Double-sided synchronous placing device for saw chain assembly machine

A technology for assembling machines and decorations, which is applied to knives of sawing machines, assembling machines, metal sawing equipment, etc. It can solve problems such as low efficiency, inability to effectively connect B-side riveting, and inability to turn over automatically, so as to improve efficiency and save time , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

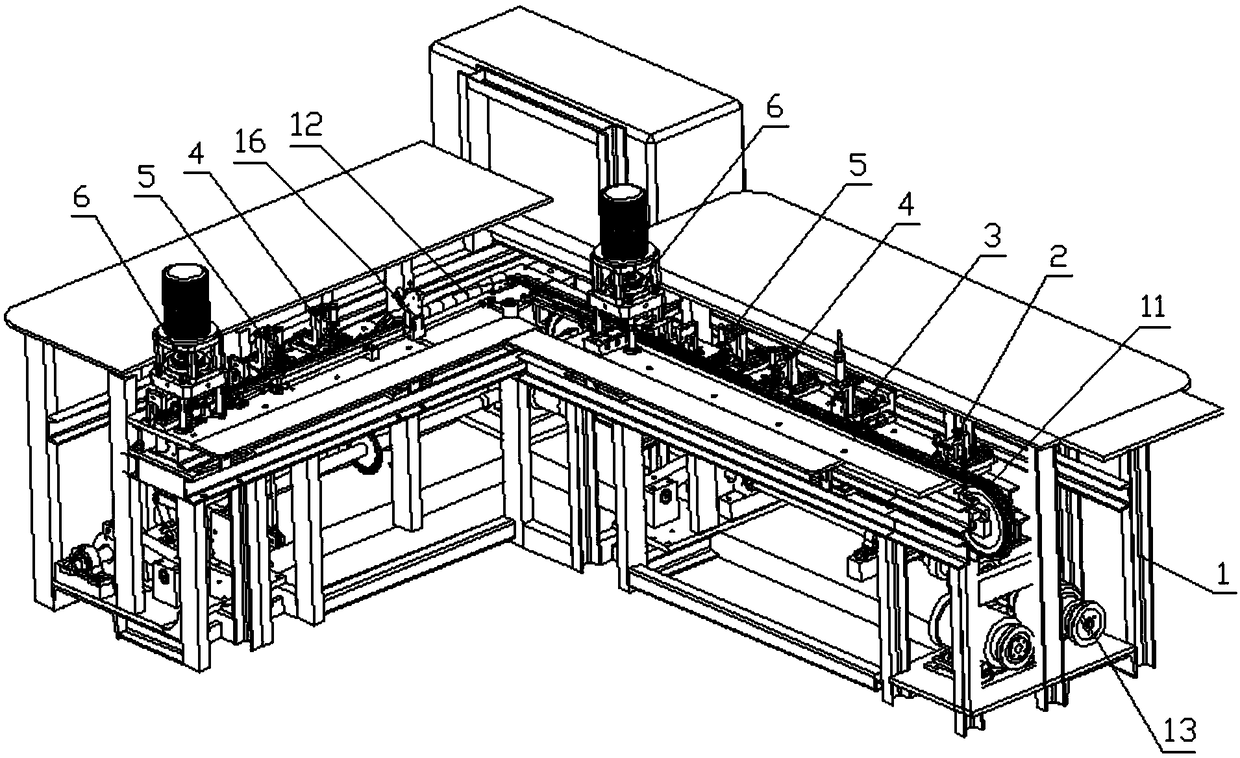

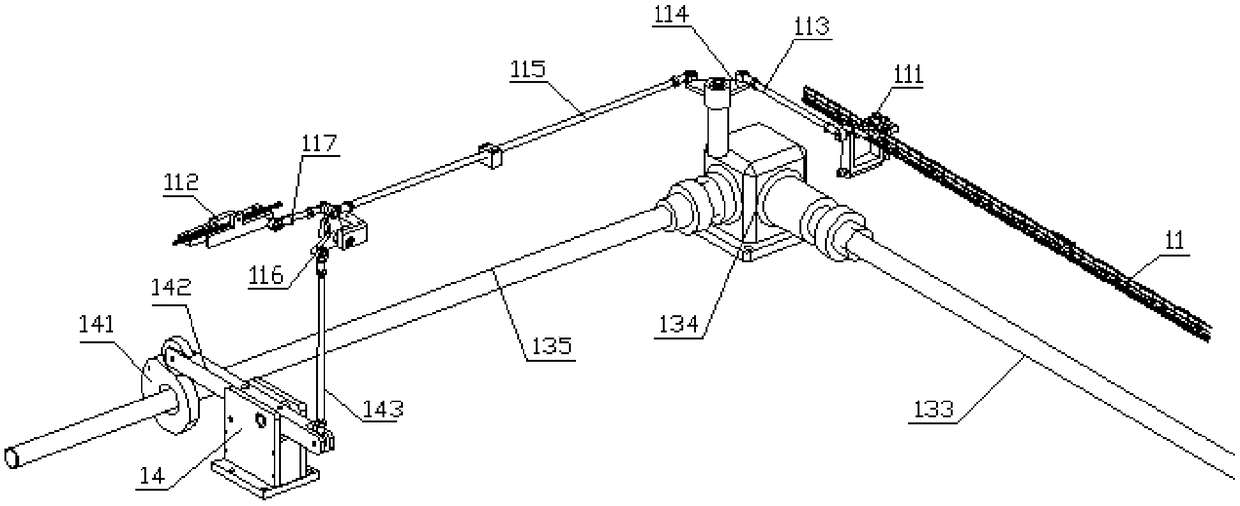

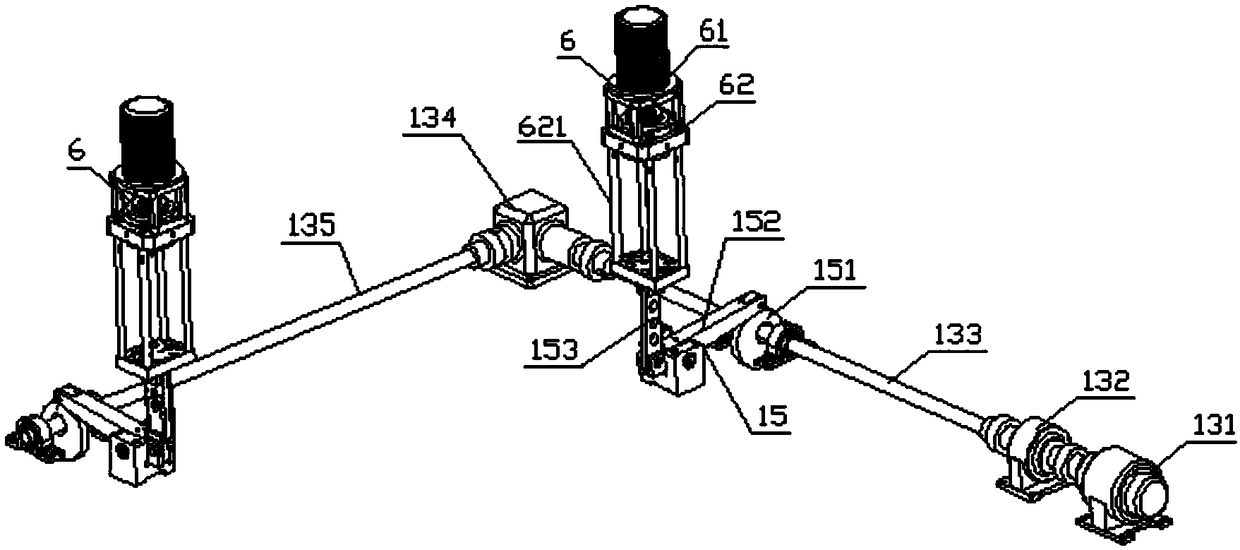

[0030] Embodiment 1, a saw chain automatic assembly machine, including a frame 1, a tank chain conveying mechanism 11 arranged on the frame 1, the tank chain conveying mechanism 11 has a horizontal transmission part located on the working table of the frame, the The horizontal transmission section includes a first horizontal transmission section and a second horizontal transmission section. Of course, with the operation of the tank chain conveying mechanism 11, the horizontal transmission section is also changing, and the first horizontal transmission section and the second horizontal transmission section are also changing. In this embodiment, viewed from the horizontal projection, the transmission directions of the first horizontal transmission section and the second horizontal transmission section are perpendicular to each other and form an L shape. The L-shaped arrangement can save length and space, and greatly reduce the walking distance of the operator. Those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com