Sand and stone production system

A production system, sand and gravel technology, applied in the field of machinery, can solve problems such as difficult adjustment, unreasonable gradation, and environmental deterioration of sand making, so as to speed up the speed of dust removal, save the time of dust removal, and improve the efficiency of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

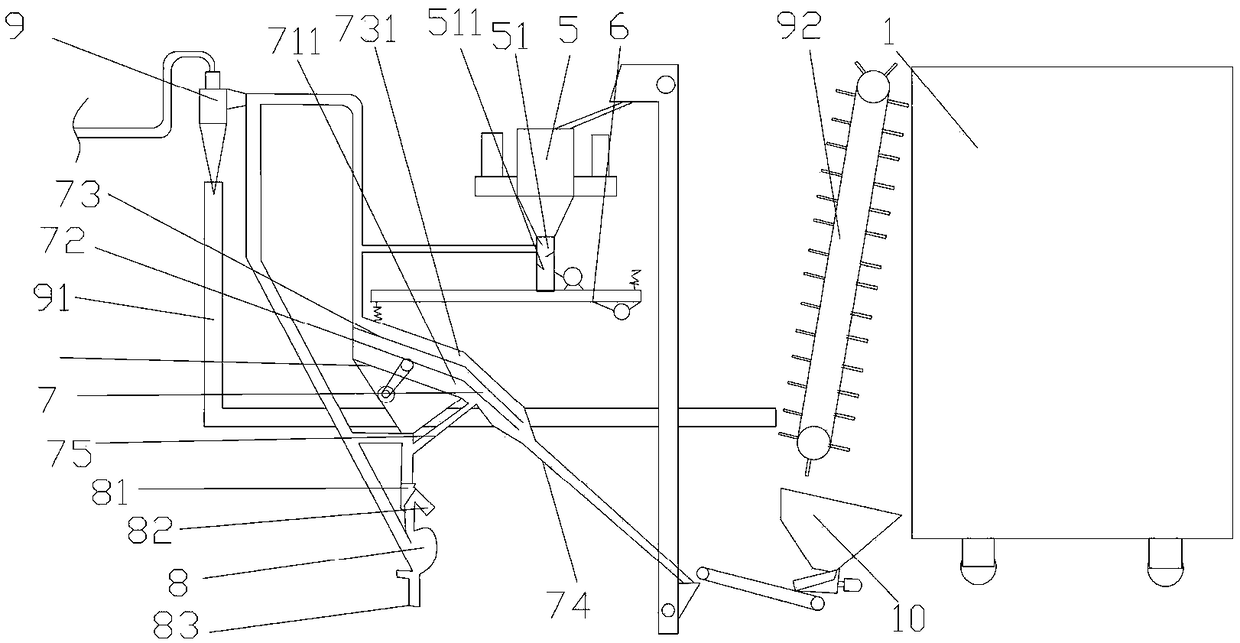

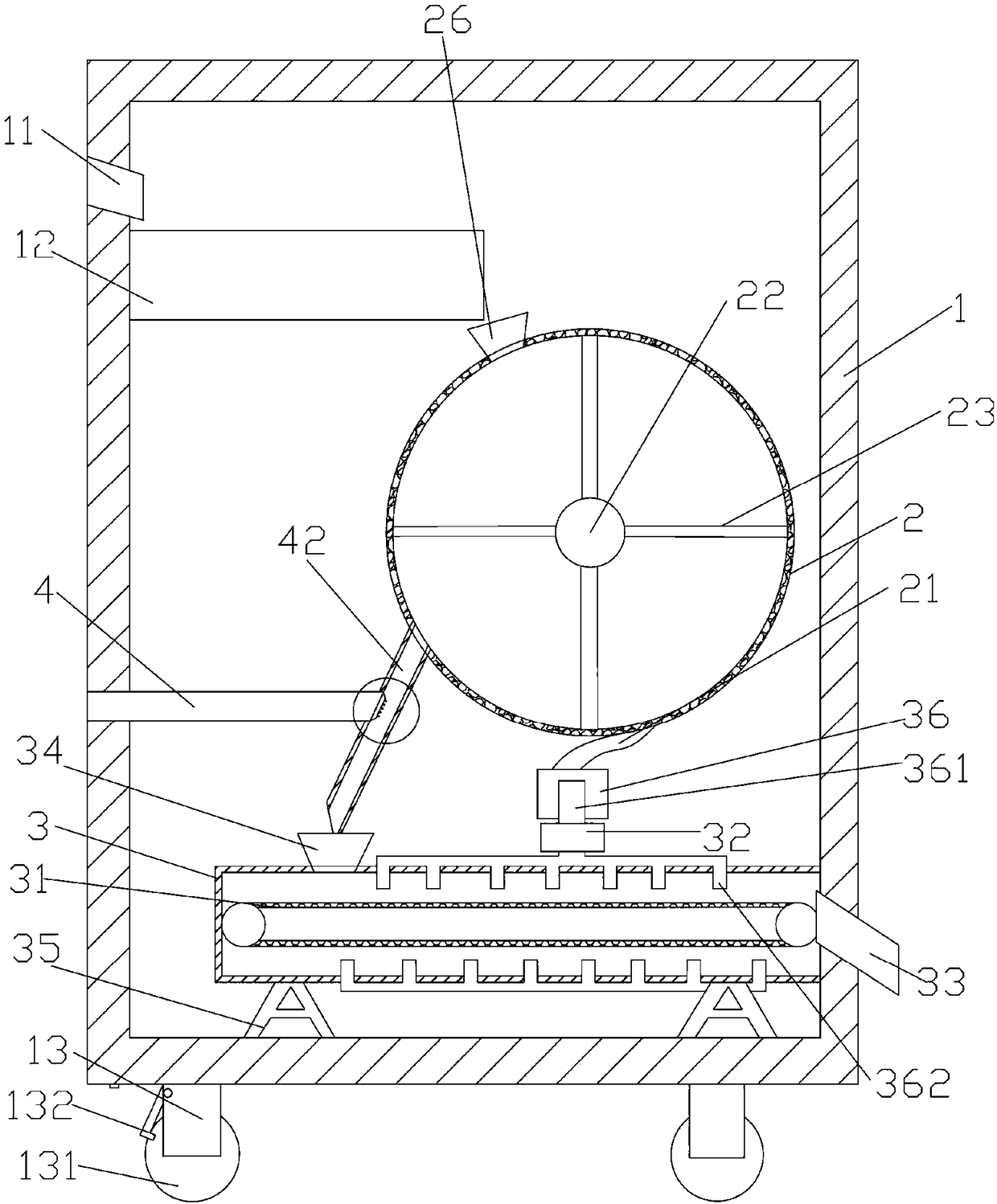

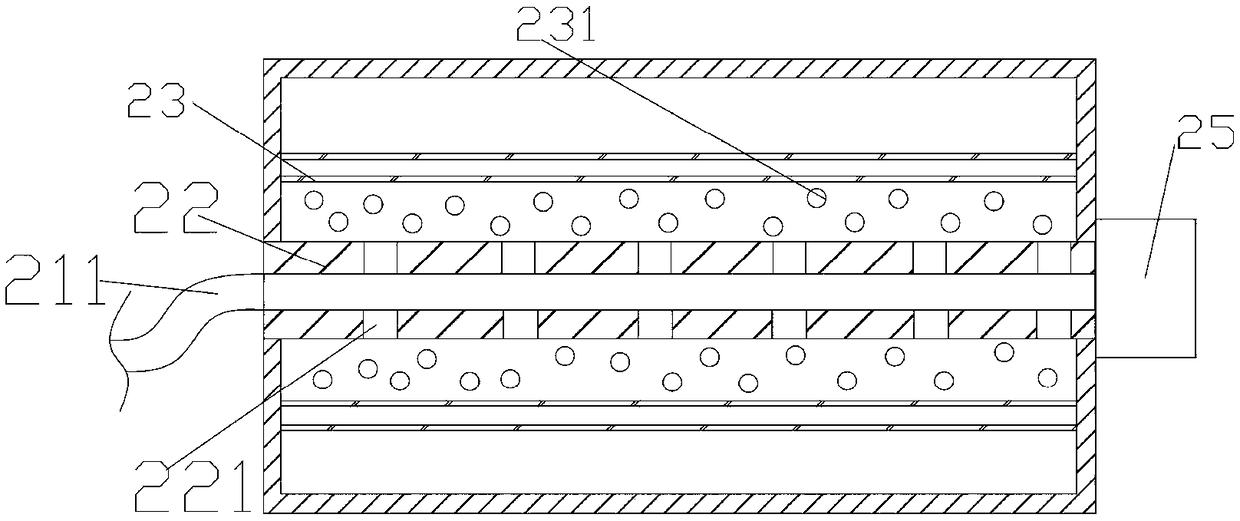

[0017] Such as Figure 1-4 As shown, a sand and gravel production system includes a gravel dust collector 1, a feeder 6, a screening machine 7, and a gravel sorting machine 8. The feeder 6 is provided with a discharge port, and the screening machine 7 A discharge port 711 is provided. The sand and gravel dust remover 1 is arranged at the inlet 11, and the sand and gravel dust remover 1 is provided with an agitating mechanism for driving the diffusion of dust, a humidifying mechanism and a drying mechanism located below the agitating mechanism mechanism.

[0018] A conveying pipe 91 is provided below the filter 9, and a conveying device 92 is provided on one side of the feed port 11. The conveying pipe 91 is connected to the conveying device 92. Through the conveying of the conveying pipe 91, the produced sand and gravel can pass through The conveying device 92 enters the sand and gravel dust collector 1 to perform effective dust removal treatment, which effectively realizes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com