Backstepping finite-time sliding mode control method for multi-joint industrial manipulator

An industrial machinery, limited time technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., to achieve the effect of strong robust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

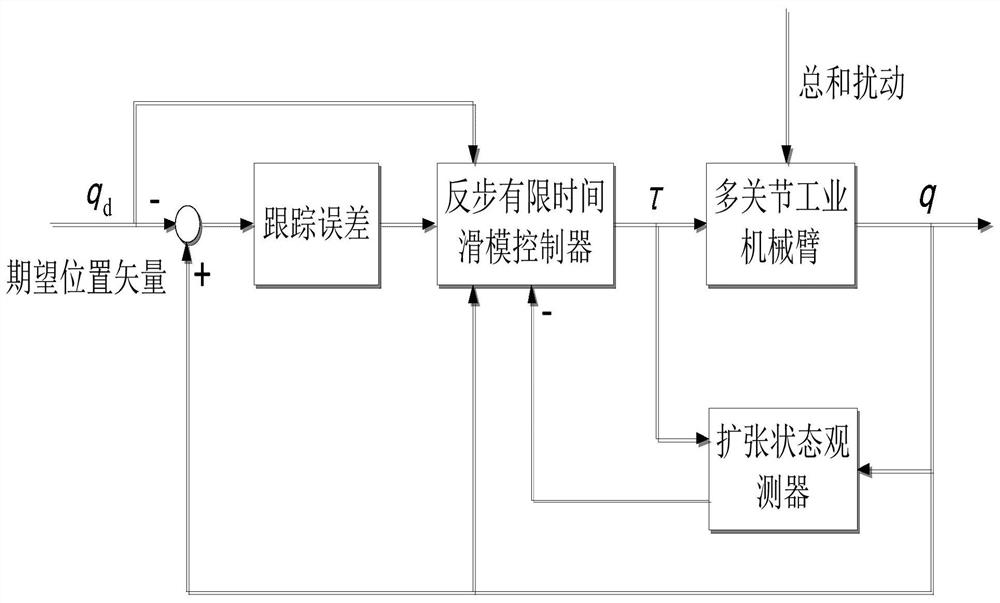

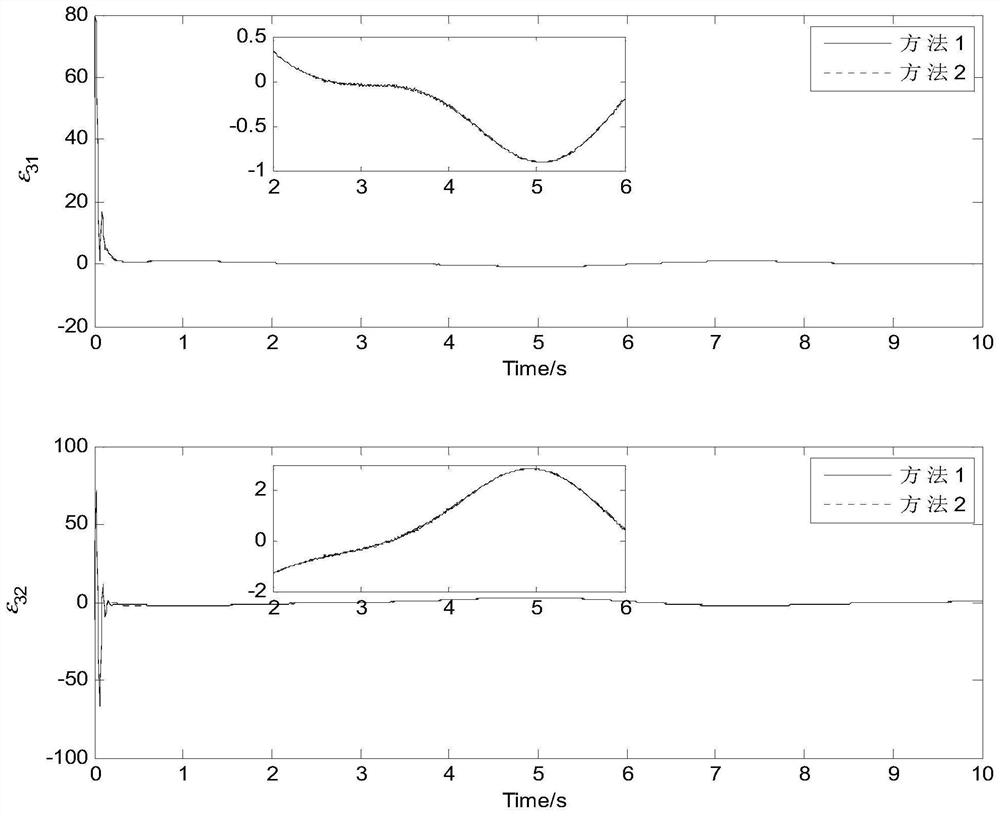

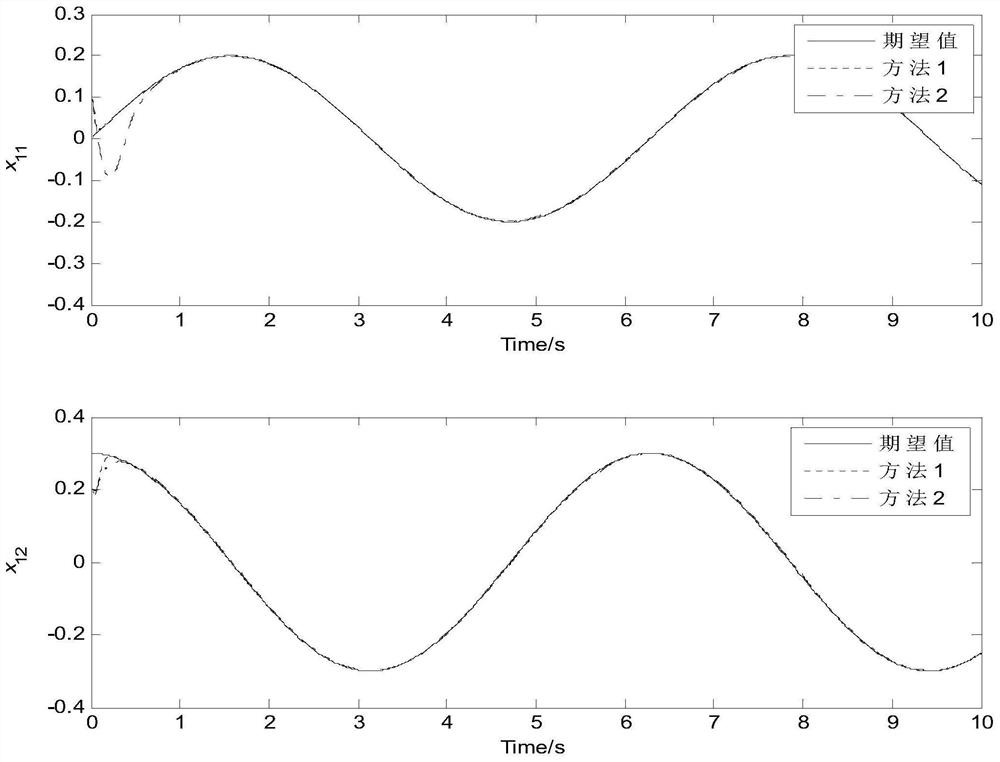

[0066] Such as figure 1 — Figure 5 As shown, the multi-joint industrial manipulator backstepping finite-time sliding mode control method is characterized in that it includes the following steps:

[0067] (1) Establish a multi-joint industrial manipulator system model, the specific process is as follows:

[0068] For the n-joint industrial manipulator system, if the influence of dynamics, friction and disturbance is considered, the dynamic model can be expressed as:

[0069]

[0070] In formula (1), represent the position, velocity and acceleration vector of the joint respectively; M(q)∈R n×n is the positive definite inertia matrix of the system; is the centrifugal force and Coriolis force matrix; G(q)∈R n is the gravity term vector acting on the joint; τ∈R n is the control torque vector, which represents the driving torque acting on each jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com