Anti-odor thermal insulation pigsty

A pig house and heat preservation technology, which is applied in animal houses, applications, animal husbandry, etc., can solve the problems of untimely cleaning and discharge of manure, underutilization of pig manure, and high heating costs for pig houses, so as to reduce Chance of contracting disease, damage reduction, comfortable reproduction and effects of growing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

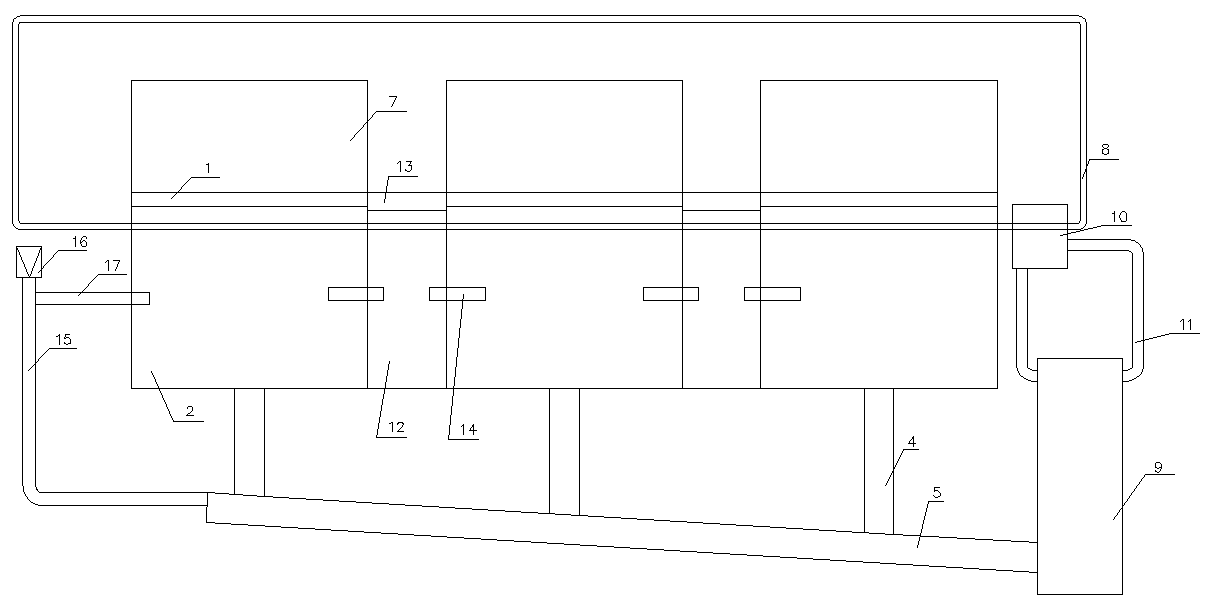

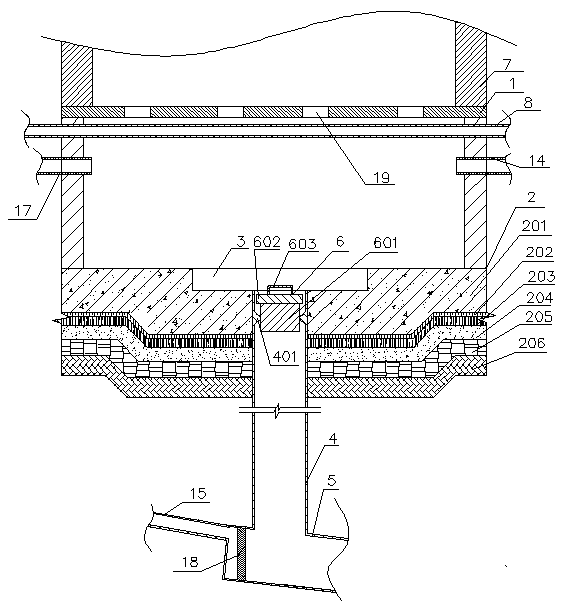

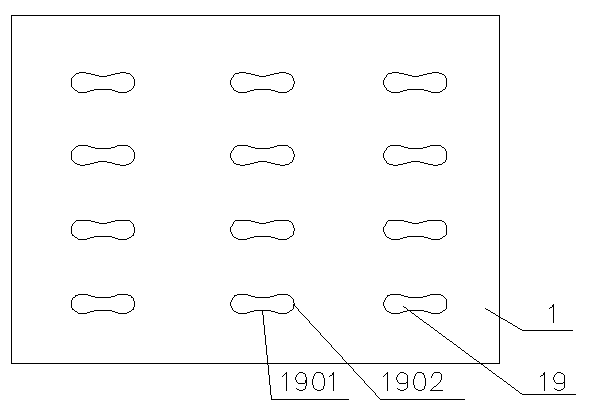

[0022] Such as Figures 1 to 3 As shown, a deodorant-type thermal insulation pig house includes a feces storage room 9, a heat pump 10, and a plurality of pig house bodies 7 surrounded by a dung leaking board 1 and walls arranged around the dung leaking board 1, and the dung leaking board 1 is provided with a floor heating pipe 8 which supplies heat to the pig house body 7, and a septic tank 2 is provided below the floor heating pipe 8.

[0023] The septic tank 2 is surrounded by the bottom wall of the pool and the side walls of the pool arranged around the bottom wall of the pool. Two adjacent septic tanks 2 are respectively located on the same plane. The upper opposite pool side walls extend in the direction and form a ventilation chamber 12 for allowing the gas in two adjacent septic tanks 2 to communicate.

[0024] The top of the air chamber 12 is sealed by a concrete cover plate 13, and an air pipe 14 is arranged in the air chamber 12. One port of the air pipe 14 communi...

Embodiment 2

[0033] Such as Figures 1 to 3 As shown, a deodorant-type thermal insulation pig house includes a feces storage room 9, a heat pump 10, and a plurality of pig house bodies 7 surrounded by a dung leaking board 1 and walls arranged around the dung leaking board 1, and the dung leaking board 1 is provided with a floor heating pipe 8 which supplies heat to the pig house body 7, and a septic tank 2 is provided below the floor heating pipe 8.

[0034] The septic tank 2 is surrounded by the bottom wall of the pool and the side walls of the pool arranged around the bottom wall of the pool. Two adjacent septic tanks 2 are respectively located on the same plane. The upper opposite pool side walls extend in the direction and form a ventilation chamber 12 for allowing the gas in two adjacent septic tanks 2 to communicate.

[0035] The top of the air chamber 12 is sealed by a concrete cover plate 13, and an air pipe 14 is arranged in the air chamber 12. One port of the air pipe 14 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com