A New Composite Tracking Control Method for Chemical Batch Process

A technology of composite tracking and control methods, applied in the field of automation, can solve the problems of chemical intermittent process lag, system stability and control performance decline, etc., and achieve the effect of good control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Take the water injection process control of a three-capacity water tank as an example:

[0057] Each water injection process in the process can be regarded as an intermittent process, and the adjustment method is to control the height of the liquid level by adjusting the flow rate of the pump.

[0058] Step 1. Establish a model of a chemical batch process, specifically:

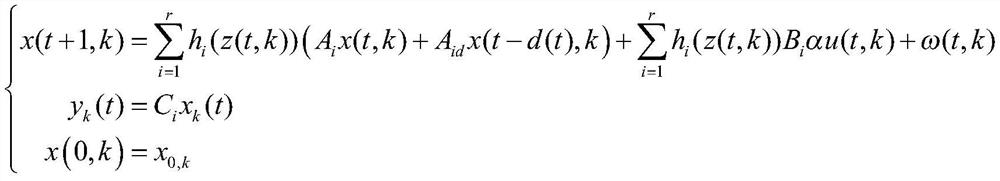

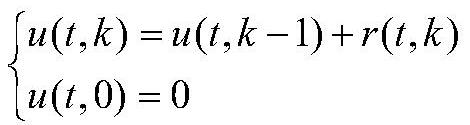

[0059] In the chemical batch process, the discrete state space model is established for the system with partial actuator failure as follows:

[0060]

[0061] Among them, t represents a finite discrete time, k is a periodic index, and k takes any natural number; i=1,2,...r; r is any non-zero natural number; z(t,k) represents the state of the liquid level in the water tank;

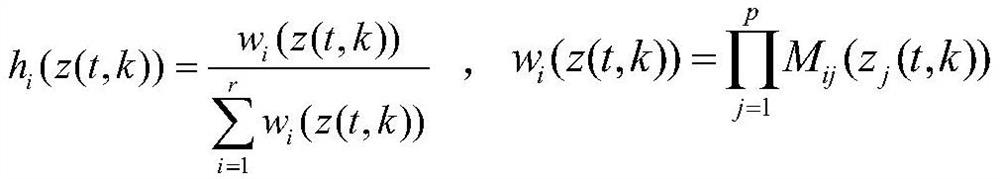

[0062]

[0063] z j (t, k) is the jth elastic language variable, j=1,2,...,p, p represents the number of conditional language variables; M ij (z j (t,k)) is z j (t,k) in an elastic language set M ij The membership funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com