Double-machine traction device

A traction and traction sheave technology is applied in the field of double-machine traction devices, which can solve the problems of insufficient braking force, low braking reliability, low elevator safety, etc., so as to avoid safety accidents and ensure reliable braking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

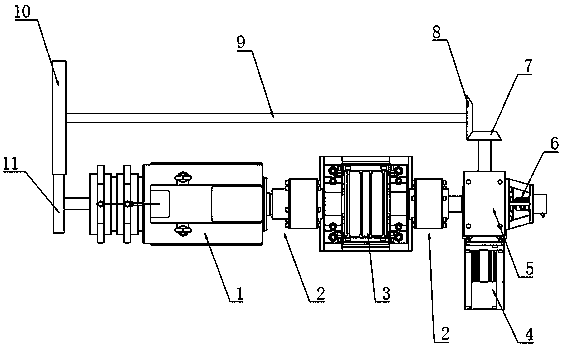

[0030] Embodiment 1: An elevator double machine traction device (see figure 1 ), including traction machine 1, traction wheel 3, worm gear mechanism 5, rescue motor 4 and synchronous mechanism.

[0031] The traction machine is arranged on the installation platform at the top of the elevator shaft. The traction machine in this embodiment adopts a servo motor. The servo motor can accurately control the speed, and the traction machine is used as the power source for the lifting of the car. The traction machine adopts a two-way transmission structure, the output of one end is coaxially connected with the traction wheel through the coupling 2, and the other end is connected with the synchronous mechanism. The other side of the traction sheave is connected with the worm gear mechanism through a coupling. A traction rope is wound around the traction sheave, one end of the traction rope is connected to the car after passing around the diverting pulley, and the other end of the tracti...

Embodiment 2

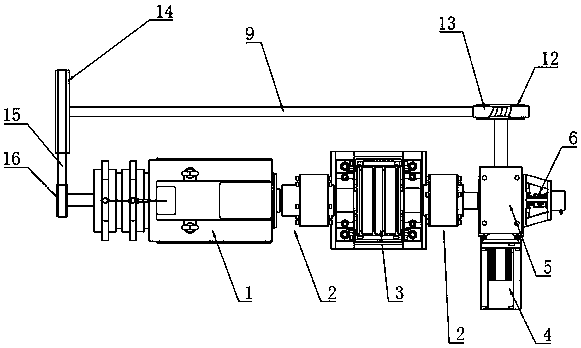

[0035] Embodiment 2: An elevator double machine traction device (see figure 2 ), including traction machine 1, traction wheel 3, worm gear mechanism 5, rescue motor 4 and synchronous mechanism.

[0036] The synchronous mechanism includes a transmission rod 9, which is parallel to the rotation axis of the traction wheel, and the transmission rod and the worm are connected through a transmission mechanism that can change the transmission direction by 90°. In this embodiment, the transmission mechanism that can change the transmission direction by 90° adopts a worm gear. The worm gear 12 is connected with the worm in the worm gear mechanism, and the worm 13 is connected with the end of the transmission rod. The output terminal of the lead machine is connected. A driven pulley 14 is fixed at the end of the transmission rod, a driving pulley 16 is fixed at the output end of the traction machine, and a timing belt 15 is connected between the driving pulley and the driven pulley. ...

Embodiment 3

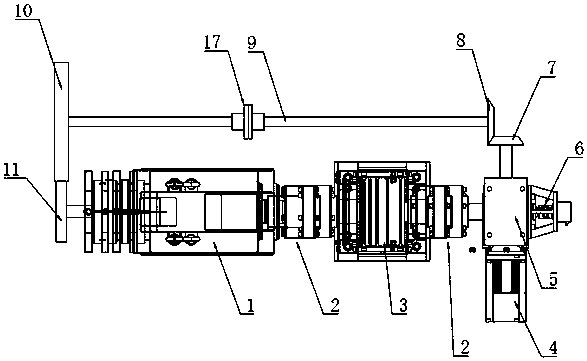

[0039] Embodiment 3: An elevator double machine traction device (see image 3 ) is different from Embodiment 1 in that the transmission rod 9 is provided with a clutch. The clutch in this embodiment adopts an electromagnetic clutch 17. When the power is applied, the clutch maintains the transmission, and the synchronous mechanism drives the worm to rotate synchronously without causing lock to the worm gear. stop; when there is no electricity, the clutch disconnects the transmission. At this time, the synchronous mechanism has no power input, and will not drive the worm to rotate, and the worm will lock the worm wheel, and finally lock the traction sheave. Refer to Example 1 for all the other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com