Optical casing having a reduced weight for a motor vehicle, optical module, and vehicle body part

A technology of motor vehicles and optics, which is applied to vehicle components, components of lighting devices, optical signals, etc., and can solve the problems of limited accessibility of functional components and disassembly of optical modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

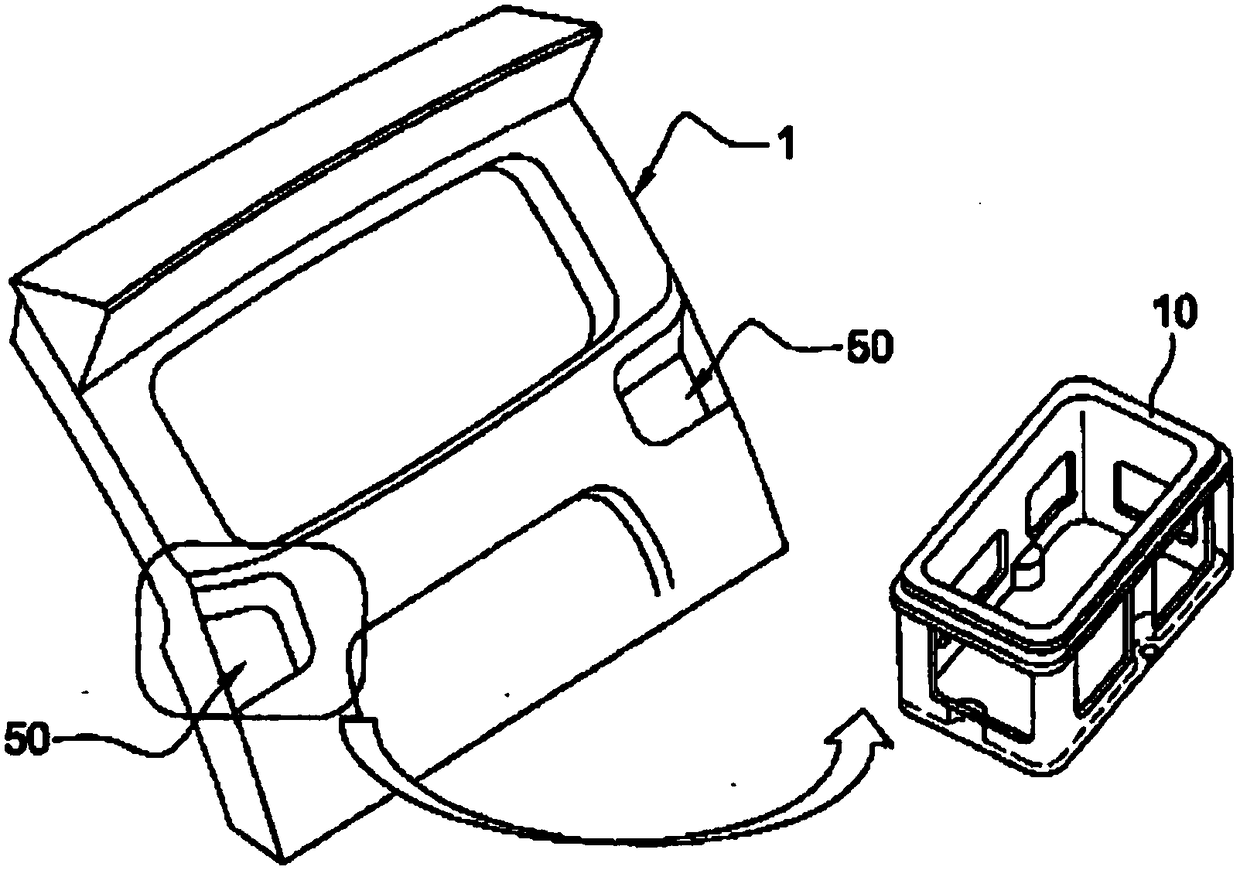

[0033] now refer to figure 1 , which shows an example of a motor vehicle component 1, which is a tailgate, which includes a receiving space 50 suitable for receiving an optical box 10 according to the present invention.

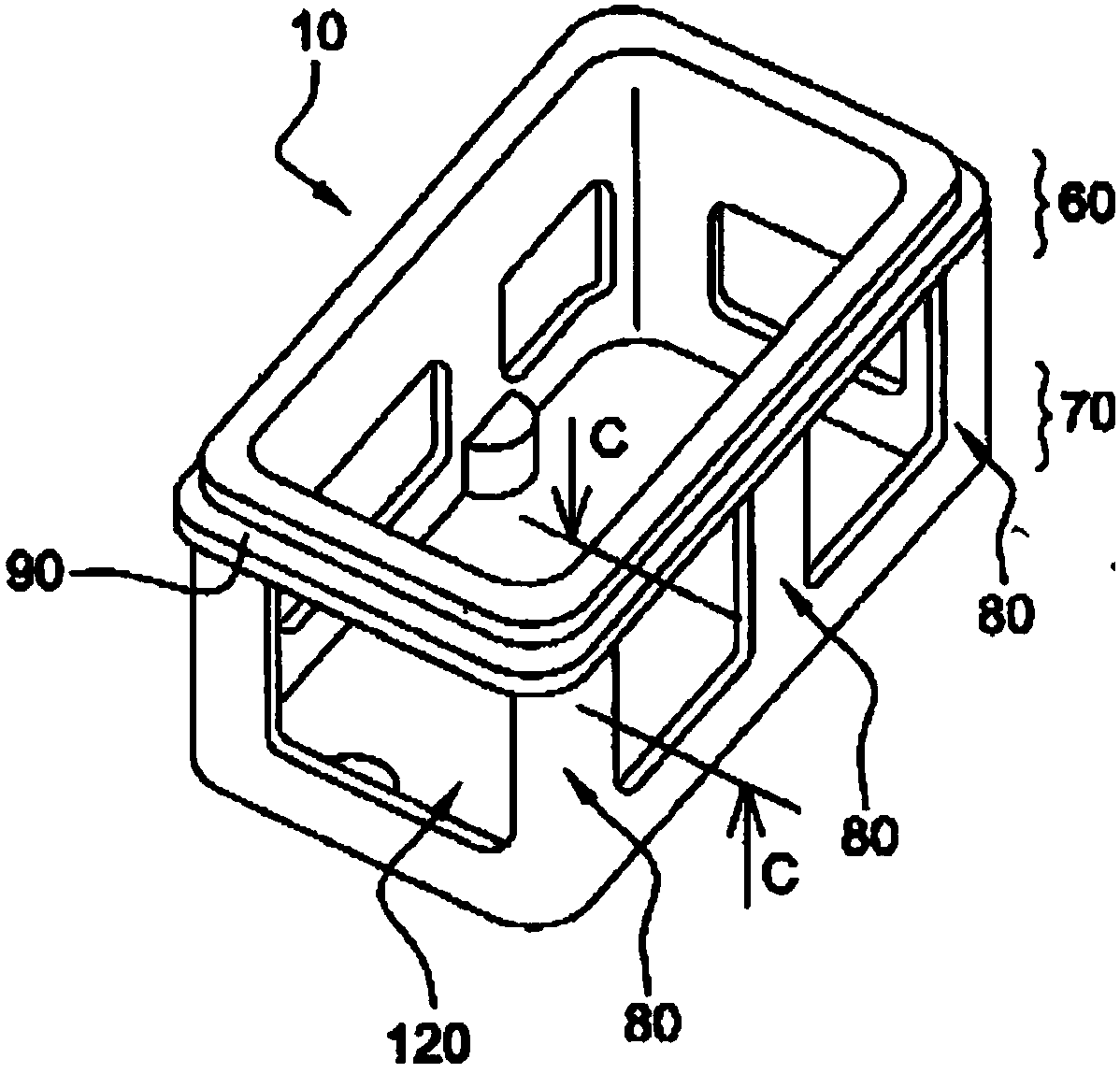

[0034] Figure 2A and Figure 2B A specific embodiment of an optical housing 10 for a motor vehicle according to the invention is shown in more detail.

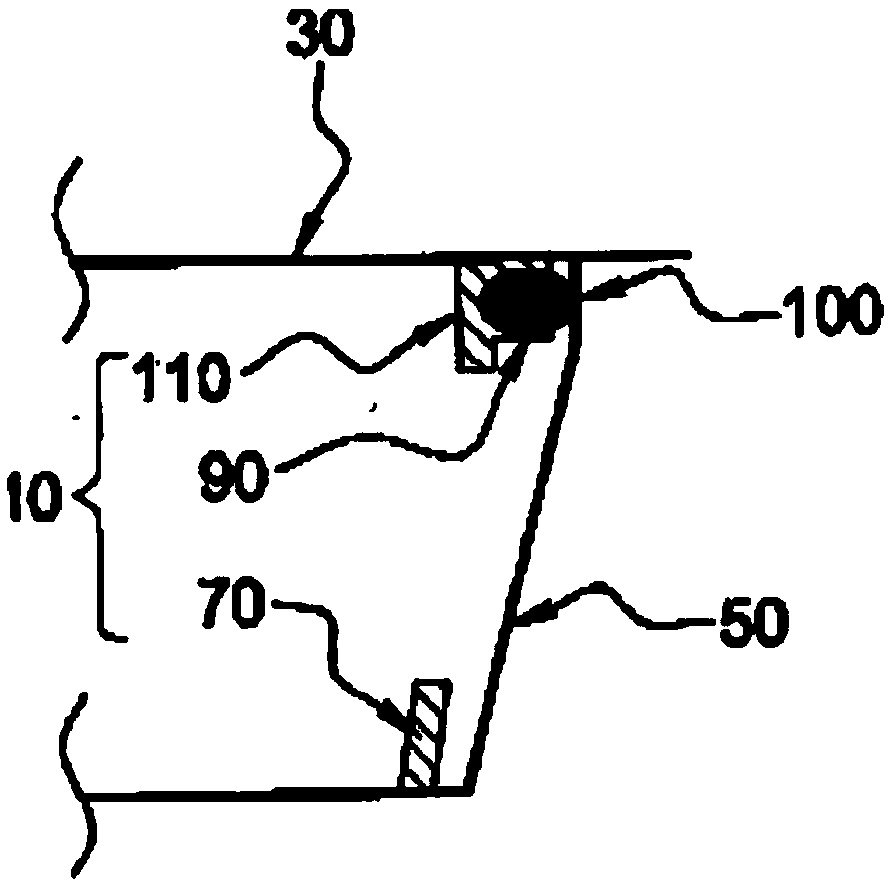

[0035] Figure 2A The optical box 10 is shown in three dimensions, and Figure 2B It is a sectional view along CC of a part of the optical box 10 with its glass 30 and its accommodating space 50 .

[0036] The optical box 10 is adapted to receive functional components 20 (electrical, electronic and optical) and to be closed by glass 30 to constitute an optical module 40 .

[0037] The optical module 40 is intended to be fastened in a receiving space 50 of the motor vehicle provided for this purpose.

[0038] The optical box 10 comprises an upper part 60 for receiving glass: this part is thus arranged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com