Anti-dragging charging gun

A charging gun and anti-trag technology, applied in electric vehicle charging technology, circuits, electric vehicles, etc., can solve problems such as detachment, and achieve the effect of improving reliability, preventing human theft or malicious damage, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

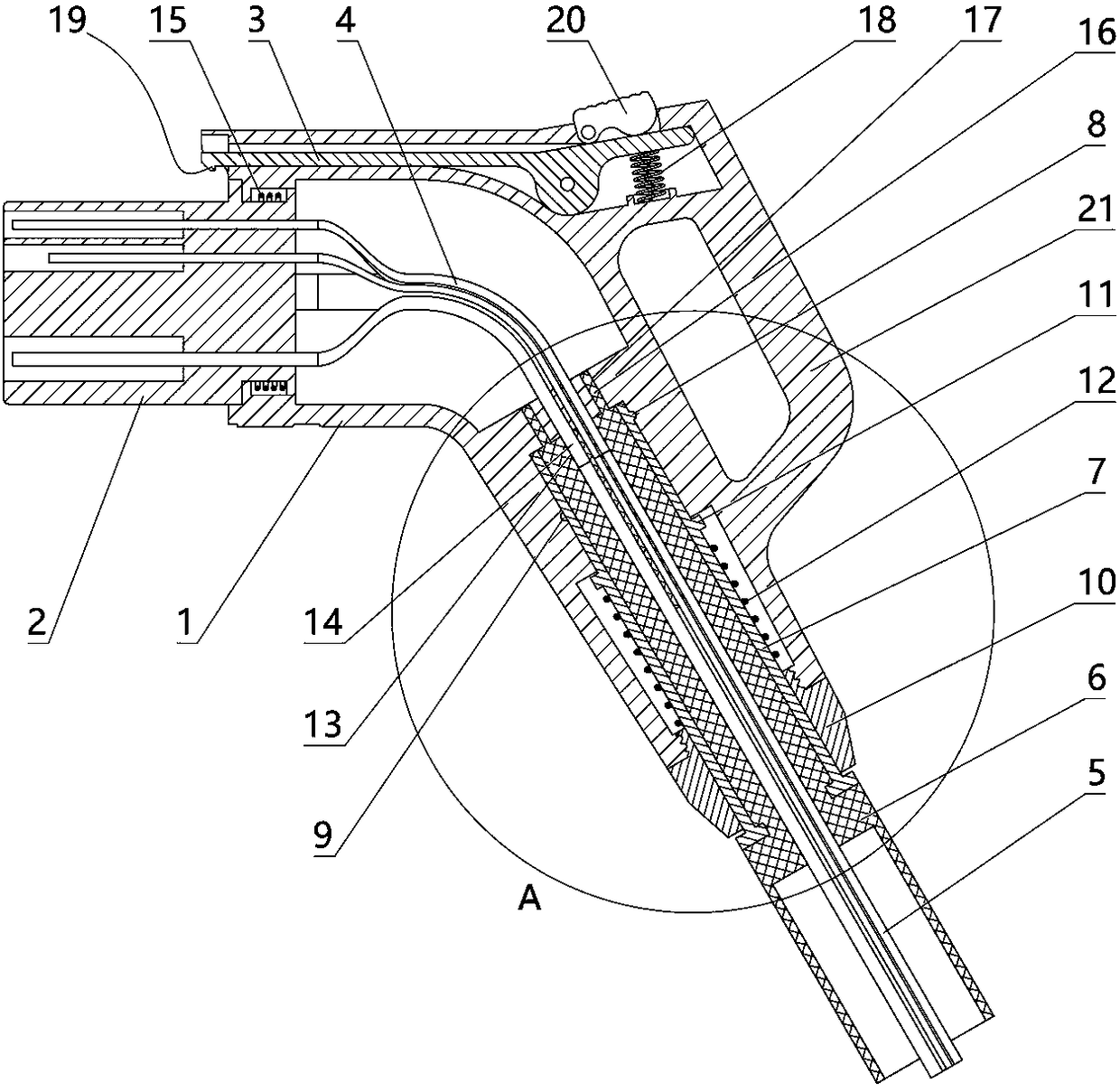

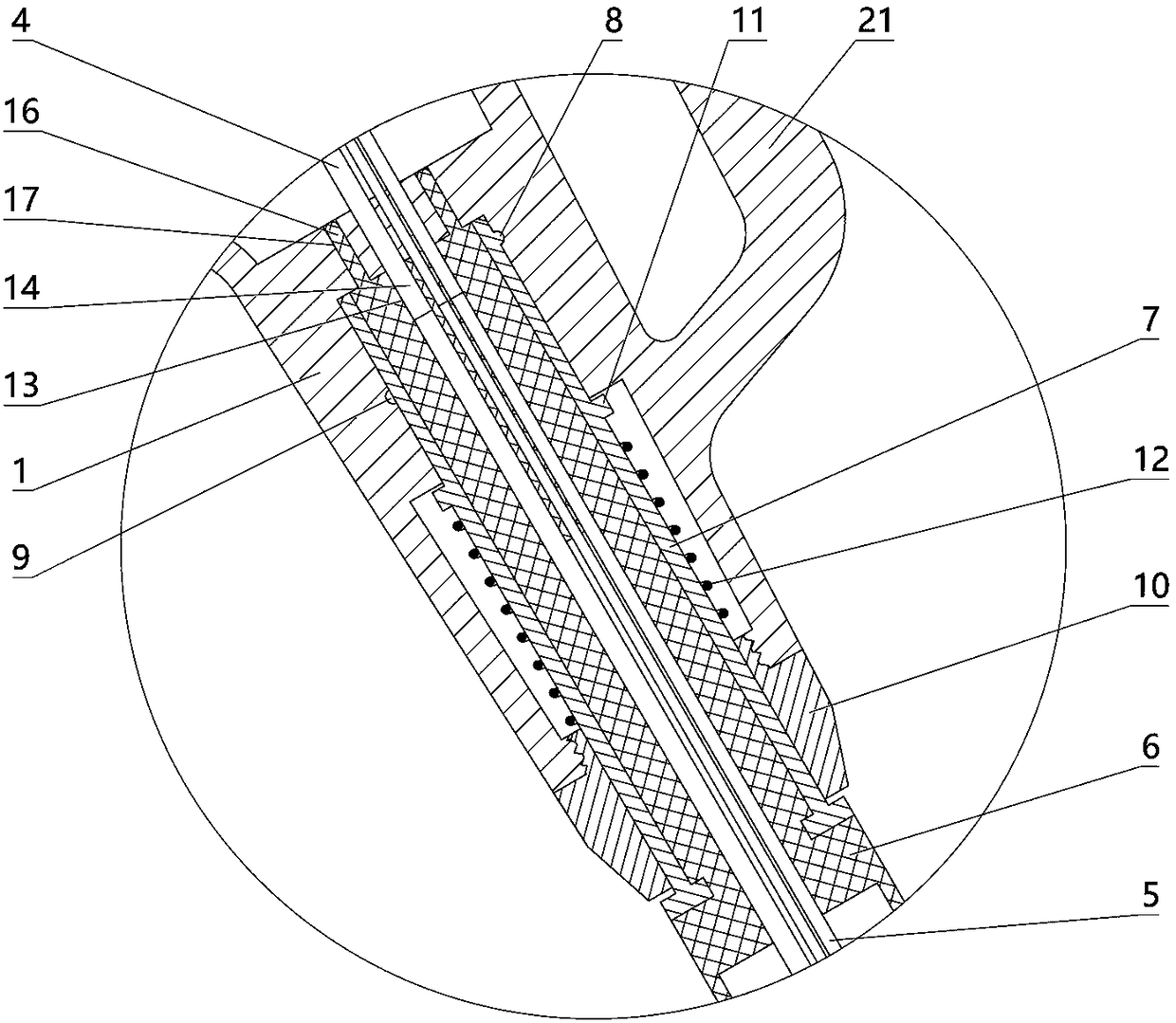

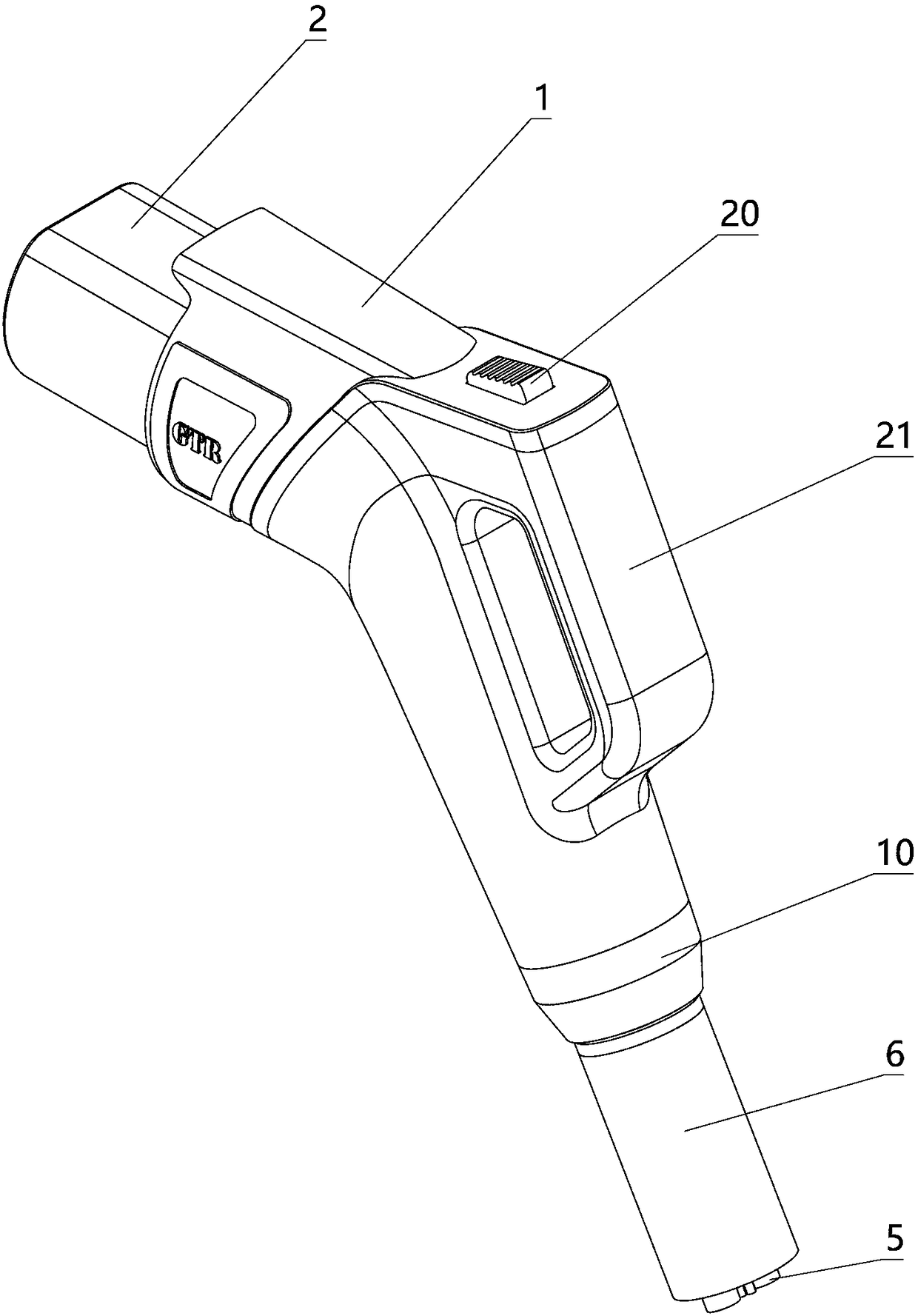

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Depend on Figure 1 to Figure 5 Given, the present invention includes a gun body 1 with an inner cavity, a plug 2 installed at the left end of the gun body 1, a locking member 3 installed on the upper part of the gun body 1, a wire harness 4 and a cable 5, and a socket sleeve 6 A rotatable sleeve 7 that is consistent with the length direction of the socket sleeve 6 is set on the socket sleeve 6, and the end of the sleeve 7 close to the inner cavity has a push rod 8 arranged radially along the rotation axis of the sleeve 7, and the gun The body 1 has a cam groove 9 spirally arranged along the rotation axis of the sleeve 7 and matched with the push rod 8, and the push rod 8 is placed in the cam groove 9. When the sleeve 6 moves in the length direction, under the transmission and guidance of the push rod 8 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com