Device for forming bagged spring strings

A technology of pocket springs and equipment, applied in applications, household appliances, interior decoration, etc., can solve the problems of low gluing rate, increased probability of bag spring breakage, and broken glue, so as to reduce the probability of bag breakage and improve processing Yield, the effect of avoiding glue breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

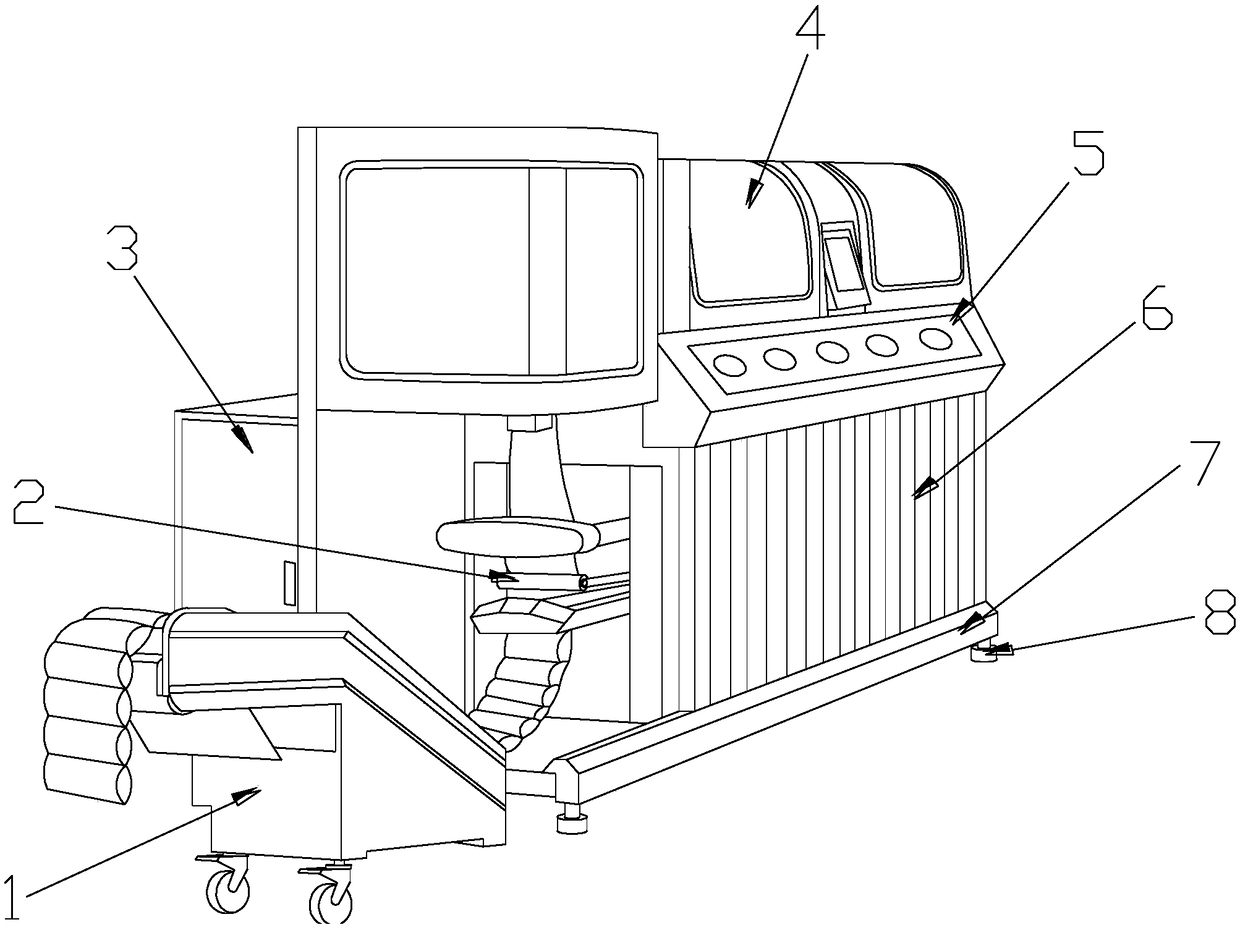

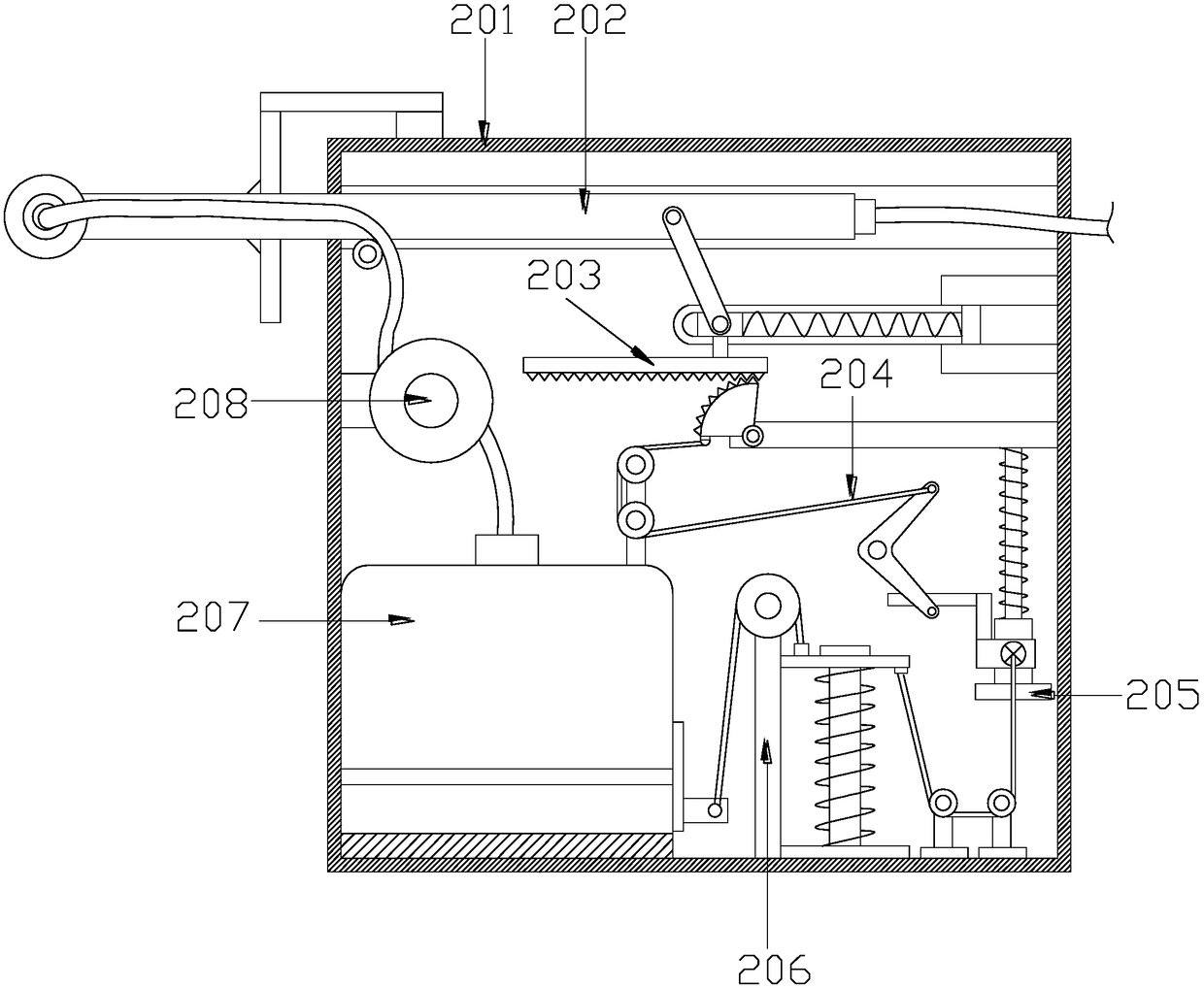

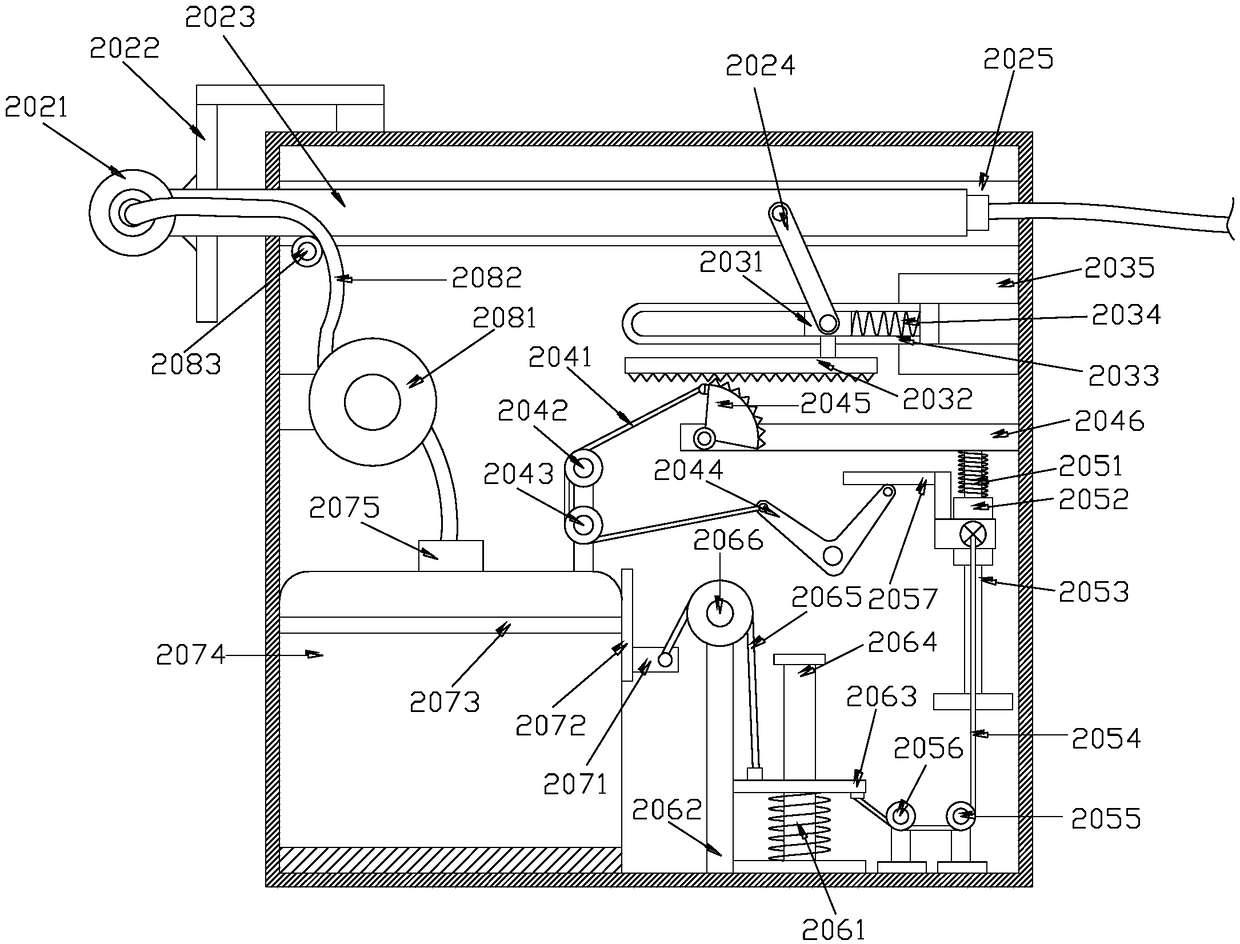

[0021] see Figure 1-Figure 3, the present invention provides equipment for forming pocket spring strings, the structure of which includes a conveyor 1, a gluing device 2, a power host 3, a processing warehouse 4, a control panel 5, a processing host 6, a fixed base 7, and non-slip feet 8 , the anti-skid feet 8 are provided with more than two and are installed on the bottom of the fixed base 7 by buckling, the bottom of the processing host 6 is installed on the upper end of the fixed base 7 by buckling, and the processing chamber 4 is arranged on the processing host 6 upper end, and the right end is provided with control panel 5, and described power host 3 is rectangular structure, and is installed on the left end of processing host 6 by fastening way, and described processing host 6 is provided with gluing device 2 inside, and described conveyor 1 Connected to the front end of the fixed base 7, the gluing device 2 includes a device main body 201, a gluing mechanism 202, a mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com