Automatic welding back gas protection tool

A gas shielded, automatic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to apply automatic welding speed, increase workload and labor cost, and reduce the quality of weld protection. Achieve the effect of small occupied space, simple structure and saving installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

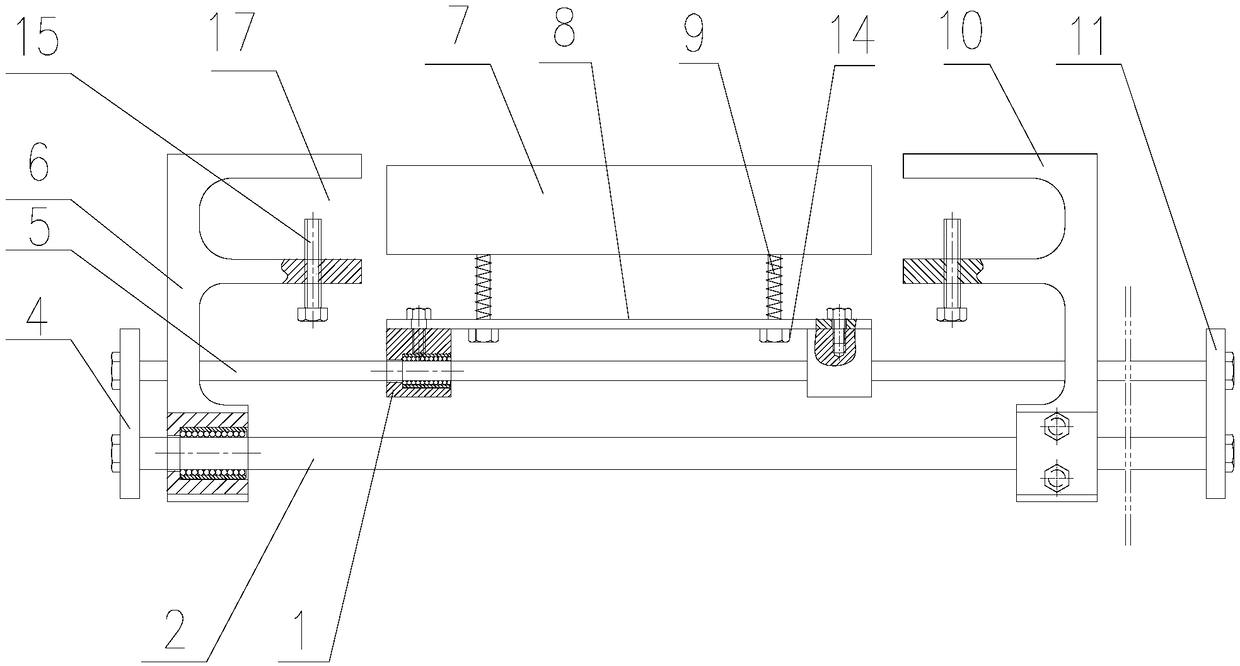

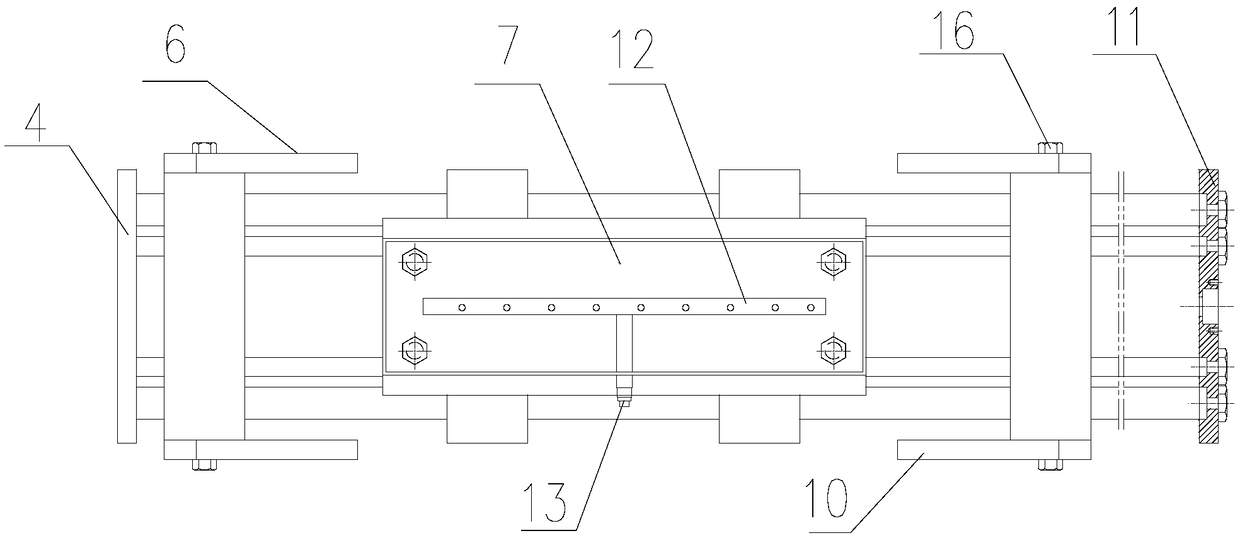

[0014] figure 1 Among them, including the protective cover slider 1, the first guide rail 2, the left cover plate 4, the second guide rail 5, the left clamp plate 6, the protective cover 7, the installation plate 8, the spring 9, the right clamp plate 10, the right cover plate 11, Air duct 12, air inlet 13, connecting bolt 14, fastening bolt 15, fixing bolt 16, clamping part 17, etc.

[0015] like figure 1 As shown, an automatic welding back gas protection tool of the present invention includes a left cover 4 and a right cover 11, a first guide rail 2 and a second guide rail 5 are arranged between the left cover 4 and the right cover 11, and the first guide rail 2. Under the second guide rail 5, the left clamping plate 6 is slidably arranged on the first guide rail 2 and the second guide rail 5 through linear bearings, and the left clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com