Retro-reflective structure body and preparation method thereof

A manufacturing method and structure technology, applied in the direction of optics, instruments, optical components, etc., can solve the problems of poor bonding of adhesives, poor reflective ability, and low anti-slip value, and achieve increased bonding force, increased anti-slip value, Not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

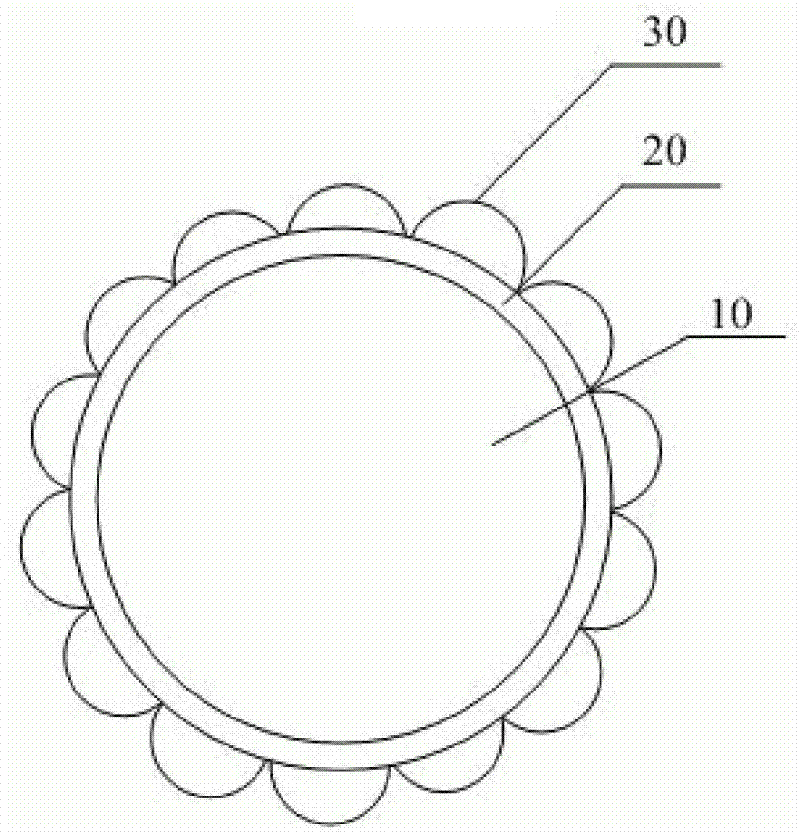

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

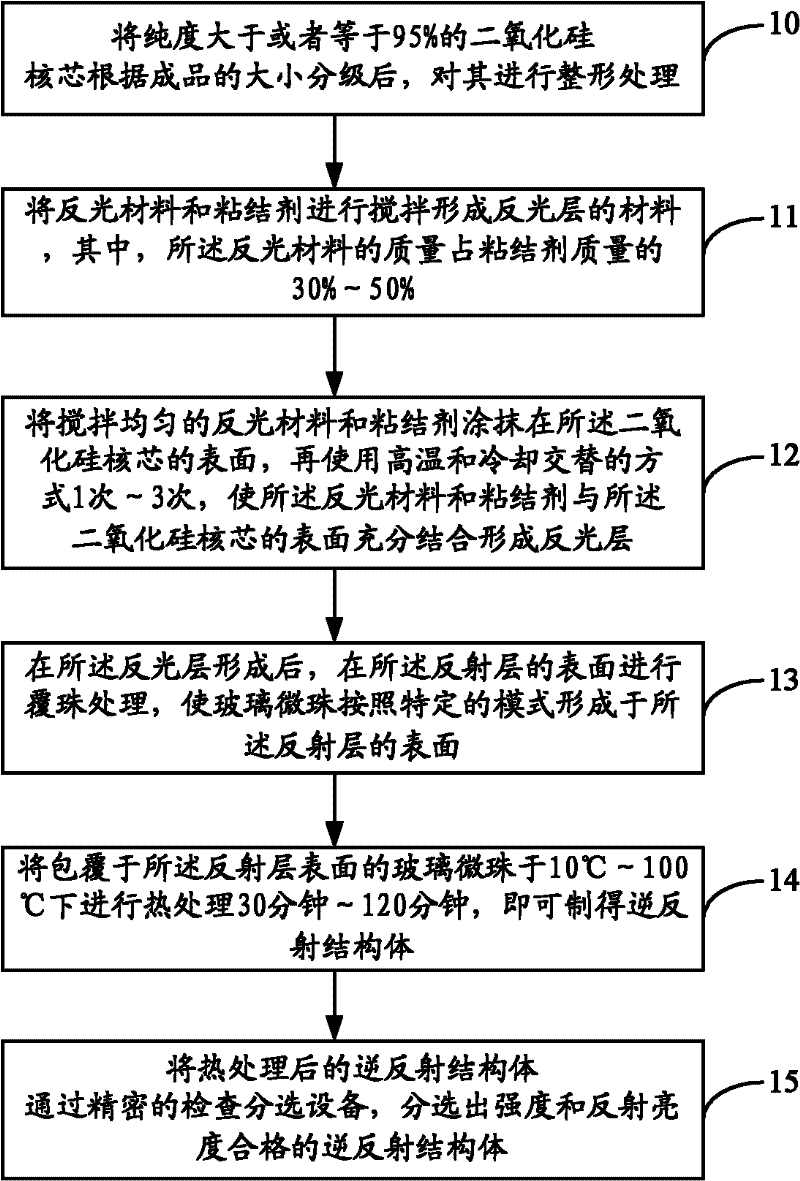

[0033] figure 1 It is a schematic flow chart of the manufacturing method of the retroreflective structure of the present invention. Such as figure 1 As shown, the manufacturing method of the retroreflective structure includes the following steps:

[0034] Step 10, after grading the silica cores with a purity greater than or equal to 95% according to the size of the finished product, they are subjected to shaping treatment.

[0035] The silicon dioxide core is a spherical body with a diameter of 0.1 mm to 2 mm. The silica core is made of natural high-purity river sand or high-purity silica ore, wherein the silica content is greater than or equal to 95%. The grading of the core is mainly based on the size of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com