A device and method for non-stop steam turbines in waste heat power plants in iron and steel plants

A steam turbine, steel plant technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., to achieve the effect of easy operation, avoiding valuable time, and avoiding frequent shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

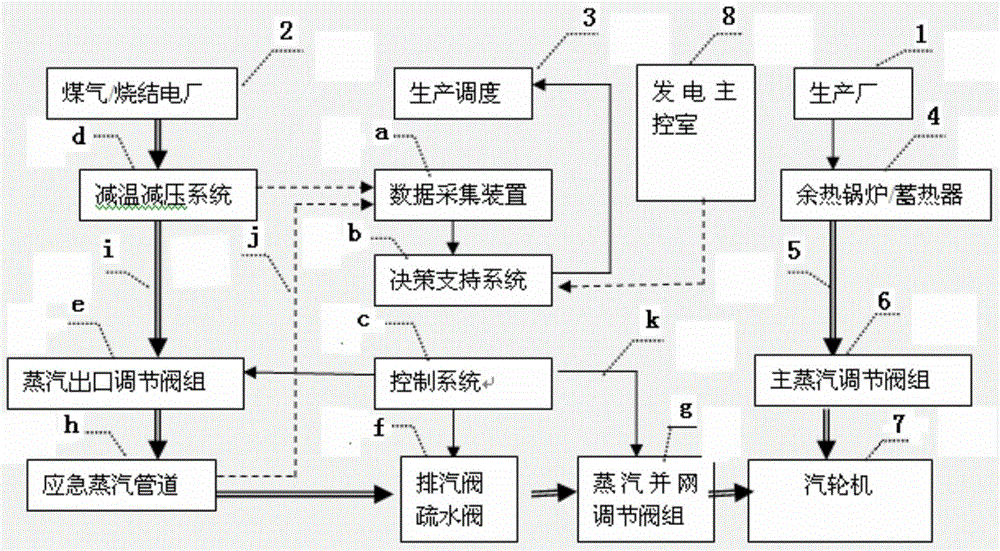

[0008] Attached below figure 1 Further describe in detail the device and method for non-stop steam turbines in waste heat power plants in iron and steel plants according to the embodiment of the present invention: figure 1 The example shown: a certain iron and steel factory has three power plants: coal gas power generation, sintering waste heat power generation, and saturated steam power generation. Among them, the installed capacity of gas power generation is 30MW, which is purely fired with blast furnace gas, with a steam pressure of 3.82Mpa and a temperature of 450°C; 6MW, 180m for a single unit 2 Sintering waste heat, steam pressure 2.0Mpa, temperature 350°C; saturated steam power generation installed capacity 6MW, heating steam for three 60t converters and three rolling mills, steam pressure 0.6Mpa, temperature 168°C. Now it is divided into four situations: sintering failure, sintering maintenance, steelmaking failure, and steelmaking maintenance, respectively as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com