Electric connector assembly

A technology of electrical connectors and docking connectors, which is applied in the direction of vehicle connectors, connections, parts of connection devices, etc., to achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

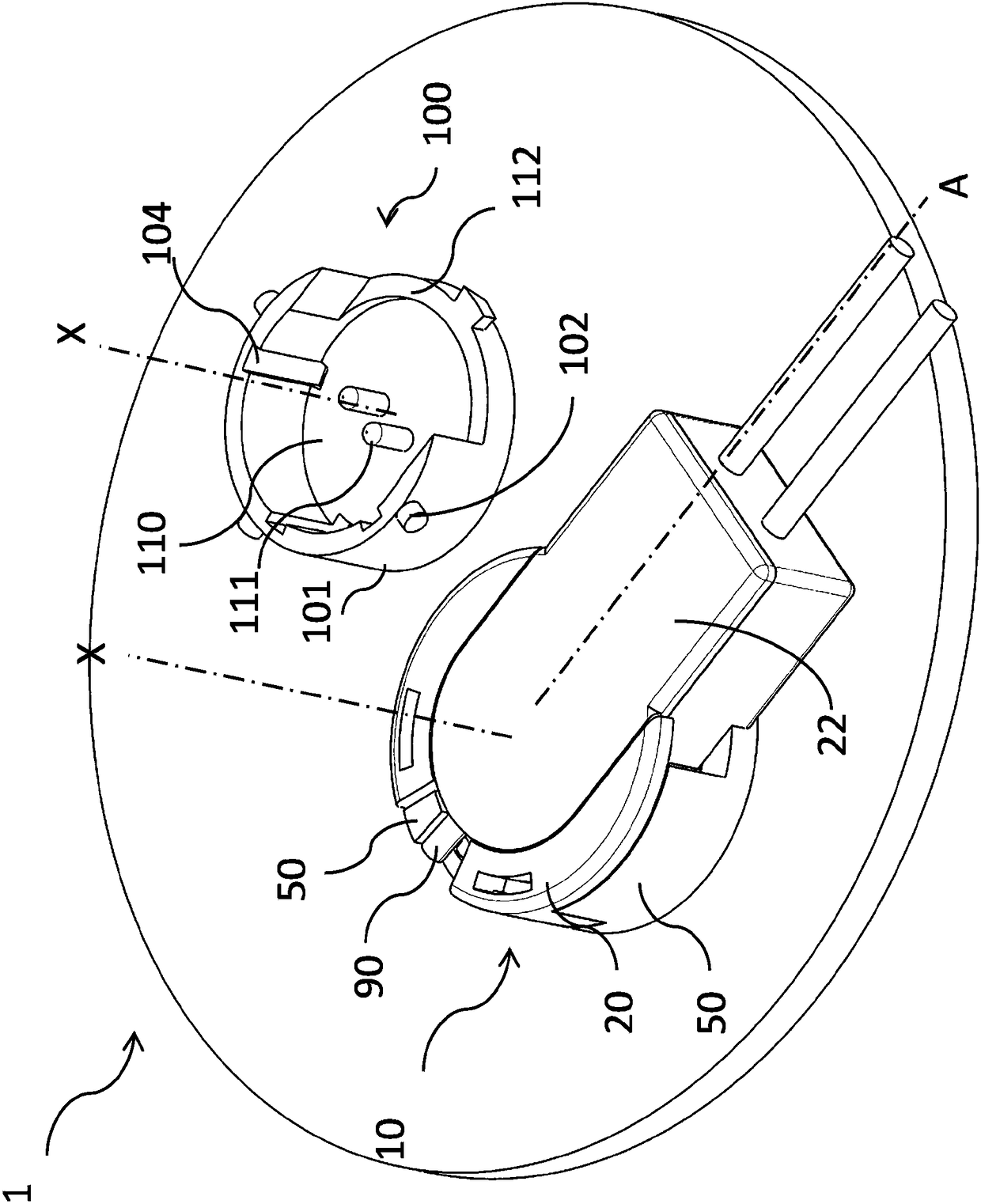

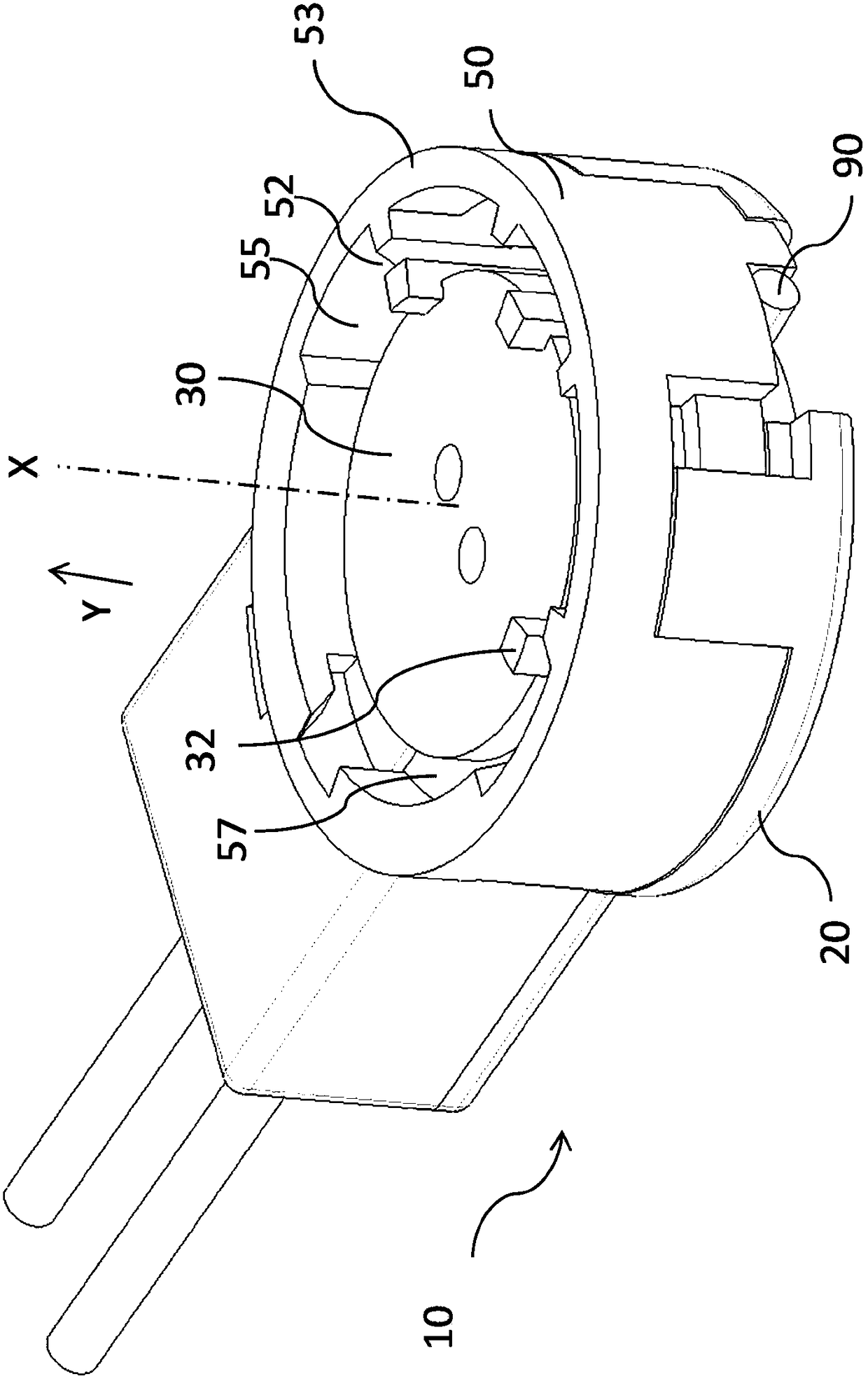

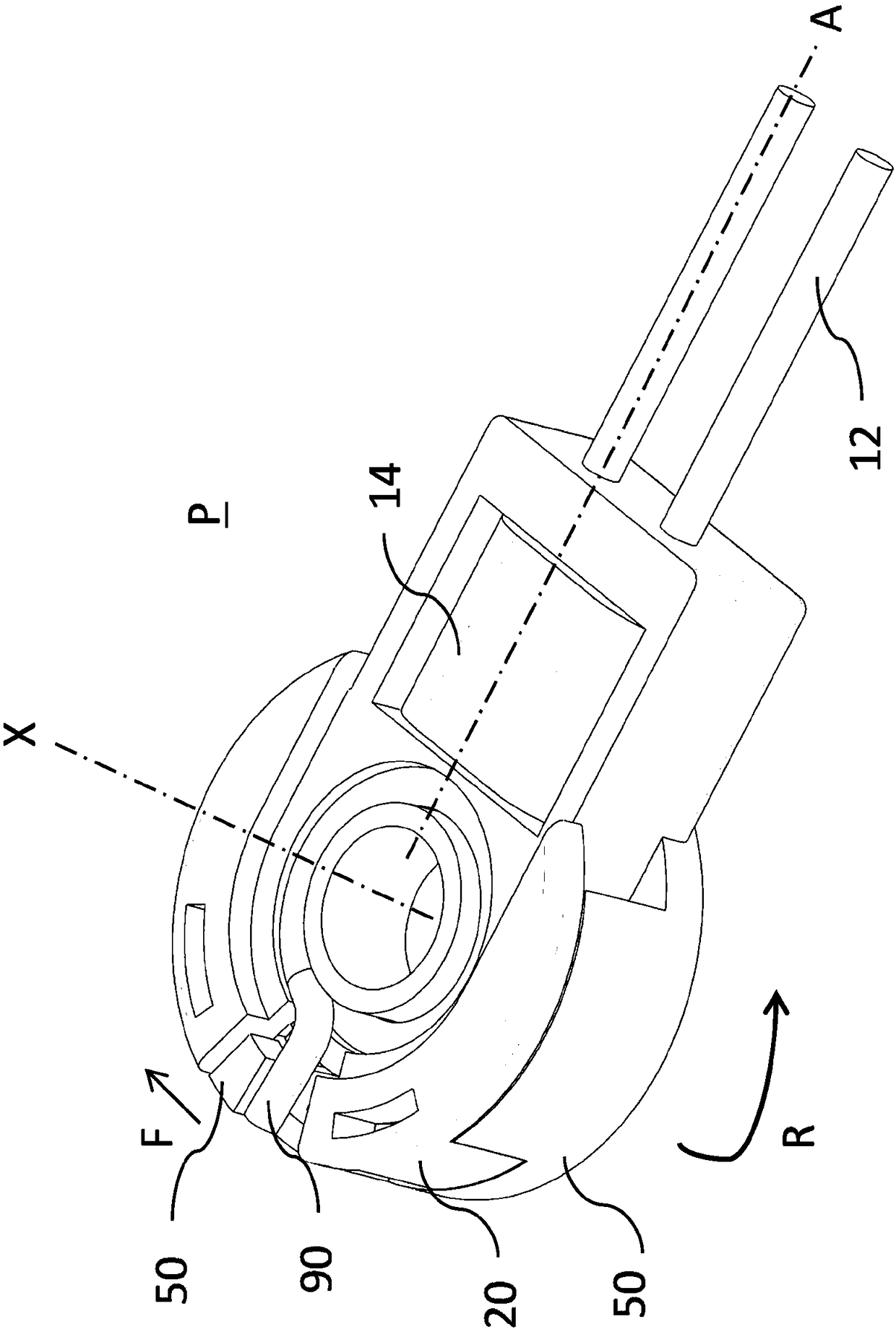

[0027] figure 1 An electrical connector assembly is shown with two butt connectors 100 mounted side by side on the housing wall 1 of the airbag ignition mechanism. The plug 10 is connected to one of the mating connectors 100 . The plug 10 has an annular locking ring 50 , movable about an insertion axis X, attached to the plug body 20 and surrounding the contact holder portion 30 concentrically, and a plug body 20 comprising a contact holder portion 30 . Elastic element 90 ( image 3 ) keeps the locking ring 50 in the rest position P. The plug body 20 has a flat elongated shape whose dimension along the housing axis A at right angles to the insertion axis X is larger than the dimension along the direction of the insertion axis. The docking connector 100 includes a plug receiving portion 110 adapted to receive and electrically and mechanically connect the male portion 30 of the plug 10 . The docking connector 100 includes a collar 101 surrounding a plug receiving portion 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com