Gravel dust removing equipment

A technology for dust removal equipment and sand and gravel, which is applied to lighting and heating equipment, cleaning methods using liquids, dryers, etc. Speed up and speed up the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

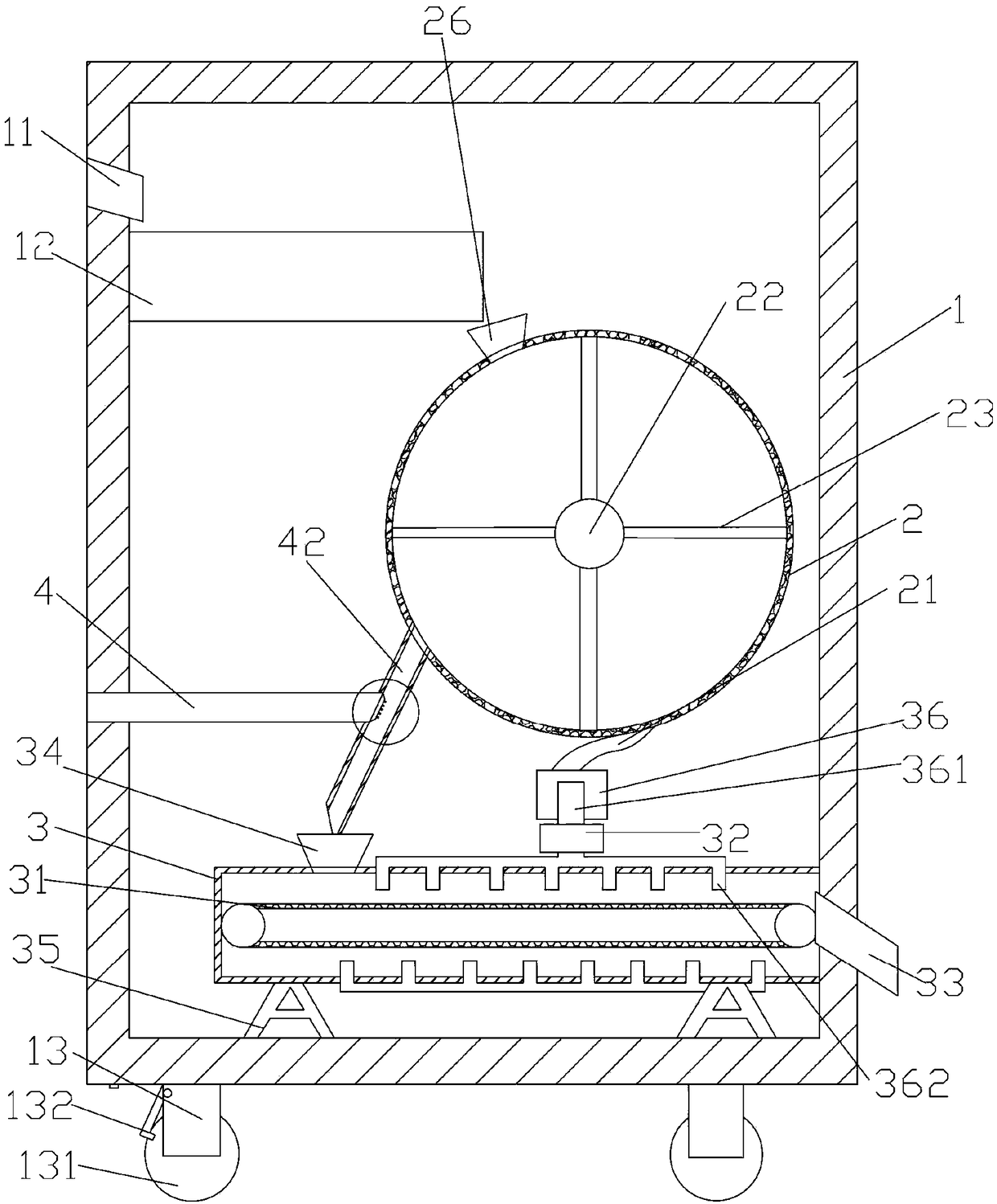

[0018] Such as Figure 1-3 As shown, a sand and gravel dust removal equipment includes a box body 1, and the box body 1 is provided with an agitation mechanism for driving dust diffusion, a humidification mechanism and a drying mechanism arranged below the agitation mechanism, and the drying mechanism passes A support frame 32 is fixed at the bottom of the box body 1, and multiple support frames 32 can be provided to enhance the stability of the drying mechanism.

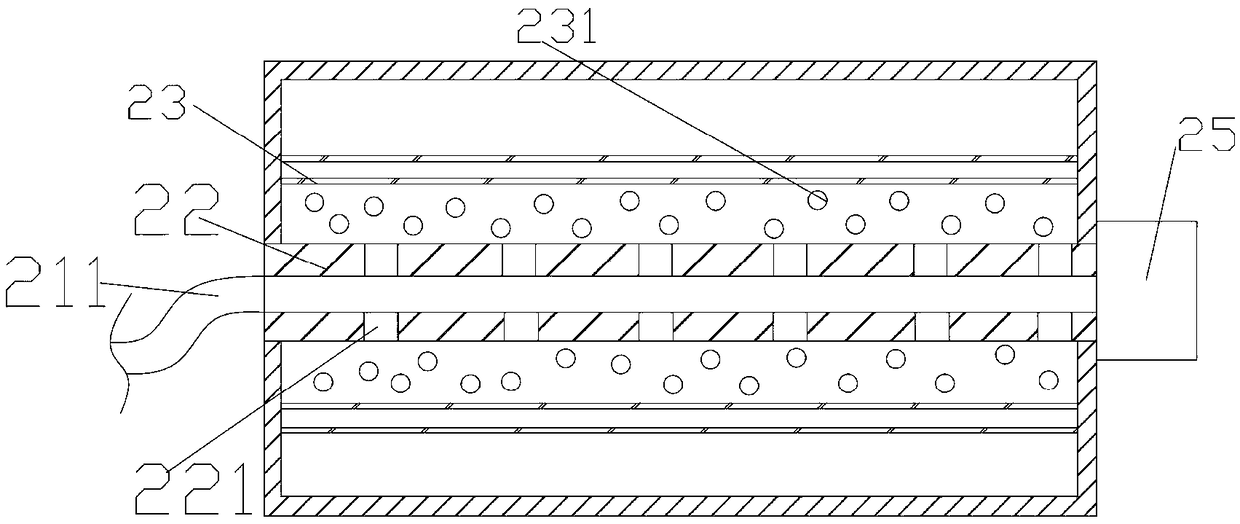

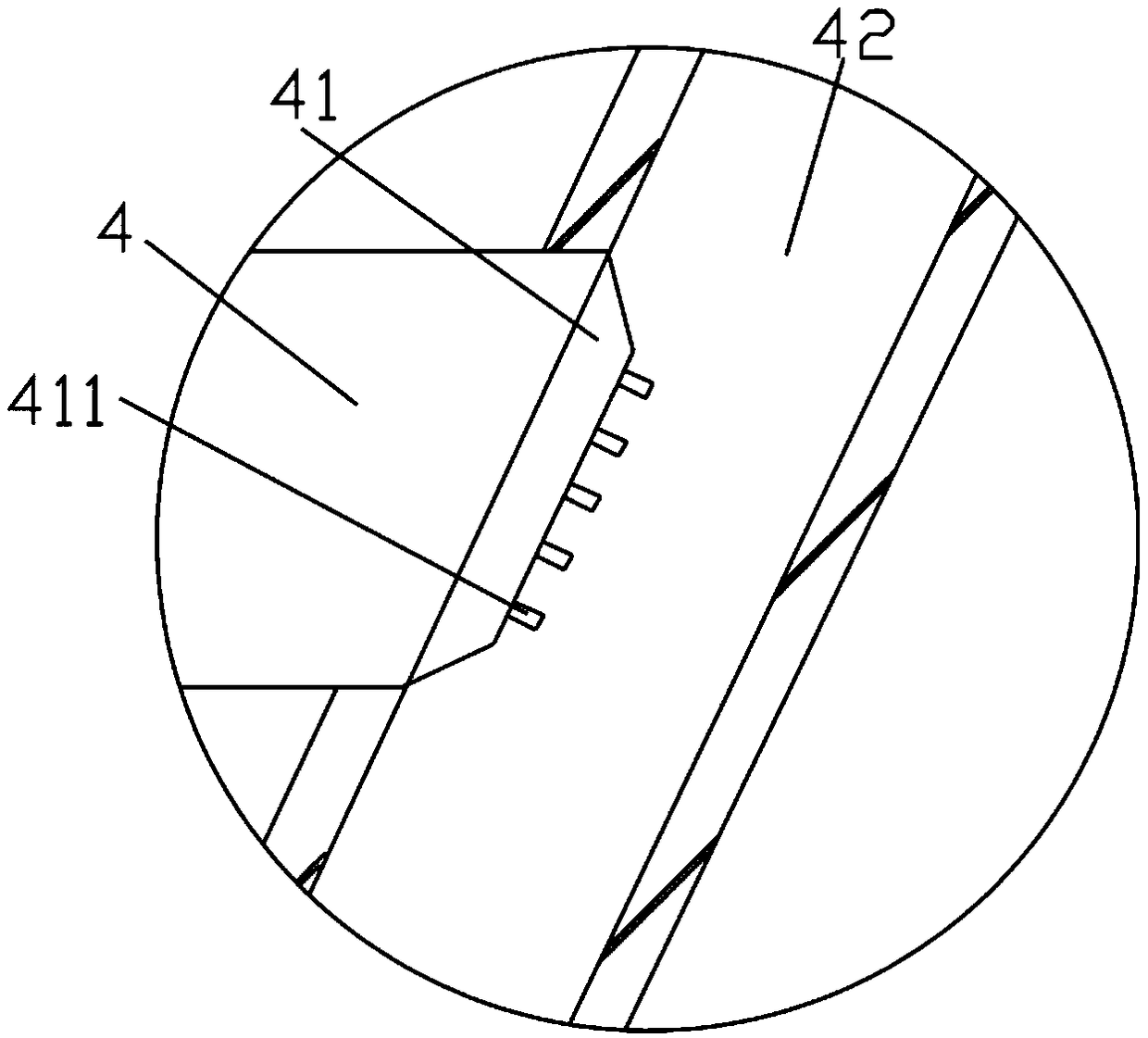

[0019] Described agitating mechanism comprises stirring drum 2, is located at the rotating shaft 22 in stirring drum 2 and a plurality of rotating plates 23, and described a plurality of rotating plates 23 is equidistantly arranged on the outer circumferential surface of rotating shaft 22, and described stirring drum 3 tubes The wall is grid-like, and the mesh can only accommodate dust passing through. The rotating plate 23 is hollow, and the side of the rotating shaft 22 is connected to the motor 25. The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com