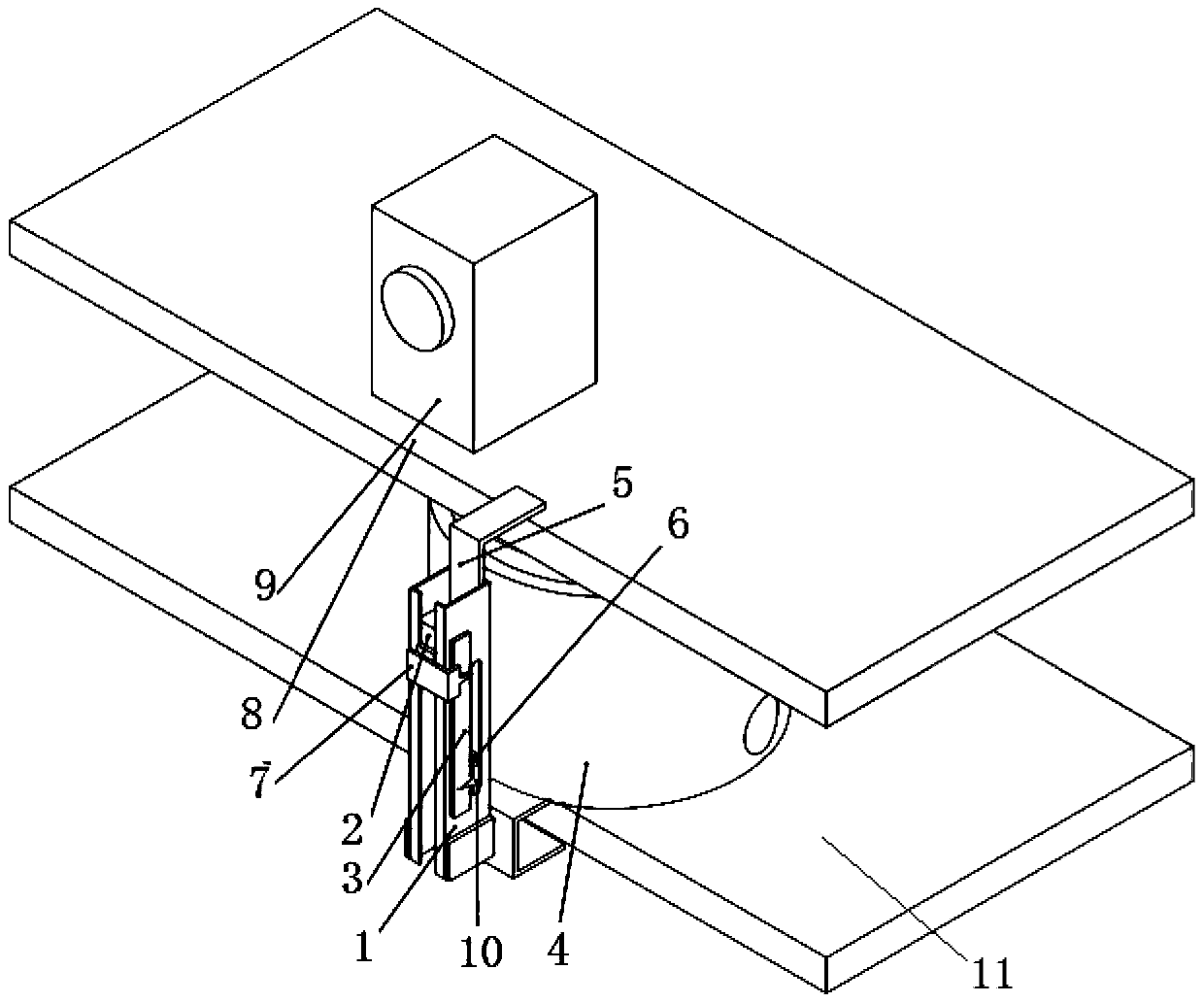

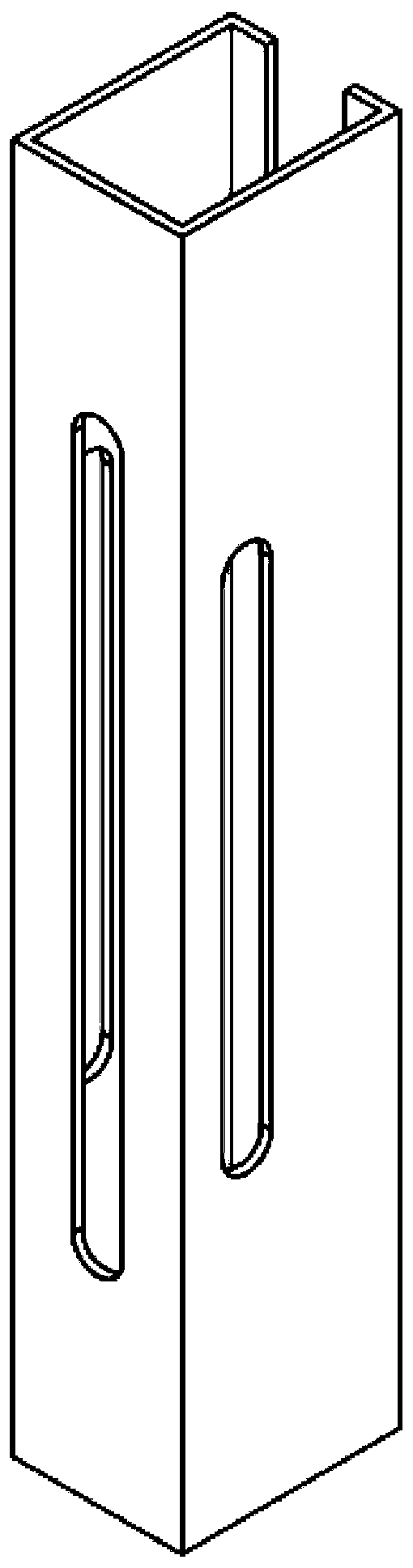

[0025] Such as figure 1 As shown, a pressurized limit alarm of the present invention comprises a body pressure plate 11, a pressurized oil cylinder 4, a scale unit and an alarm 9 (it is placed together with a power supply, and the power supply adopts a battery or a rechargeable power supply to supply power to the electrical components ), wherein the body pressure plate 11 is placed on the top of the body, the pressurized oil cylinder 4 is installed between the body pressure plate and the upper clamp 8, and the mobile bracket 1 part of the scale unit is installed on the end of the body pressure plate 1; the scale unit passes Electric wire is connected with alarm 9.

[0026] In this embodiment, the base of the pressurized oil cylinder 4 is fixedly installed on the pressure plate 11 of the device body, and the piston rod of the pressurized oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com