Boring method for machining hole system of crossing angle box body

A box and hole system technology, applied in the field of corner box processing and manufacturing, can solve the problems of limited machine tool selection and inability to process ordinary boring machines, and achieve the effect of increased machine selection range, good use effect, and low rotation accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

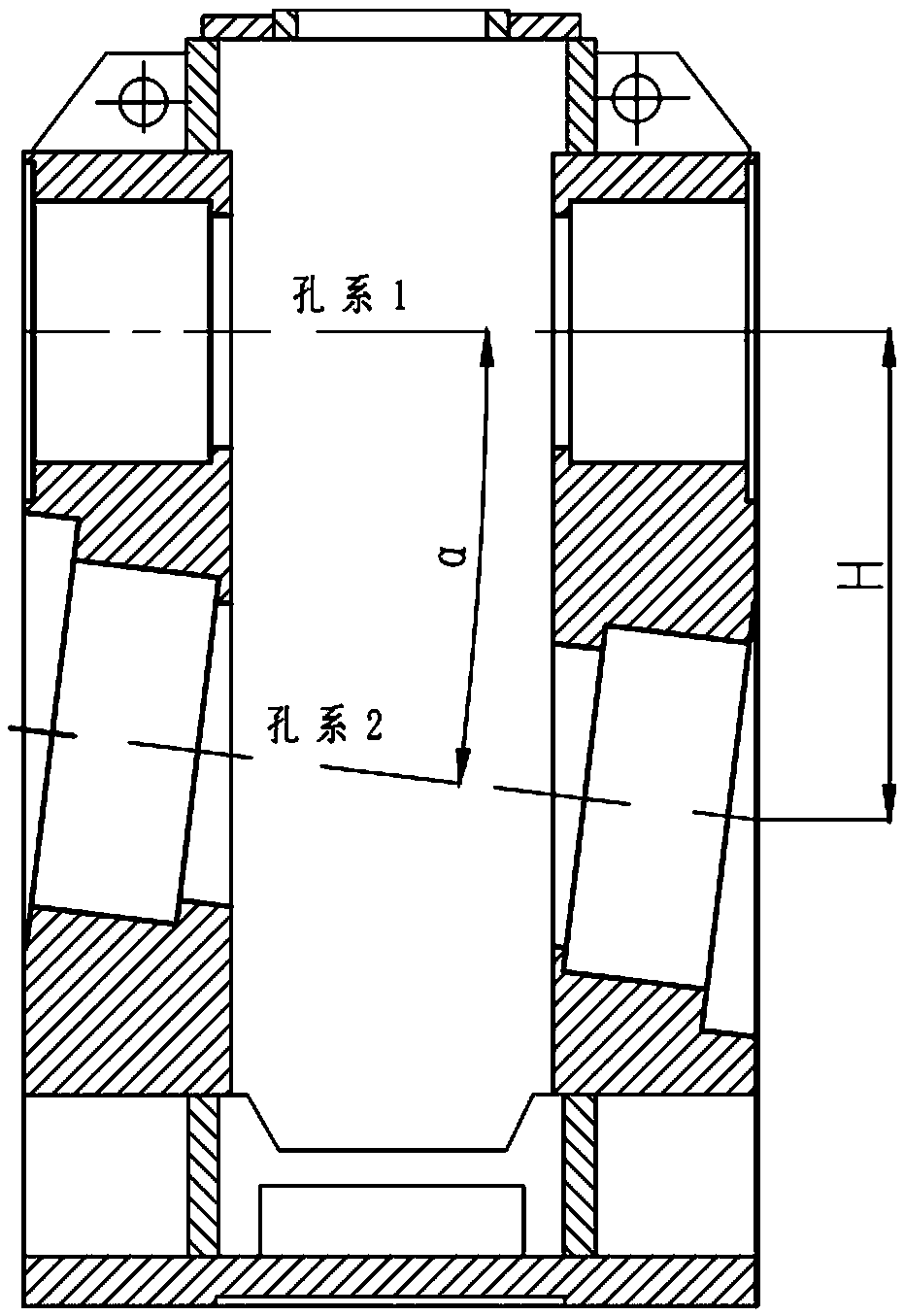

[0030] Example: Take the processing of a certain type of corner box as an example, the parameters are: angle 7°±20", the center distance from the big end is 503.48±0.02, and the material is Q235 steel; the implementation steps are as follows:

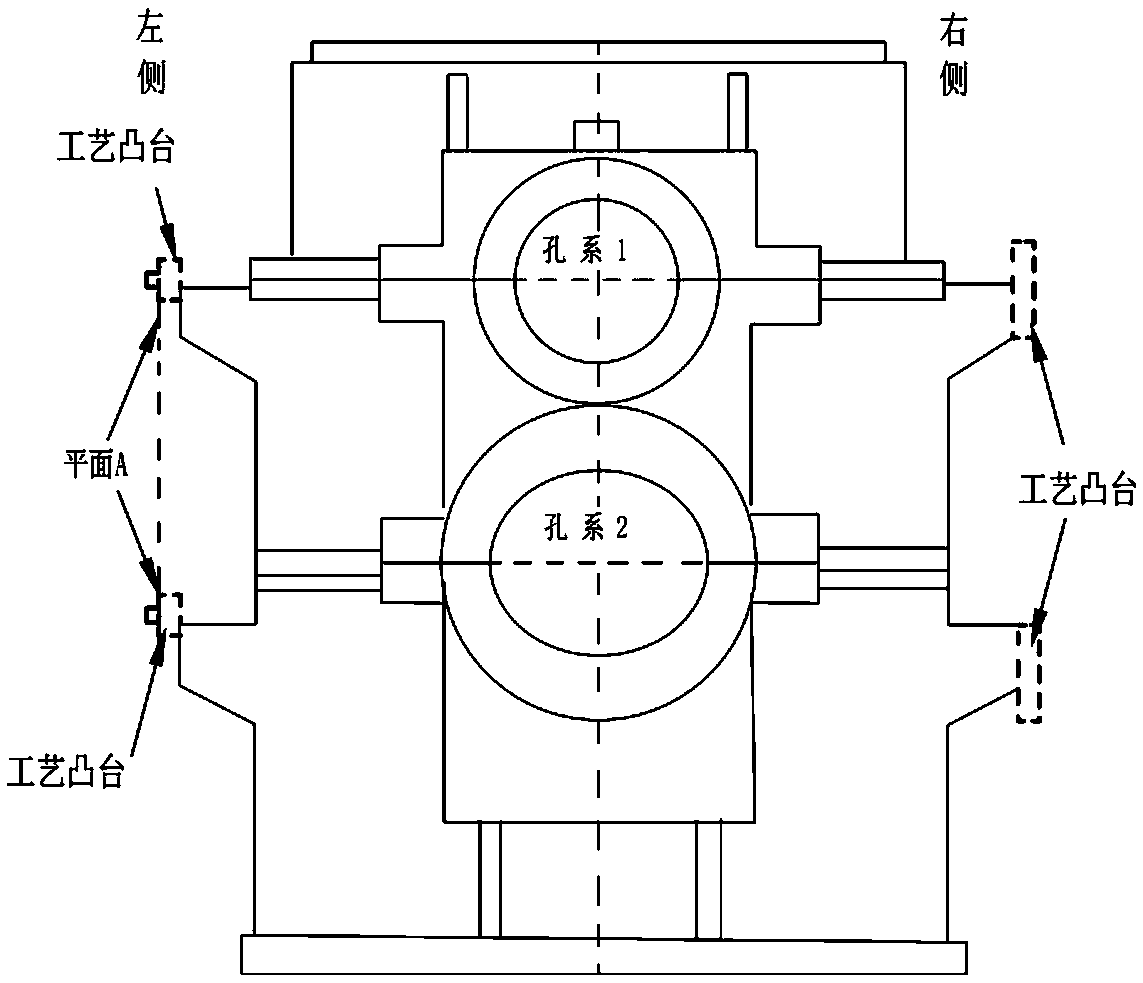

[0031] 1) Communicate with the blank manufacturer to increase the process bosses on the left and right sides, the left side is used for processing pin holes, and the right side is used for parts clamping, such as Figure 10 shown. (This step is implemented in conjunction with the part structure)

[0032] 2) On the left side of the box, process the 4-φ16H7 positioning pin hole and the plane where the pin hole is located according to the hole system requirements of the part drawing and the CAD drawing conversion size, and install 4 pieces of GB119 16X30 cylindrical pins, such as Figure 11 shown.

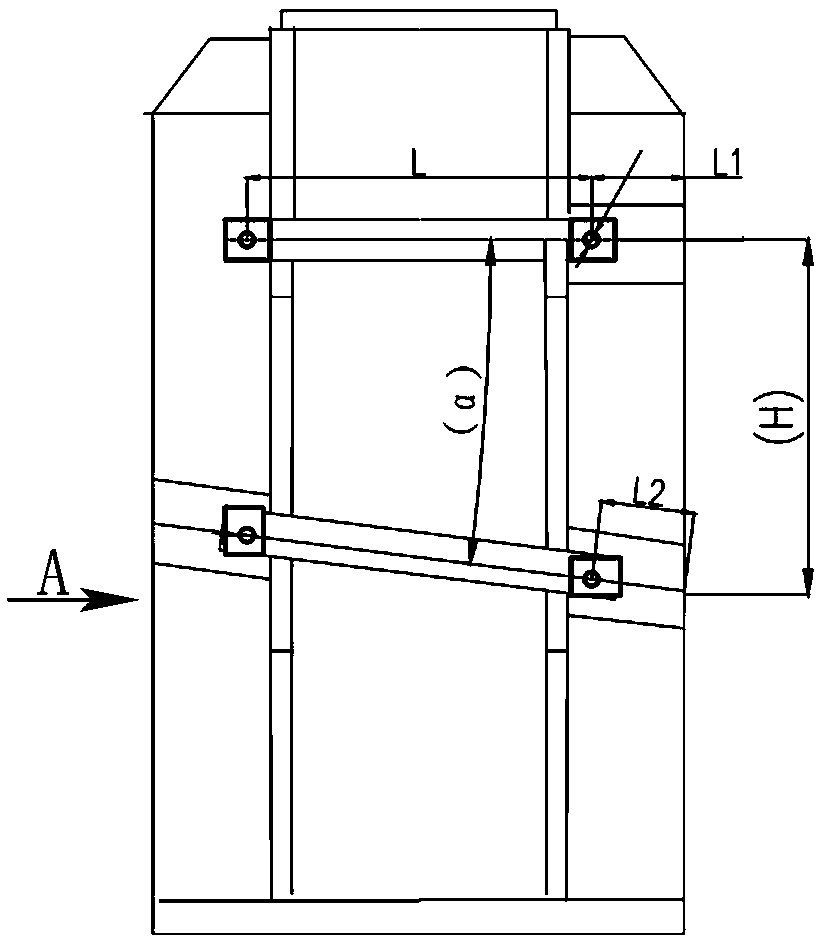

[0033] 3) Put the positioning pin end of the box upwards, press Figure 4 Clamping at the processing position, first align the set of posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com