Gravity columnar sediment sampler

A sampler and sediment technology, which is applied to the sampling device and other directions, can solve the problems of insufficient cable length, knotting and high cost, and achieves the effect of satisfying sampling requirements, reasonable structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

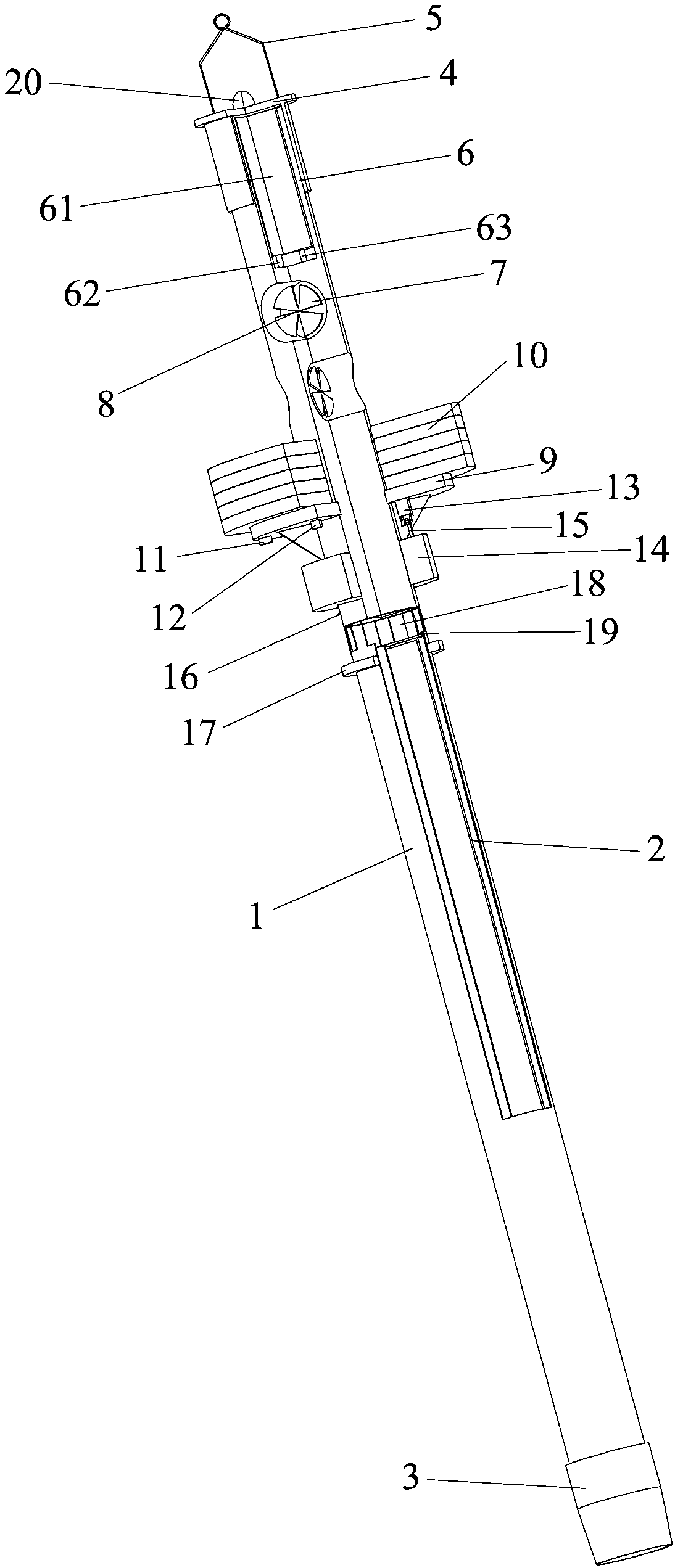

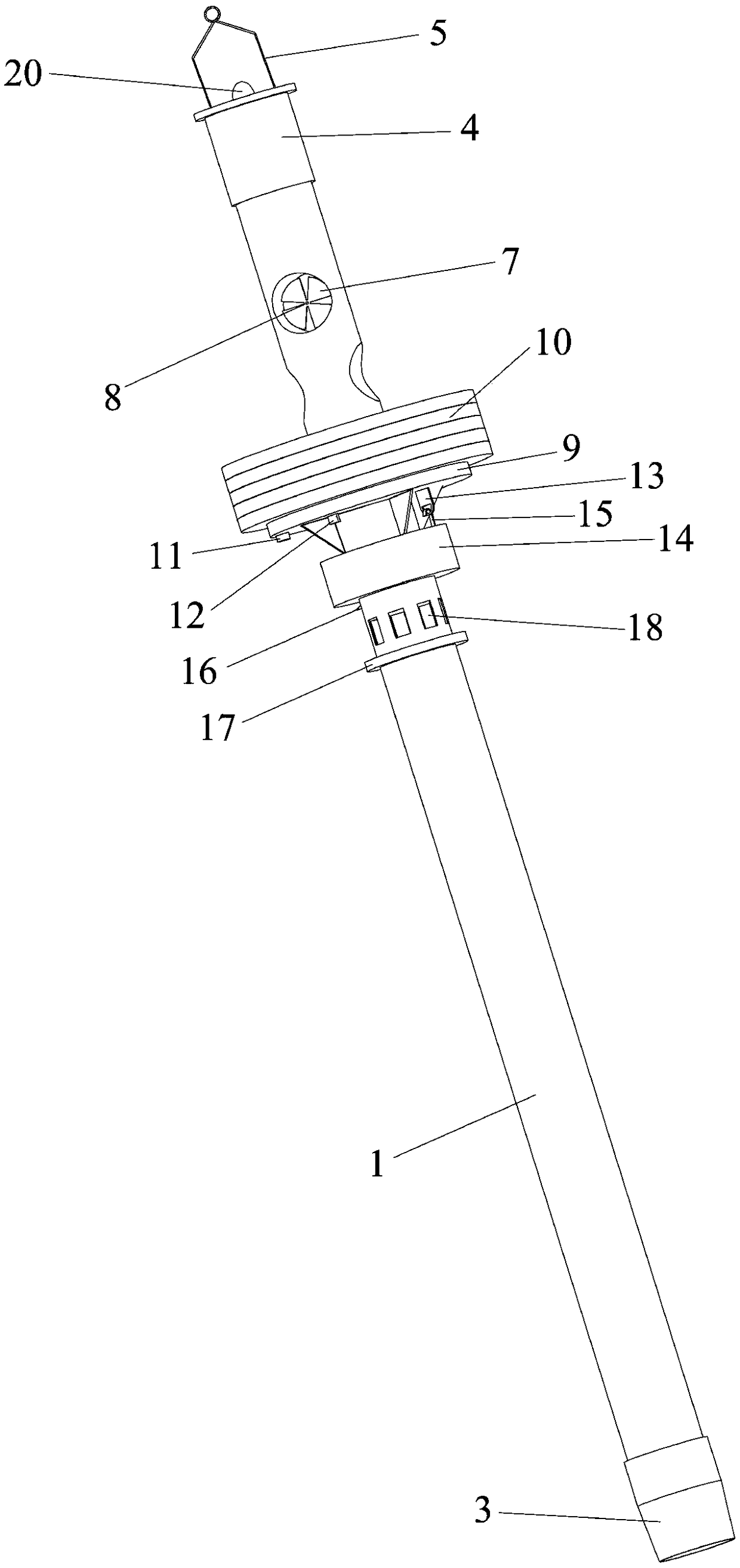

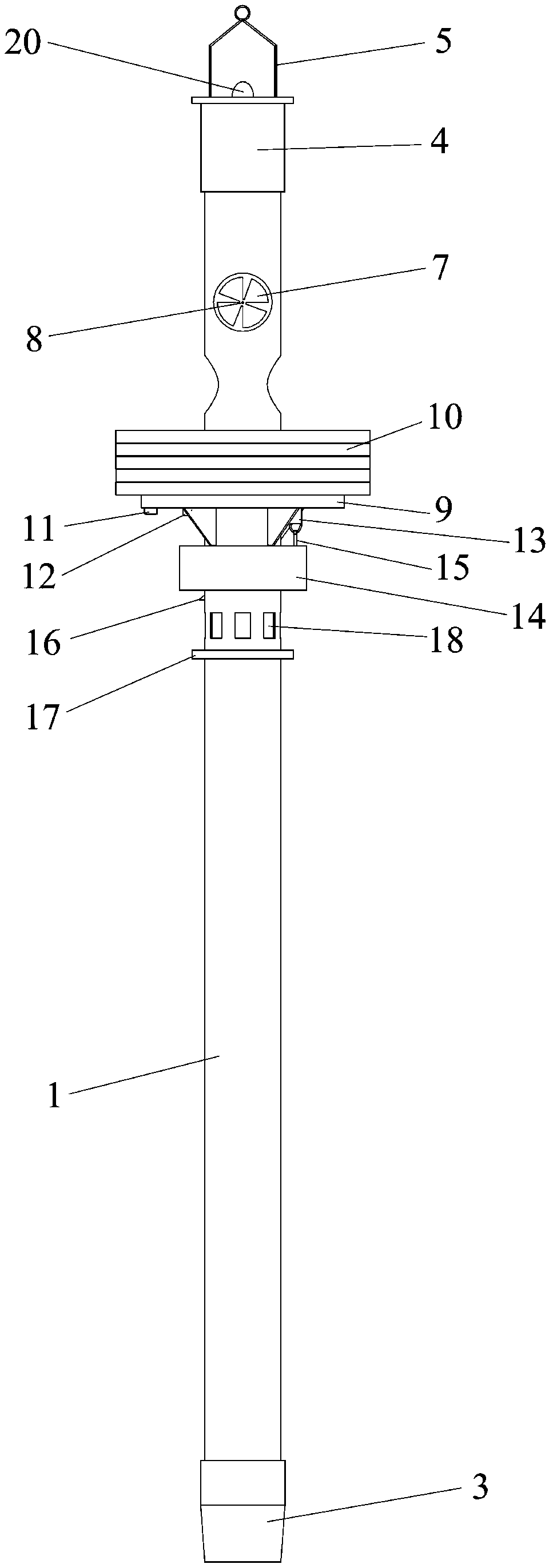

[0040] A gravity columnar sediment sampler such as figure 1 , 5 As shown, the sampling tube 1 is divided into three parts, the lower part is a hollow tubular structure, the middle part is a solid structure, and the top is a pressure-resistant sealed cabin 6; The device is used to prevent sample loss, and the hollow tubular structure part of the sampling tube 1 is equipped with a sample tube 2;

[0041] Such as Figure 1-6 As shown, there are one or more drain windows 18 on the top side wall of the hollow tubular part of the sampling tube 1, and a position for limiting is provided on the inner wall of the hollow tubular part of the sampling tube 1, below the drain window 18 and above the sample tube 2. The sample tube snap ring 19 is provided with a limit ring 17 on the outer wall of the sampling tube 1 and below the drain window 18;

[0042] Such as Figure 1-4 As shown, the solid structure part of the sampling pipe 1 is provided with a bearing seat 9, the bearing seat 9 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap