Anti-puncturing test machine for stab-resistant garment

A technology of anti-puncture and testing machine, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., which can solve the problem of uneven puncture force, inability to prevent puncture-proof testing of protective devices, and human consumption Large and other problems, to achieve a good effect of monitoring the puncture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementations provided according to the present invention will be described in detail below in conjunction with the examples.

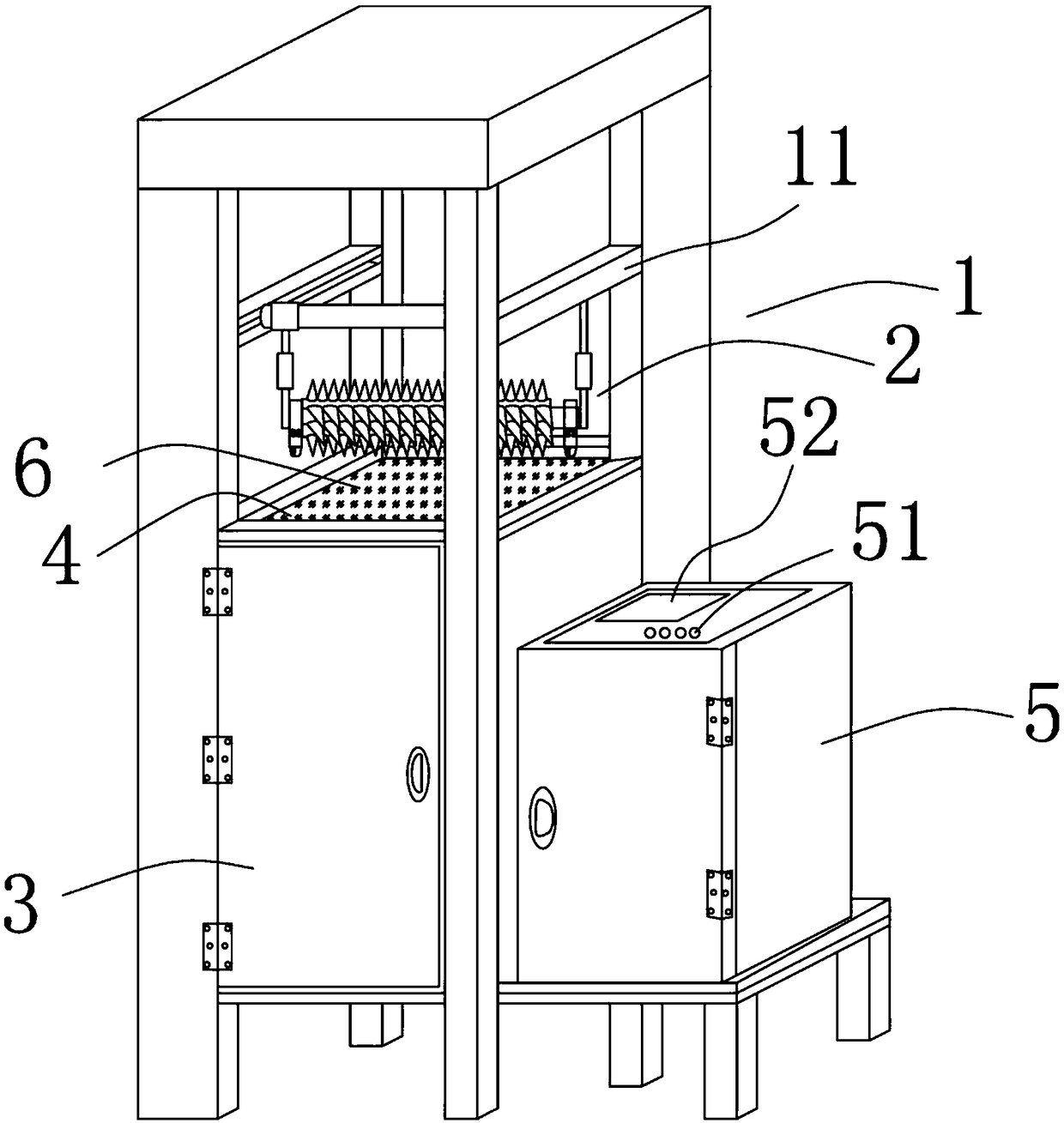

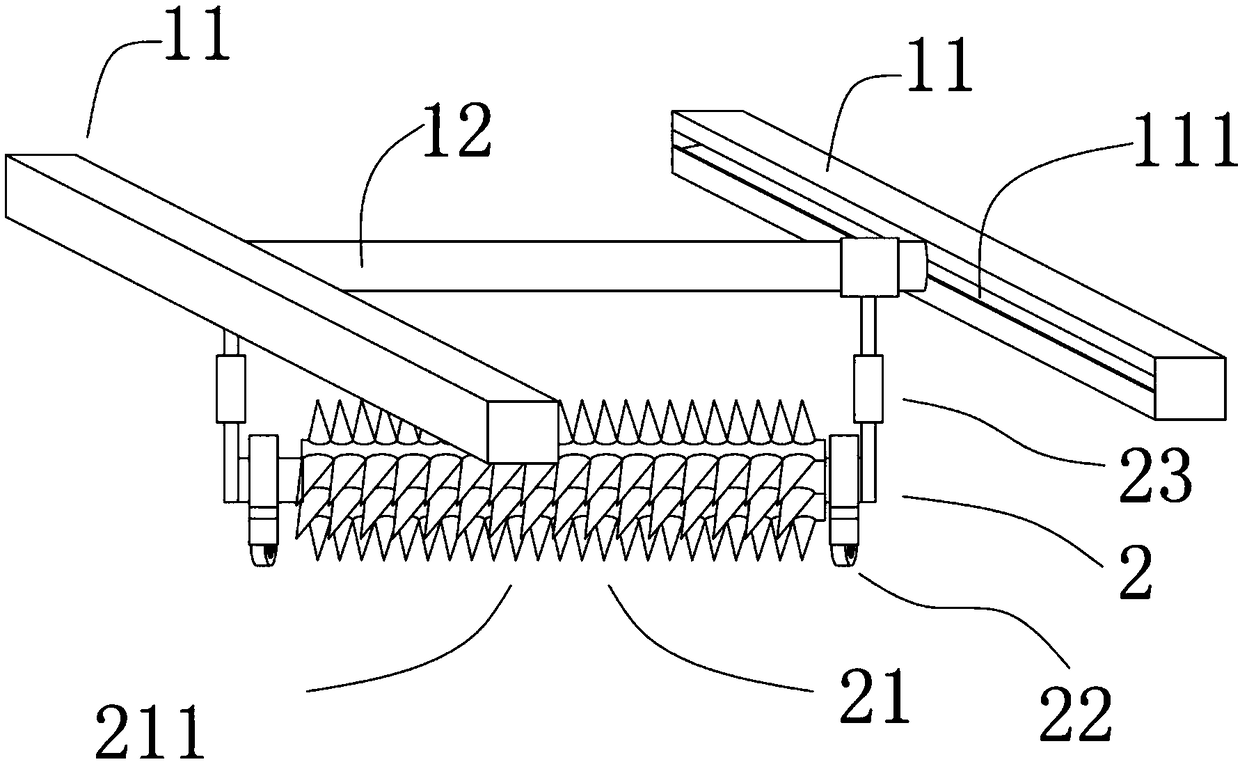

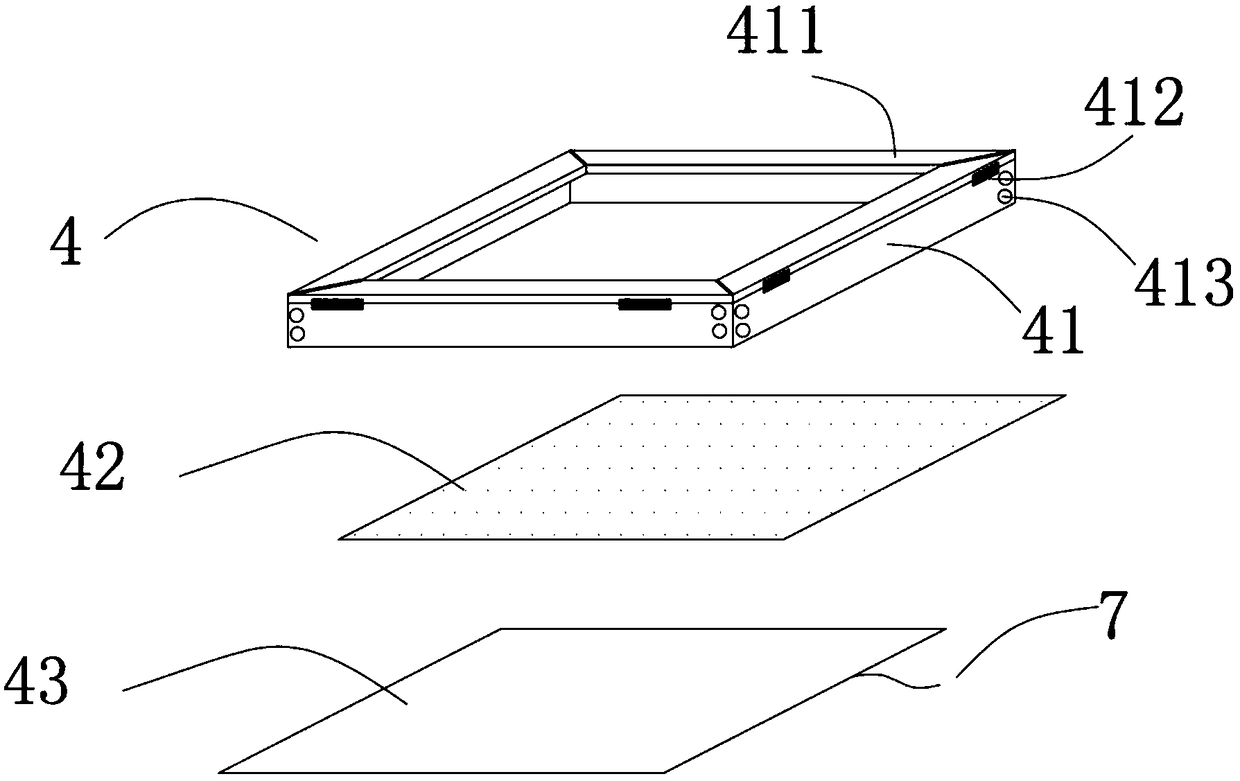

[0023] Such as Figure 1~3 Shown, is a kind of anti-stab clothing anti-piercing testing machine of the present invention, is provided with in the frame 1 and is used for controlling the control box 5 that anti-stab anti-clothing anti-piercing testing machine works, and the side of control box 5 is electrically connected with detection device 3. The detection device 3 is provided with a detection support plate 4 that catches the stab-proof clothing, and a barbed roller 2 is provided directly above the detection support plate 4, and the barbed roller 2 is parallel to the detection support plate 4, and the barbed roller 2 Both ends are provided with a manual telescopic rod 23, the bottom end of the manual telescopic rod 23 is pivotally connected with the barbed roller 2, the top end of the manual telescopic rod 23 is socketed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com