Slitting equipment and tracing guiding device thereof

A guiding device and guiding technology, used in transportation and packaging, coiling strips, thin material processing, etc., can solve the problems of pole tab folding, inability to guide the pole piece, and inability to guide the pole tab, etc., to overcome the quality Problems, Overcoming the Effect of Folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of this specification.

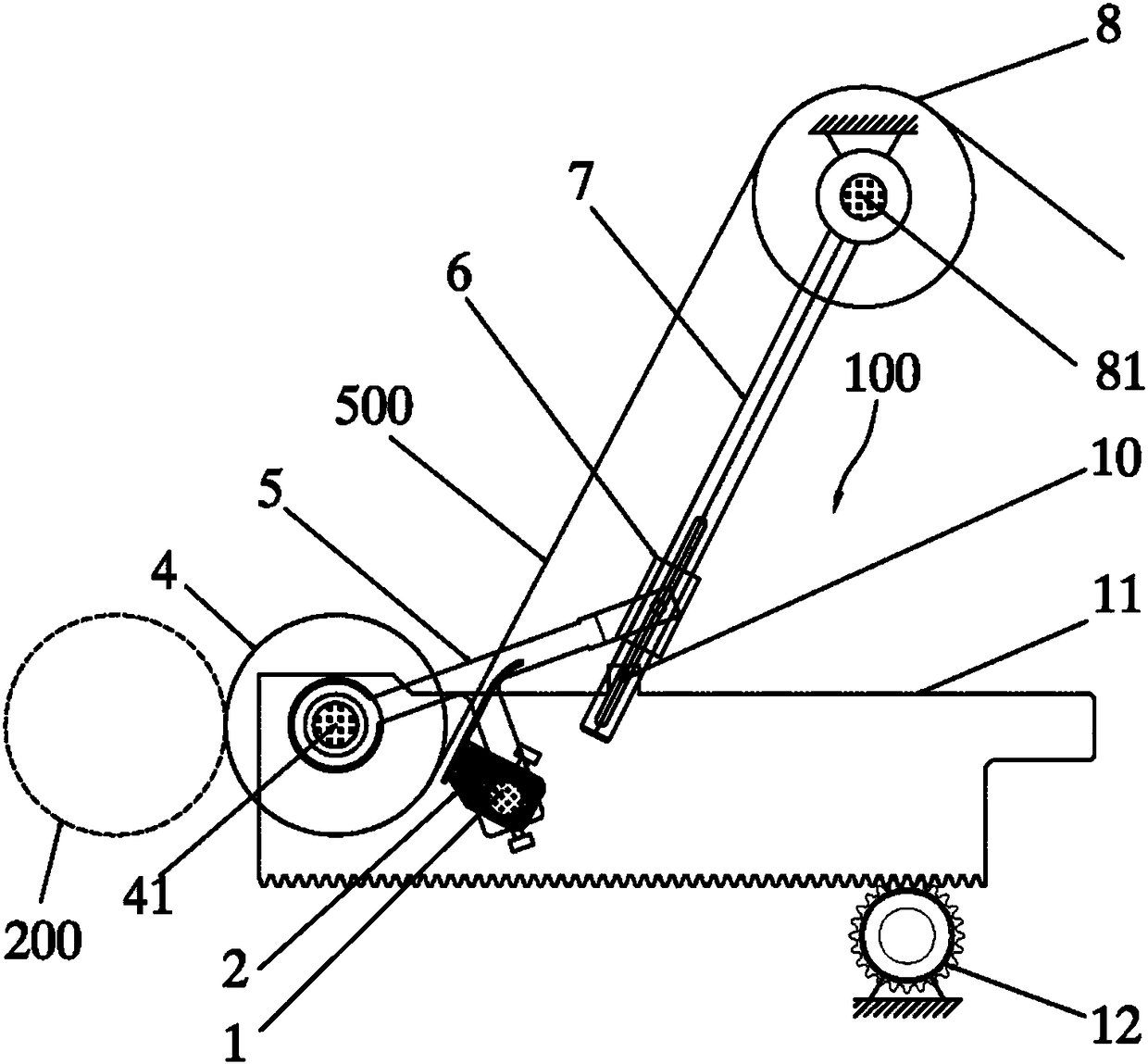

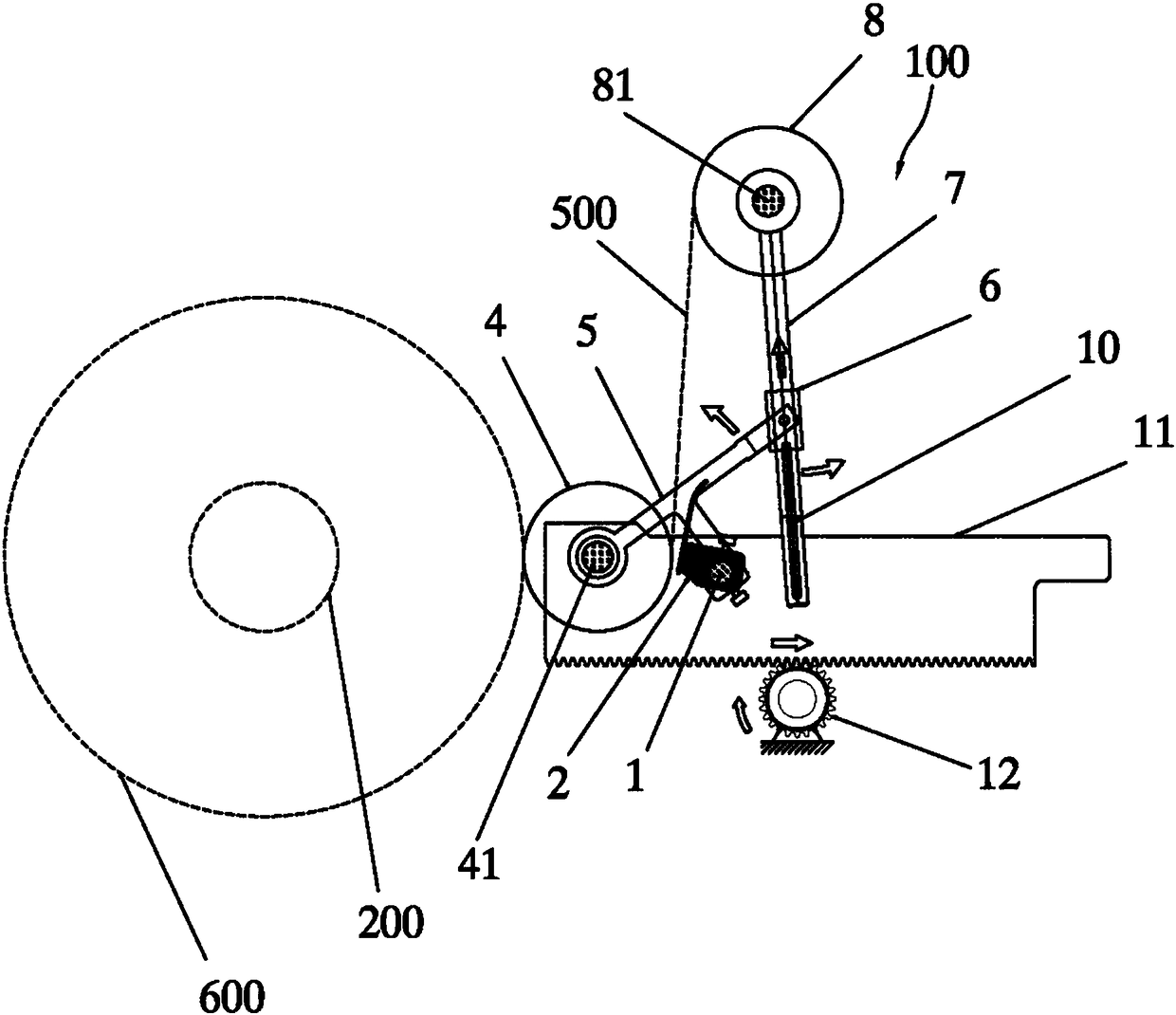

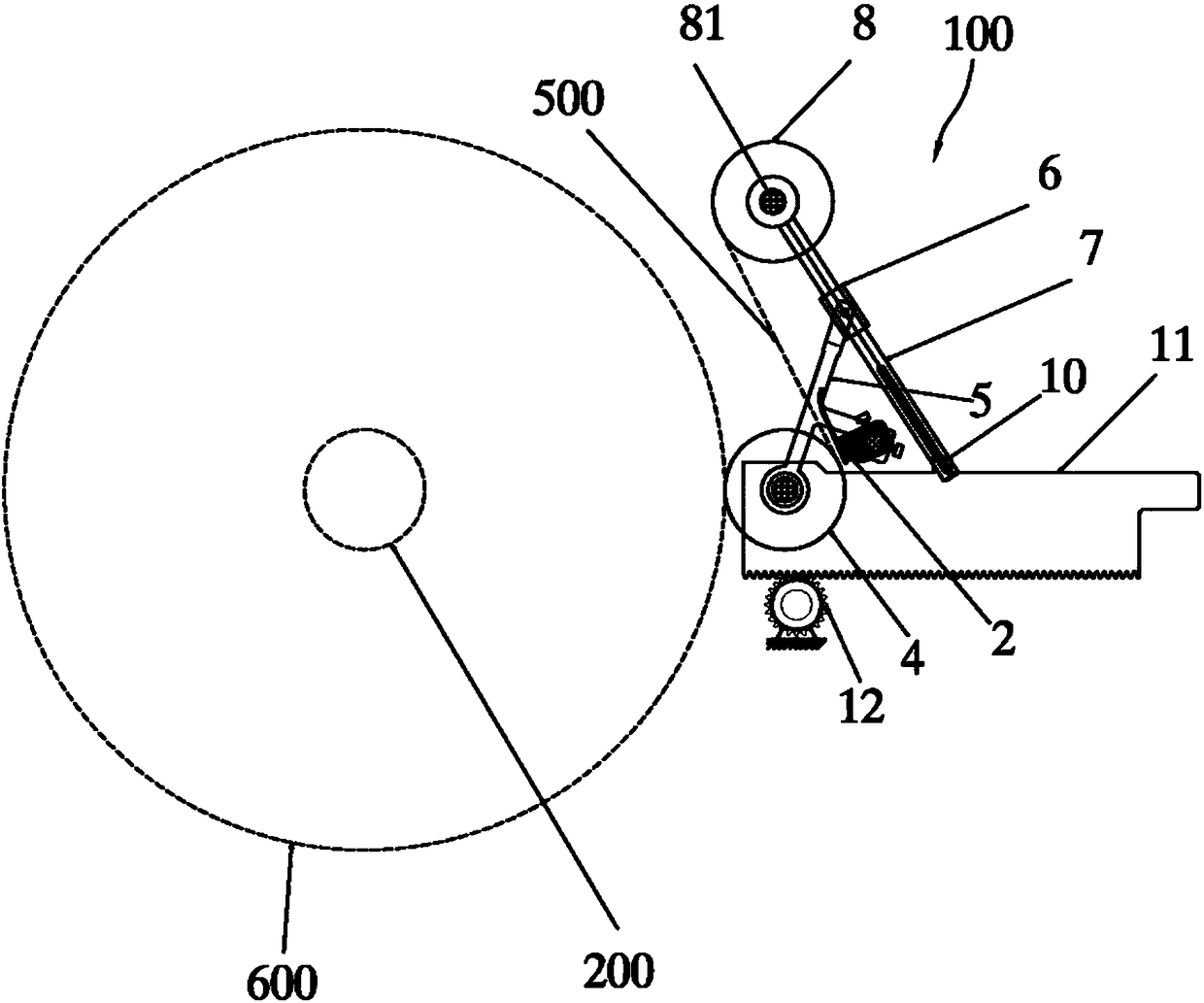

[0015] see Figure 1 to Figure 3 , figure 1 Indicating that the tracking journey is in the beginning state, figure 2 Indicates that the tracking stroke is halfway through, image 3 Indicates that the tracking trip is complete. The present invention proposes a slitting device, which generally includes: a tracking guide device 100 and a winding slip shaft 200, capable of slitting, guiding, and rewinding a foil material 500 with tabs to obtain Material volume 600.

[0016] The tracking and guiding device 100 specifically includes: an installation shaft 1, a pole piece guide frame 2, a tracking roller 4, a pole piece swing connecting rod 5, a sliding sleeve 6, a guide swing rod 7, a passing roller 8, a guide sliding pin 10, and a transmission rack 11 and tracking drive gear 12.

[0017] The pole piece swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com