Rubber tire power frame for trackless guided tram and trackless guided tram

A power frame and rubber wheel technology, applied to vehicle components, steering mechanisms, steering mechanisms of front and rear tandem vehicles, etc., can solve problems such as difficult low-floor, no longer suitable, etc., shorten the manufacturing cycle, increase the carrying capacity, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

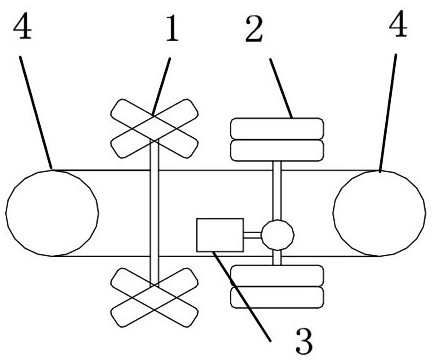

[0027] Embodiment 1: as figure 1 As shown, the rubber-tyred power frame for trackless guided trams of the present invention includes an active steering axle assembly 1, a power shaft assembly 2 with a biased power input port for dual-tire load or single-tire load, a drive motor 3 and two With hinge assembly 4, driving motor 3 is connected with final reducer and differential gear in the offset power input port, and angle sensor is installed at the upper joint point in hinge assembly 4 to measure the angle of hinge. Two hinge assemblies 4 are located at the two ends of the power frame, and are used to connect with two adjacent compartments of the trackless guided tram.

[0028] In this embodiment, an angle sensor is installed on the active steering axle assembly 1 on the bogie to detect the wheel deflection angle.

[0029] In this embodiment, all wheels are equipped with wheel speed sensors to detect the wheel speed.

Embodiment 2

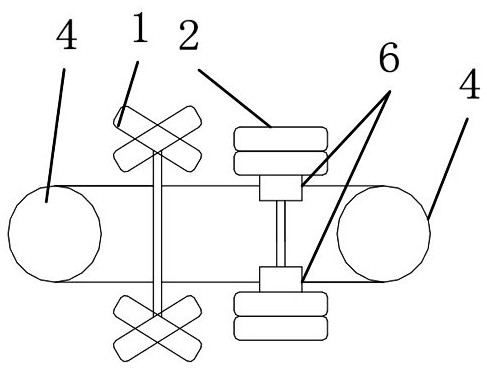

[0030] Embodiment 2: as figure 2 As shown, the rubber-tyred power frame for trackless guided trams of the present invention includes an active steering axle assembly 1, a power axle assembly 2 that adopts twin-tire bearing or single-tire bearing, wheel edge / hub motor 6 and two hinged assemblies 4. The wheel side / hub motor 6 is connected with the power shaft assembly 2 and drives the power shaft assembly 2 . An angle sensor is installed at the upper joint point in the hinge assembly 4 to measure the angle of the hinge. Two hinge assemblies 4 are located at the two ends of the power frame, and are used to connect with two adjacent compartments of the trackless guided tram.

[0031] In this embodiment, an angle sensor is installed on the active steering axle assembly 1 on the bogie to detect the wheel deflection angle.

[0032] In this embodiment, all wheels are equipped with wheel speed sensors to detect the wheel speed.

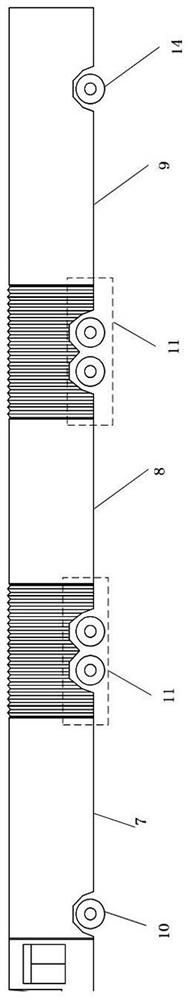

[0033] The present invention further provides a trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com