An automatically controlled electrospinning system for large-area nanofibrous membrane preparation

A nanofiber membrane and electrospinning technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of high price and single form, so as to improve service life, stabilize environmental conditions and prevent impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

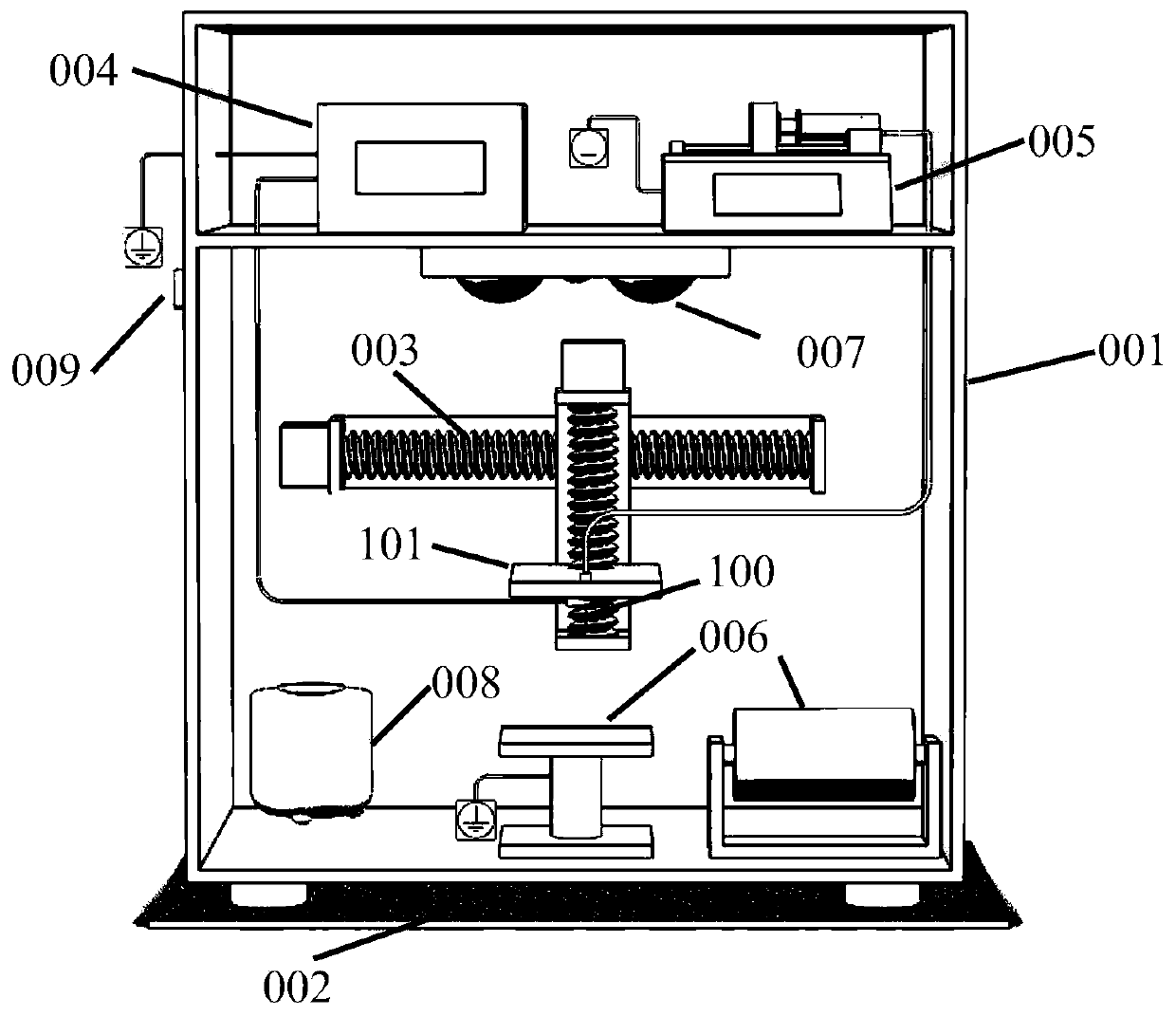

[0026] Such as figure 1 As shown, the present invention is used in a low-cost, high-stability automatic control electrospinning system for preparing nanofiber membranes in a large area. Installed on six sides of the device cabinet as the second panel, the entire device cabinet is placed on an insulating floor mat with anti-skid function. The spinning needle driving device is fixed on the rear polymer panel at a certain height from the first floor of the device cabinet, which includes a horizontal driving device and a vertical driving device, and the horizontal driving device is used to realize the horizontal movement of the spinning needle to achieve a large area The purpose of the preparation of the nanofiber membrane, the vertical transmission device is used to realize the vertical movement of the spinning needle, and complete the adjustment of the height between the spinning needle and the receiving device before spinning; both the horizontal and vertical transmission devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com