An integral multi-way valve for garbage compression control and its control method

A garbage compression, integrated technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of affecting the reliability and service life of the system and its components, affecting the production and processing efficiency of products, and increasing the number of system valve blocks Problems such as production and processing, to achieve the effect of simplifying the garbage compression control system, improving the performance of the product, reducing the number of system components and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

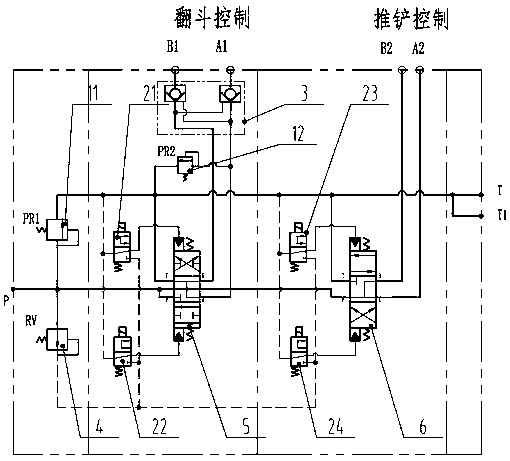

[0028] Reference attached figure 1 , the integrated multi-way valve for garbage compression control of the present invention includes overflow valves 11, 12, two-position three-way solenoid valves 21, 22, 23, 24, hydraulic lock assembly 3, pressure reducing valve 4, and turning motion control assembly 5. The shovel motion control assembly 6 and P, A1, B1, A2, B2, oil ports; the overflow valve 11 communicates with the P, T oil ports to control the safety pressure of the system; the overflow valve 12 is in The overturning movement controls the oil circuit, which limits the maximum load of the dumping bucket of the garbage compression box; the overturning movement control component 5 realizes the function of a 3-position 6-way hydraulic control reversing valve, and the first solenoid valve 21 and the second solenoid valve 22 respectively obtain In the case of electric power, the function of turning up and down the dumping bucket of the compression box is realized, and combined wi...

Embodiment 2

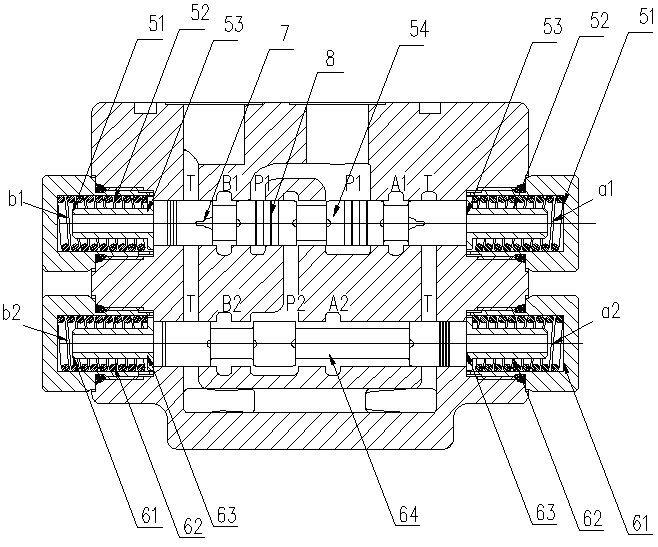

[0030] Reference attached figure 2 , the integrated multi-way valve for garbage compression control of the present invention, the overflow valve 1, the solenoid valve 2, the hydraulic lock assembly 3, the pressure reducing valve 4, the turning motion control assembly 5, and the shovel motion control assembly 6 are all integrated in the In an integrally cast valve body. The overturn motion control assembly 5 mainly includes A end cover 51, A return spring 52, A spring seat 53, overturn valve stem 54 and seals. This assembly cooperates with the cast valve body to form P1, P2, A1, B1, T-shaped Cavity, and spring control chamber a1, b1, wherein the spring control chamber communicates with the first solenoid valve 21, the second solenoid valve 22 working port, the flip valve stem 54 is in the first solenoid valve 21, the second solenoid valve 22 and the return spring Under the joint action, there are three stations, left, middle and right, corresponding to three cavity connection...

Embodiment 3

[0033]On the basis of Embodiment 2, buffer throttles and pressure equalization grooves are provided on the valve stems of the turning motion control assembly 5 and the push blade motion control assembly 6, so as to reduce the pressure shock neutralization during the reversing process and the reversing resistance; This form of electro-hydraulic pilot control greatly prolongs the reversing time and pressure drop gradient during the reversing process with the throttling and buffering of the main valve core opening, and greatly reduces the hydraulic shock during the reversing process. . The hydraulic lock assembly includes two hydraulically controlled check valves 31 and hydraulically controlled reversing valve rods 32, which are controlled in conjunction with the turning motion control assembly 5 to realize that the tipping bucket can stop at any point. Because the hydraulically controlled check valve 31 It is an integral cone valve structure, which can achieve zero leakage, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com