Clearance adjusting device and method of mouth mold and core mold

A technology of gap adjustment device and die, which is applied in applications, household appliances, other household appliances, etc., can solve the problems of low adjustment efficiency, high labor cost, and inevitable replacement, so as to save labor cost, adjust efficiency, and Effect of reducing pipe waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

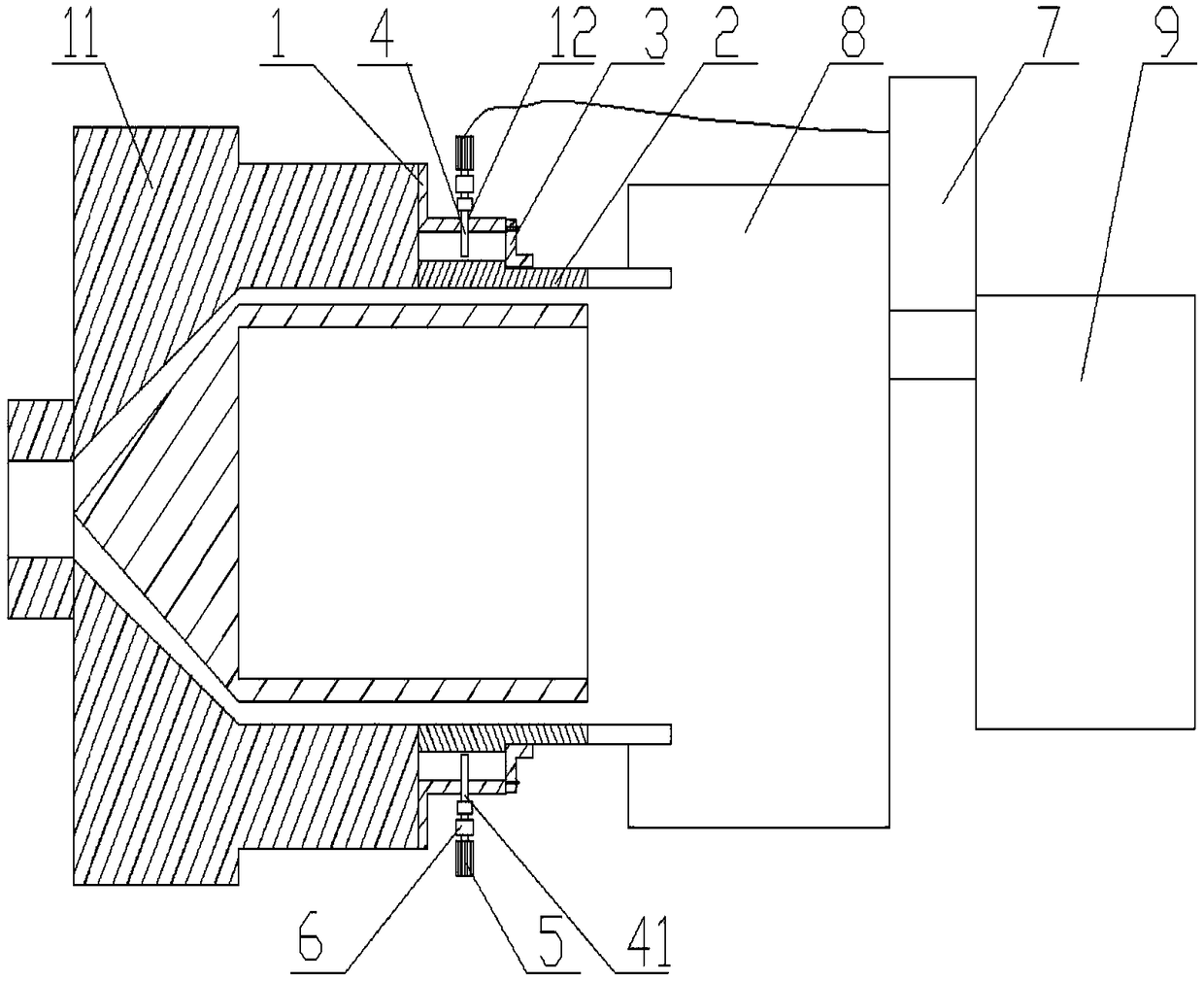

[0021] Embodiment 1, with reference to figure 1 , figure 2 , a gap adjustment device between a die and a mandrel, comprising a die adjusting and fixing seat 1, a die 2, a die pressing plate 3, an adjusting screw 4, the adjusting and fixing seat 1 of the die is cylindrical, and the die is One side of the adjusting and fixing seat 1 is fixedly connected to the extruder head body 11, the other side of the die adjusting and fixing seat 1 is detachably connected with the ring-shaped die pressing plate 3, and the die 2 is sleeved on the In the annular die pressing plate 3, the die 2 is in clearance fit with the annular die pressing plate 3, and the die adjustment fixing seat 1 is uniformly provided with 4 screw through holes 12 along the circumferential direction. , the screw through hole 12 is internally threaded with an adjusting screw 4 .

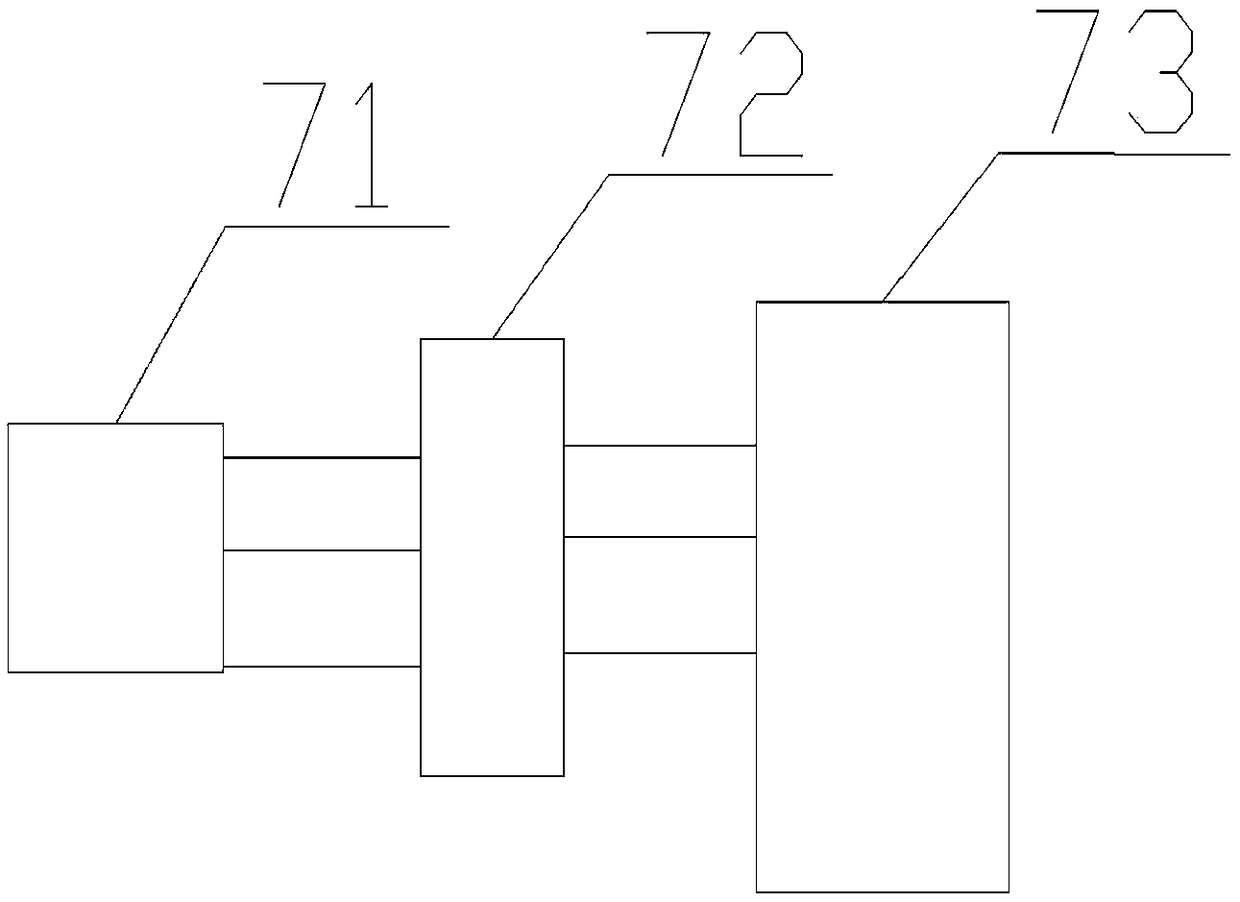

[0022] The four adjusting screws 4 are all connected and driven by a stepper motor 5 through a reducer 6, and the stepper motor 5 is elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com