Core tube beam column structure for constructional engineering

A construction technology, tube-beam-column technology, applied in the direction of building components, special structures, electrical components, etc., can solve problems such as hindering installation and maintenance, entangled cables, entangled wires or cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

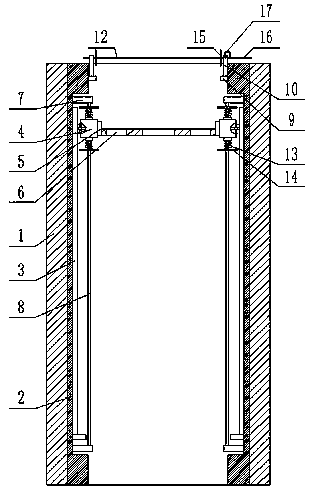

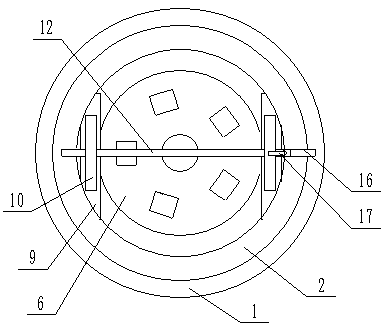

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

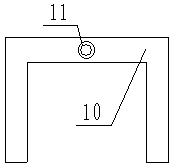

[0021] Such as Figures 1 to 3 As shown, a core tube beam-column structure for a construction project according to the present invention includes a frame 1, a cylinder 2, a pair of slide rails 3, a pair of moving trolleys 4, a pair of support seats 5, a fixed plate 6, two For the fixed frame 7 and the pair of poles 8, the cylinder 2 is placed inside the frame 1, the inner side wall of the cylinder 2 is provided with a pair of first grooves, and the pair of slide rails 3 are arranged in the first grooves Inside, the pair of mobile trolleys 4 are placed on the slide rails 3, the pair of support seats 5 are placed on the pair of mobile trolleys 4, the fixed plate 6 is placed on the pair of support seats 5, and the fixed plate 6 There is a circular through hole at the upper center, several rectangular through holes are opened on the fixed plate 6 and outside the first cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com