Elevator traction mechanism

An elevator traction and traction machine technology, which is applied to elevators, elevators in buildings, and lifting equipment in mines, etc., can solve the problems of difficulty in reliable braking and low safety, and achieve reliable braking and avoid topping. or squat to avoid the effect of contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

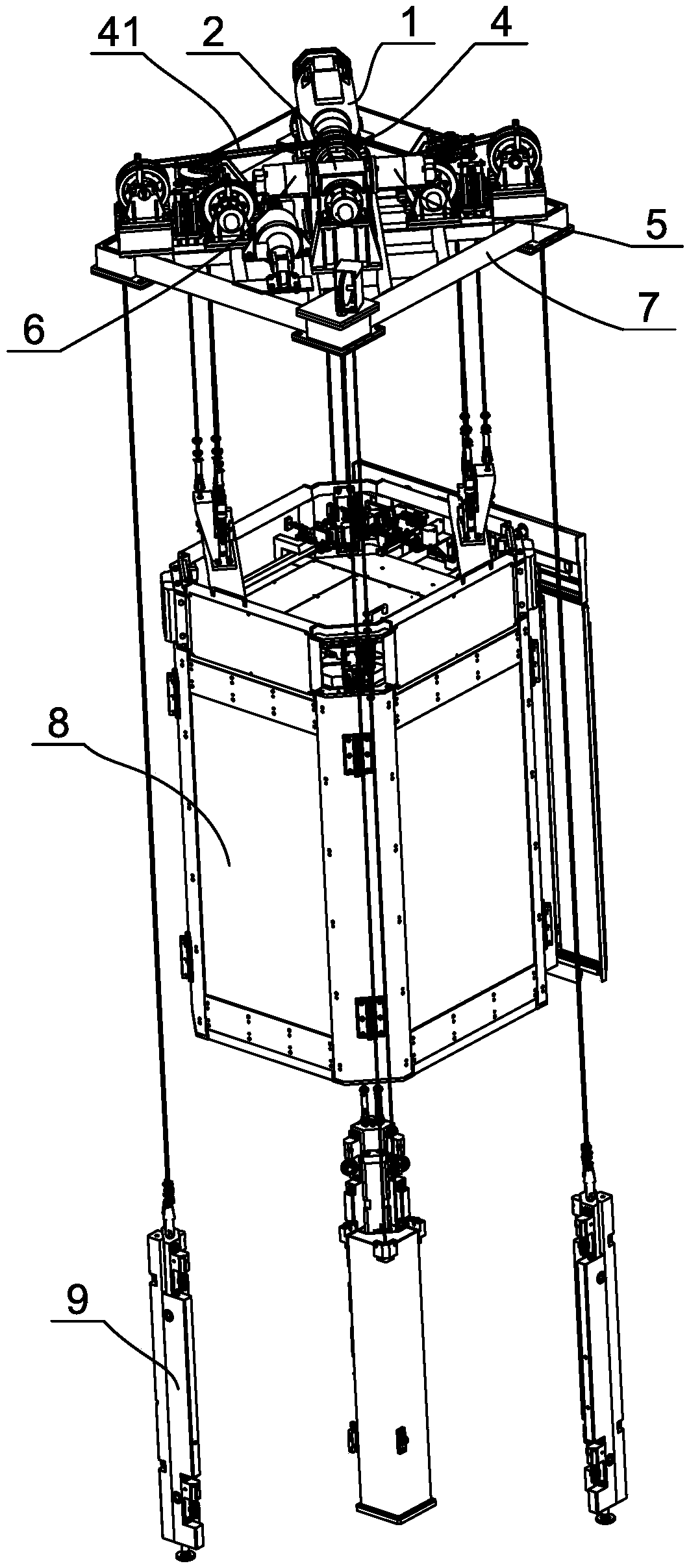

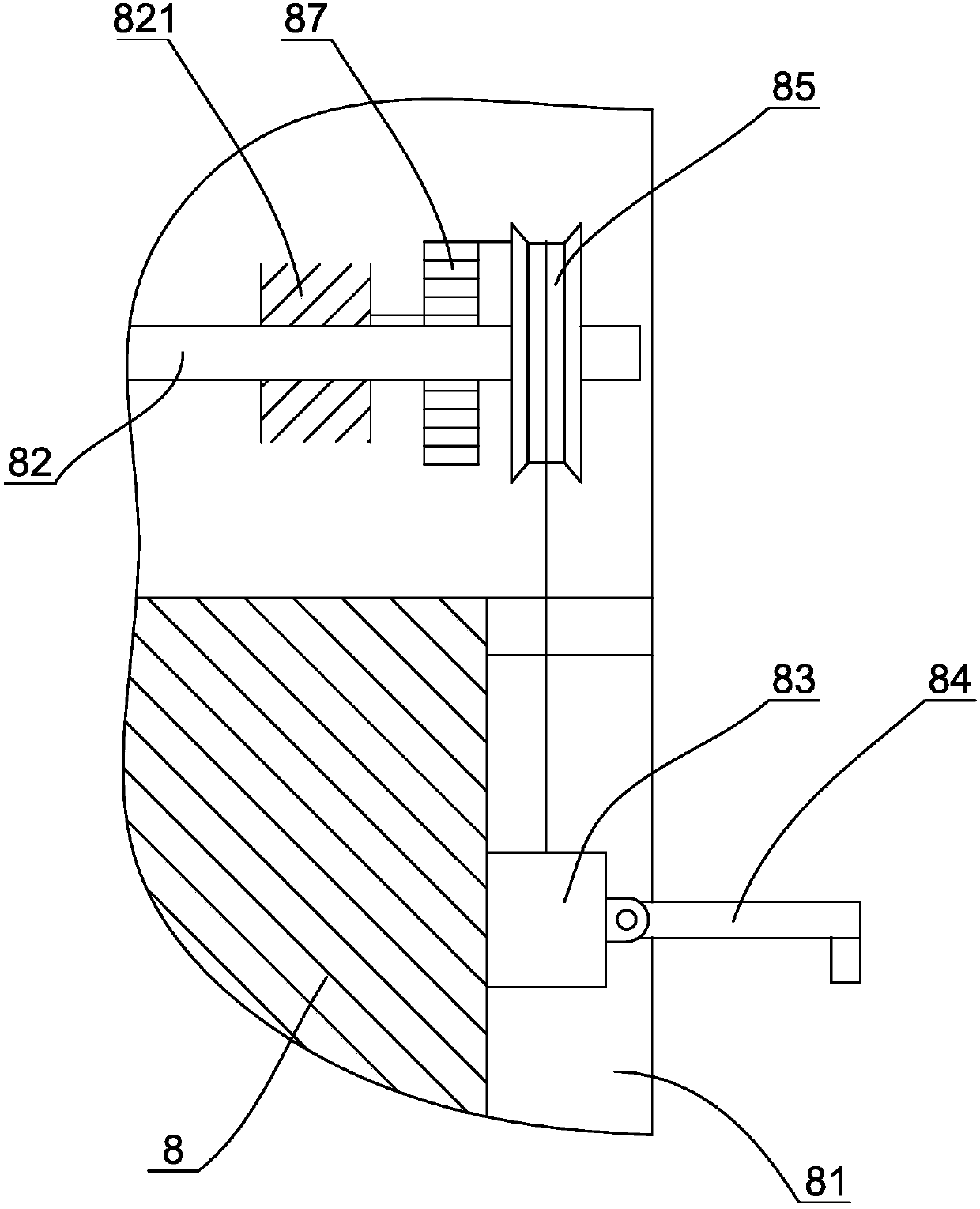

[0033] like figure 1 As shown, an elevator traction mechanism includes a traction machine 1 arranged on the installation platform 7 at the top of the elevator shaft. The traction machine adopts a servo motor to precisely control its speed. The traction machine is configured to drive the car Lifting power source. A traction sheave 4 is coaxially connected to the output shaft of the traction machine, and a traction rope 41 is wound around the traction sheave. One end of the traction rope is connected to the car 8 after bypassing the diverting pulley, and the other end of the traction rope One end bypasses the diverting pulley and is connected to the counterweight 9, and the traction wheel and the traction rope together constitute an action actuator that drives the car to go up and down. When the traction machine outputs torque to drive the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com