Pressure relief device of switch cabinet and switch cabinet

A technology of pressure relief device and switchgear, which is applied in the direction of switchgear, switchgear setting, substation/switch layout details, etc., and can solve problems such as potential safety hazards outside the cabinet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

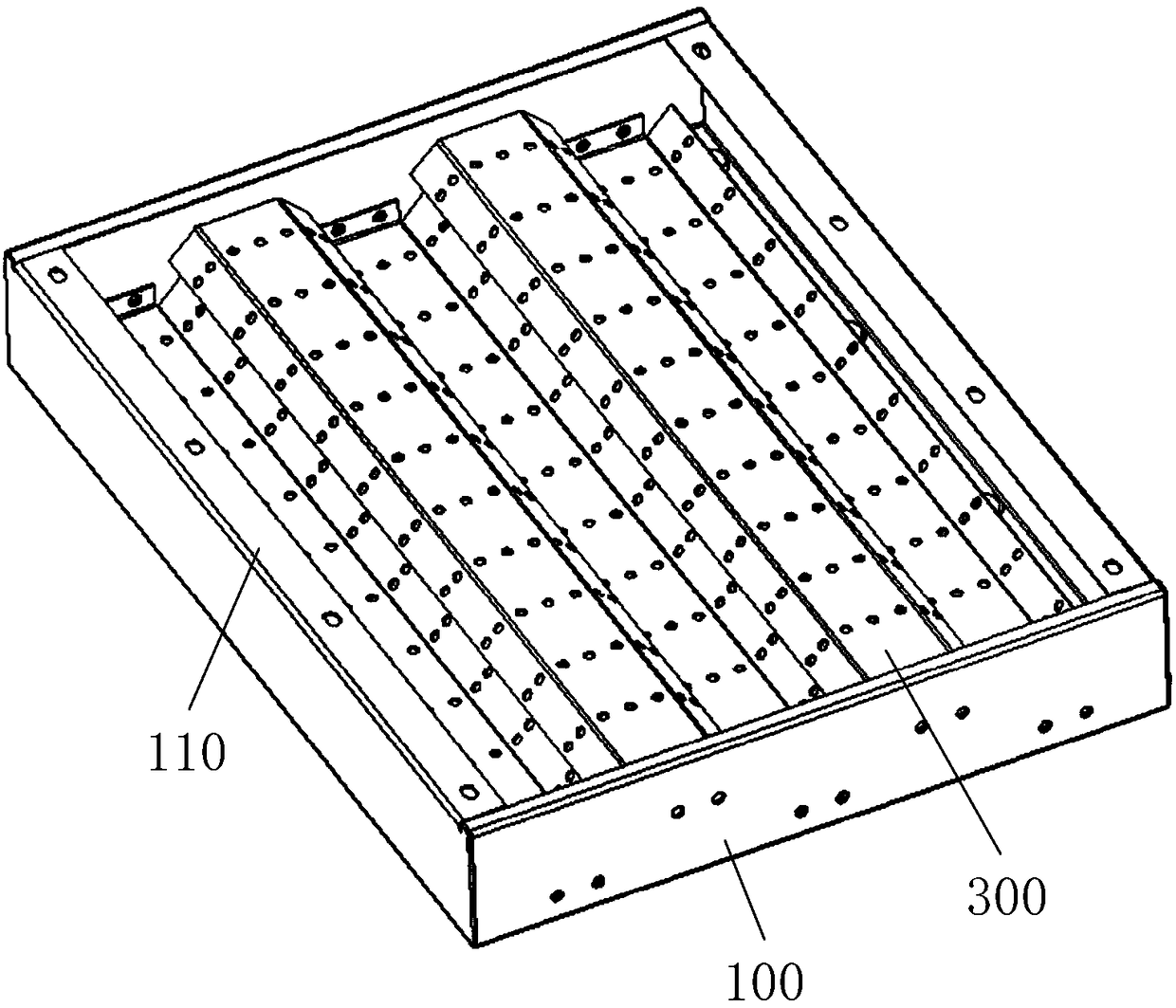

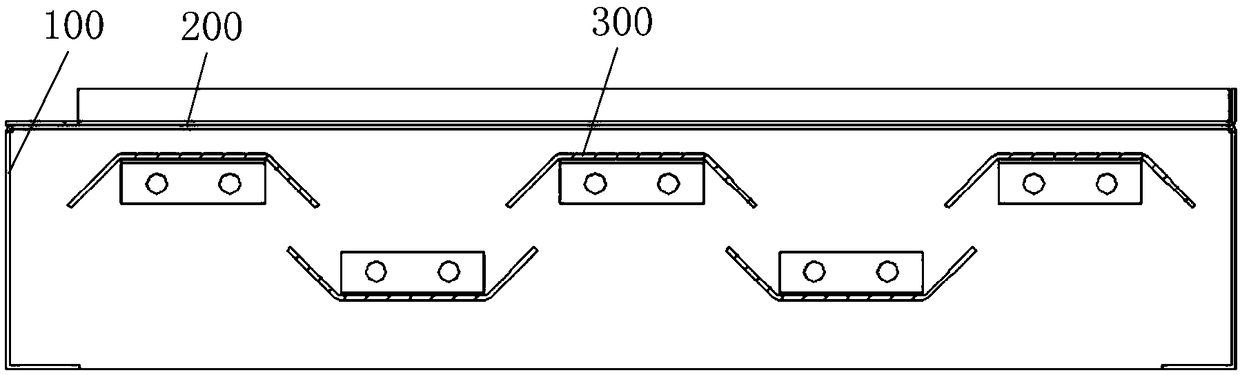

[0033] The switch cabinet pressure relief device provided by the embodiment of the present invention includes: a cabinet top plate 100, a pressure relief plate 200 and a plurality of arc baffles 300, and the opposite sides of the arc baffles 300 have bent edges to form a buffer cavity ;

[0034] The top plate 100 of the cabinet has a pressure relief chamber, the pressure relief chamber runs through the top plate 100 of the cabinet, and a plurality of arc baffles 300 are all arranged in the pressure relief chamber, and arc discharge gaps are left between adjacent arc baffles 300, each The bent edge of the arc baffle 300 is opposite to the buffer cavity of the adjacent arc baffle 300;

[0035] The pressure relief plate 200 covers the pressure relief chamber, the first side of the pressure relief plate 200 is fixedly connected with the top panel 100 of the cabinet, the second side of the pressure relief plate 200 is detachably connected with the top panel 100 of the cabinet, and ...

Embodiment 2

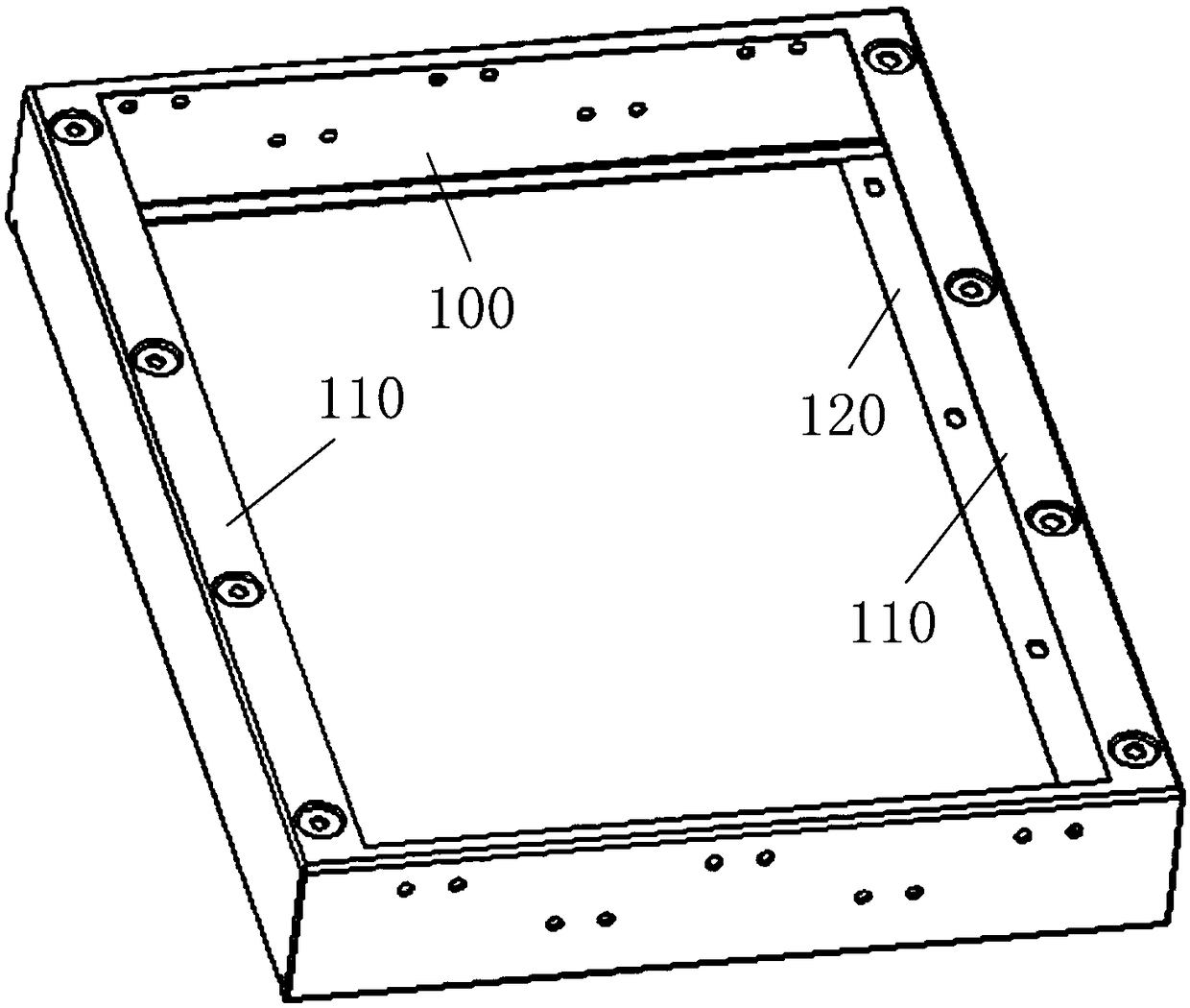

[0056] The second embodiment provides a switchgear to alleviate the technical problem of potential safety hazards in the pressure relief of the switchgear in the related art.

[0057] like Image 6 As shown, the switch cabinet provided by the embodiment of the present invention includes a cabinet body and the above-mentioned switch cabinet pressure relief device. The top of the 430 is equipped with a switch cabinet pressure relief device.

[0058] Further, the pressure relief device of the switch cabinet is connected with the cabinet by bolts.

[0059] The second connection plate 120 of the cabinet top plate 100 is provided with a plurality of through holes, and the plurality of through holes are distributed at intervals along the length direction of the second connection plate 120, and the bolts pass through the through holes on the second connection plate 120 and the cabinet. The body thread fits, so that the switchgear pressure relief device is installed on the cabinet bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com