Hexagonal irregularly-shaped hole screw

A technology for special-shaped holes and screws, which is applied in the direction of screws, bolts, threaded fasteners, etc., and can solve problems such as incomplete forming, pressure loss, and insufficient contact area of screwdrivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

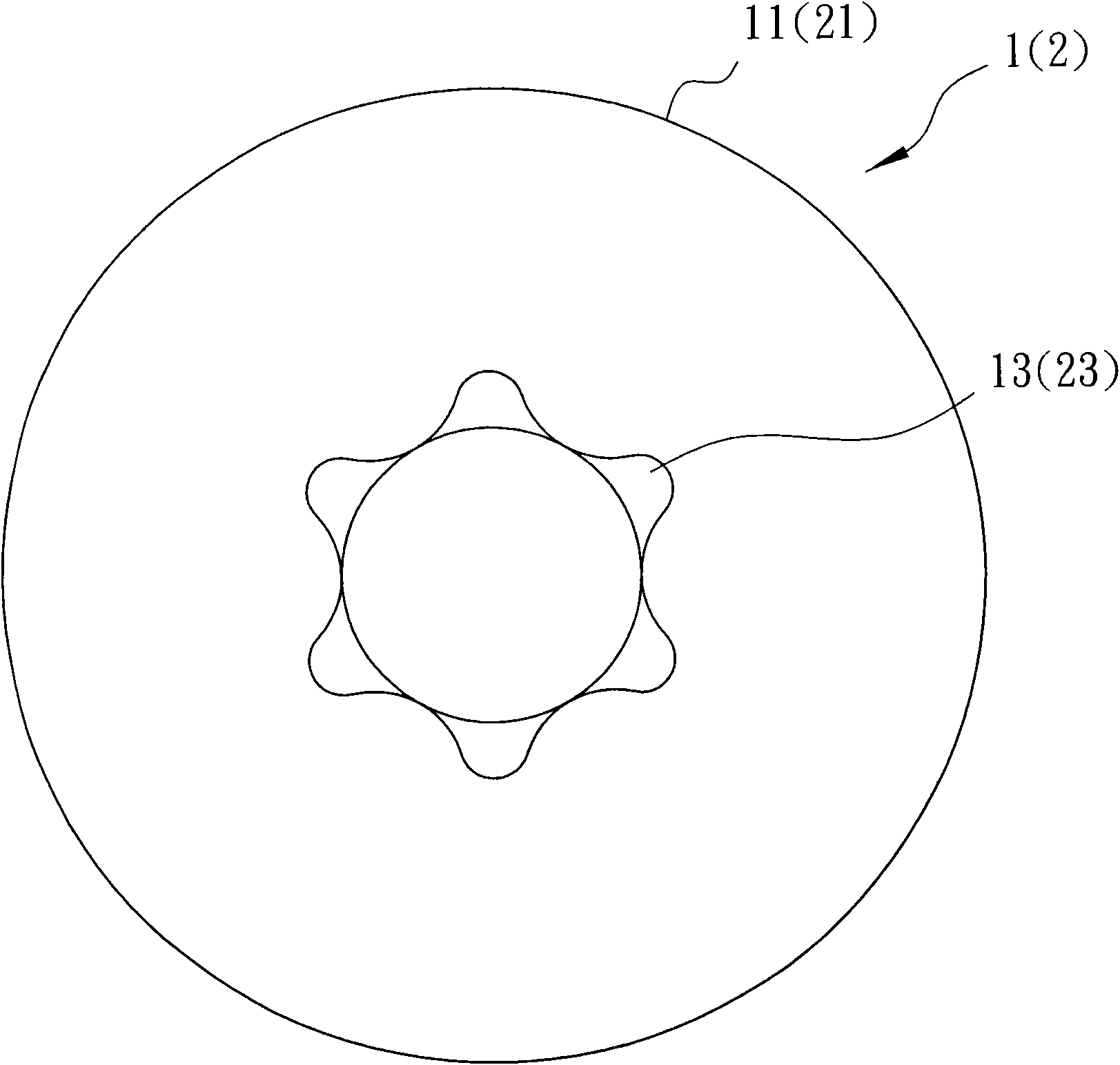

[0016] The hexagonal special-shaped hole screw of the present invention will be described in detail below through preferred embodiments and accompanying drawings. Before the present invention is described in detail, it is noted that in the following description, similar elements are denoted by the same numerals.

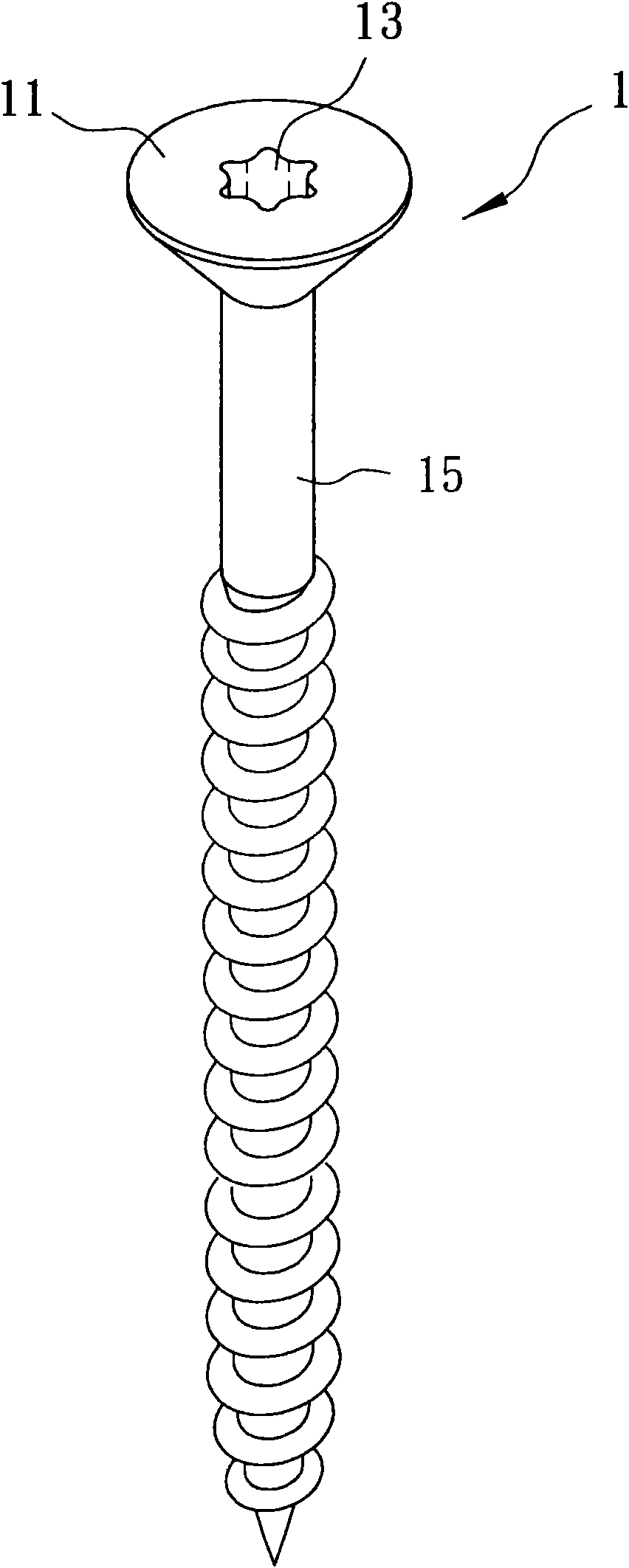

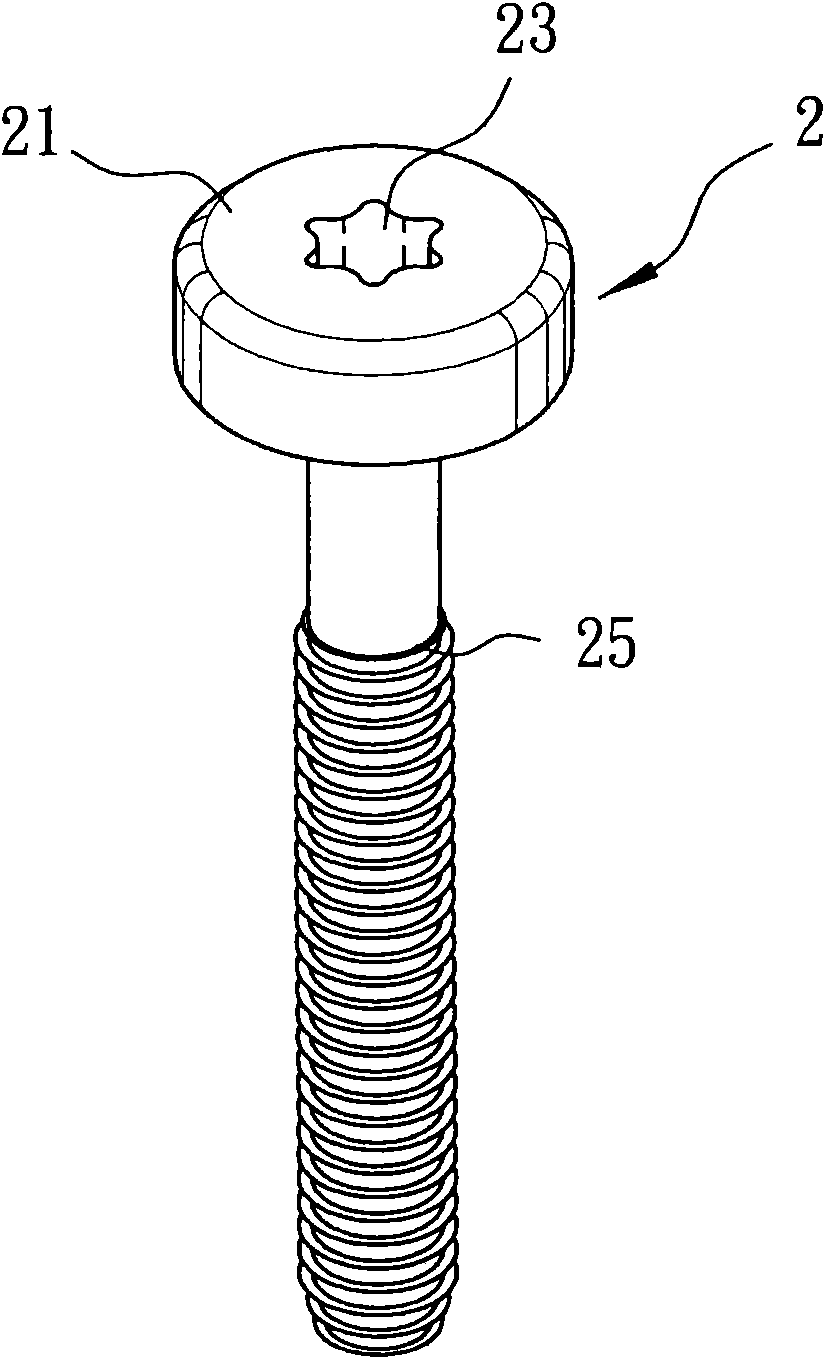

[0017] refer to Figure 4 , the first preferred embodiment of the hexagonal special-shaped hole screw 3 of the present invention is a wood screw used for locking connection between wood workpieces, and the applicator utilizes a screwdriver of a corresponding shape to screw it into the workpiece. Of course, The hexagonal special-shaped hole screw 3 can also be used for temporary insertion of the existing standard hexagonal torx screwdriver.

[0018] The hexagonal special-shaped hole screw 3 includes a screw head 30 for inserting and driving a screwdriver (not shown in the figure), and a screw rod 32 connected with the screw head 30 and forming a thread 320 on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com