Fluorescent display screen containing up-conversion luminescent material and its preparation method and application

A technology of luminescent materials and display screens, applied in optics, optical components, instruments, etc., can solve the problems of OLED technology threshold and investment quota, high price, and challenges of micro-display, and achieve long service life and low cost. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a fluorescent display screen containing an up-conversion luminescent material and a preparation method thereof.

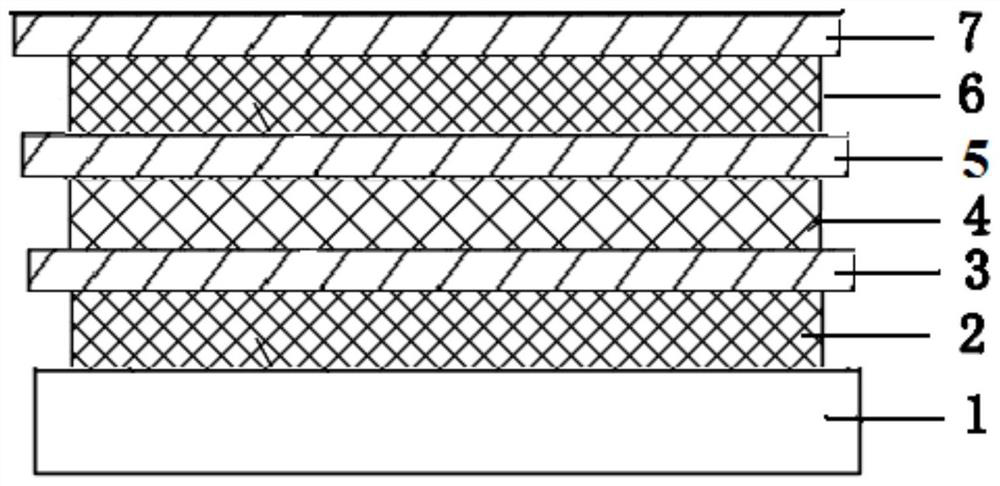

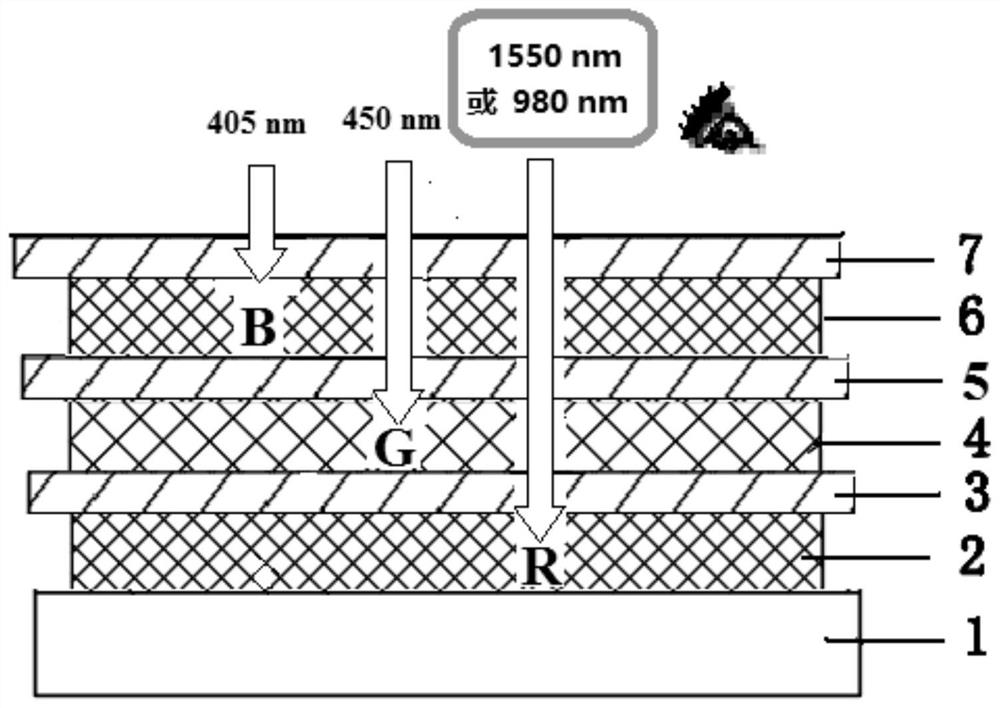

[0061] A fluorescent display containing up-converting luminescent materials, such as figure 1 As shown, it consists of a substrate (1), a red fluorescent material layer (2), a second isolation layer (3), a green fluorescent material layer (4), a first isolation layer (5), a blue fluorescent material layer (6) and The protective layer (7) is stacked sequentially.

[0062] The substrate 1 is made of glass.

[0063] The material of the red fluorescent material layer is NaYF doped with ytterbium and erbium 4 ultrafine nanocrystals. Its preparation method is, Y 2 o 3 , Yb 2 o 3 and Er 2 o 3 According to the molar ratio m(Y 3+ ):m(Yb 3+ ):m(Er 3+ )=70:28:2 was dissolved in dilute hydrochloric acid to obtain a rare earth chloride precursor. Add 1 mmol of the above-mentioned rare earth chloride precursor dropwise into a mixed so...

Embodiment 2

[0080] This embodiment provides a fluorescent display screen containing an up-conversion luminescent material and a preparation method thereof.

[0081] The structure and preparation method of the fluorescent display screen containing the up-conversion luminescent material in this embodiment are the same as those in Embodiment 1, except that the red fluorescent material layer is different.

[0082] Wherein, the material of the red fluorescent material layer is KMnF doped with ytterbium, erbium and thulium 3 . The preparation method is as follows: 1.5g of KOH, 2mL of water, 4mL of ethanol and 9mL of OA (90wt%) were mixed at room temperature for ten minutes to obtain a white viscous solution. Then sequentially add 10mL of MnCl 2 solution (0.2mol / L), 15.5mg of YbCl 3 ·6H 2 O (0.4mmol), 1.5mg of ErCl 3 ·6H 2 O (0.04mmol) and 1.5mg of TmCl 3 ·6H 2 O (0.04mmol), stirred vigorously for 20min. Add 8 mL of KF solution (1.25 mol / L) and age for 1 hour to obtain a mixture. The m...

Embodiment 3

[0087] This embodiment provides a fluorescent display screen containing an up-conversion luminescent material and a preparation method thereof.

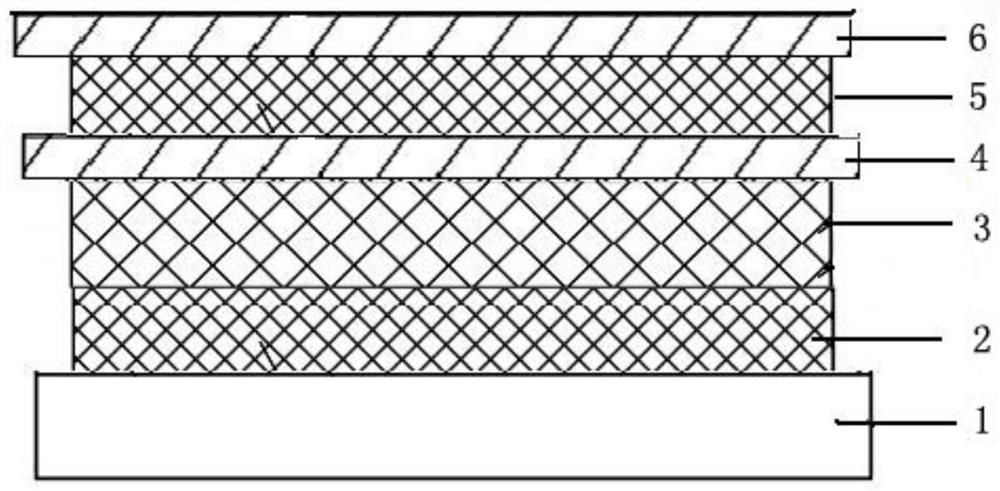

[0088] The raw materials and preparation method of the fluorescent display screen containing up-conversion luminescent material in this embodiment are the same as those in Example 2, except that there is no second isolation layer between the green fluorescent material layer and the red fluorescent material layer in the fluorescent display screen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com