Milk warmer capable of achieving water level variation and constant-temperature control

A technology of constant temperature control and milk warmer, which is applied in heating devices, cooking utensils, household appliances, etc. It can solve the problems that are not conducive to the health of children or the elderly, easily destroy the nutrition of milk or juice, and cannot keep milk or juice warm. , to ensure the effect of heat preservation, improve the effect of heating and heat preservation, and ensure the effect of human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

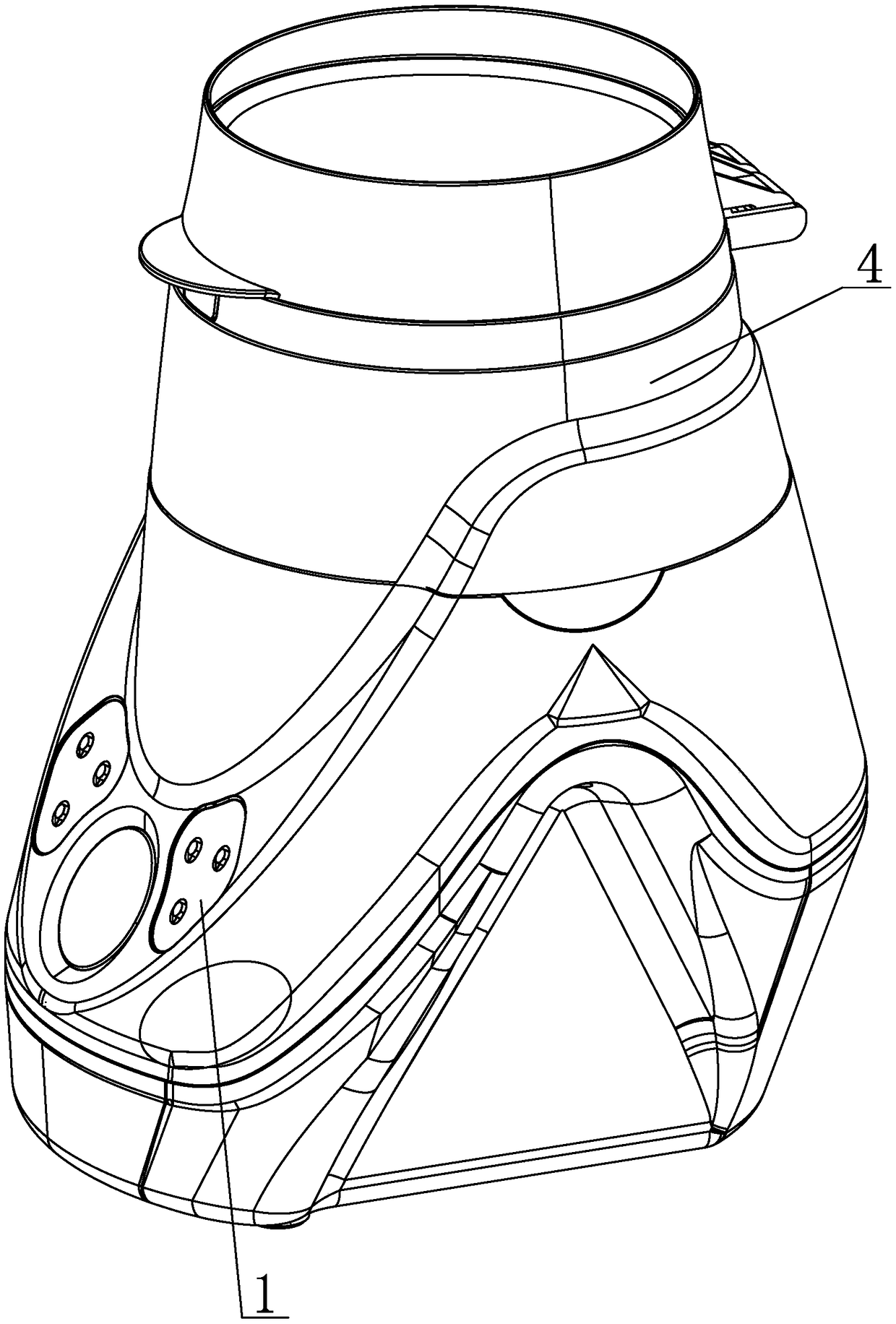

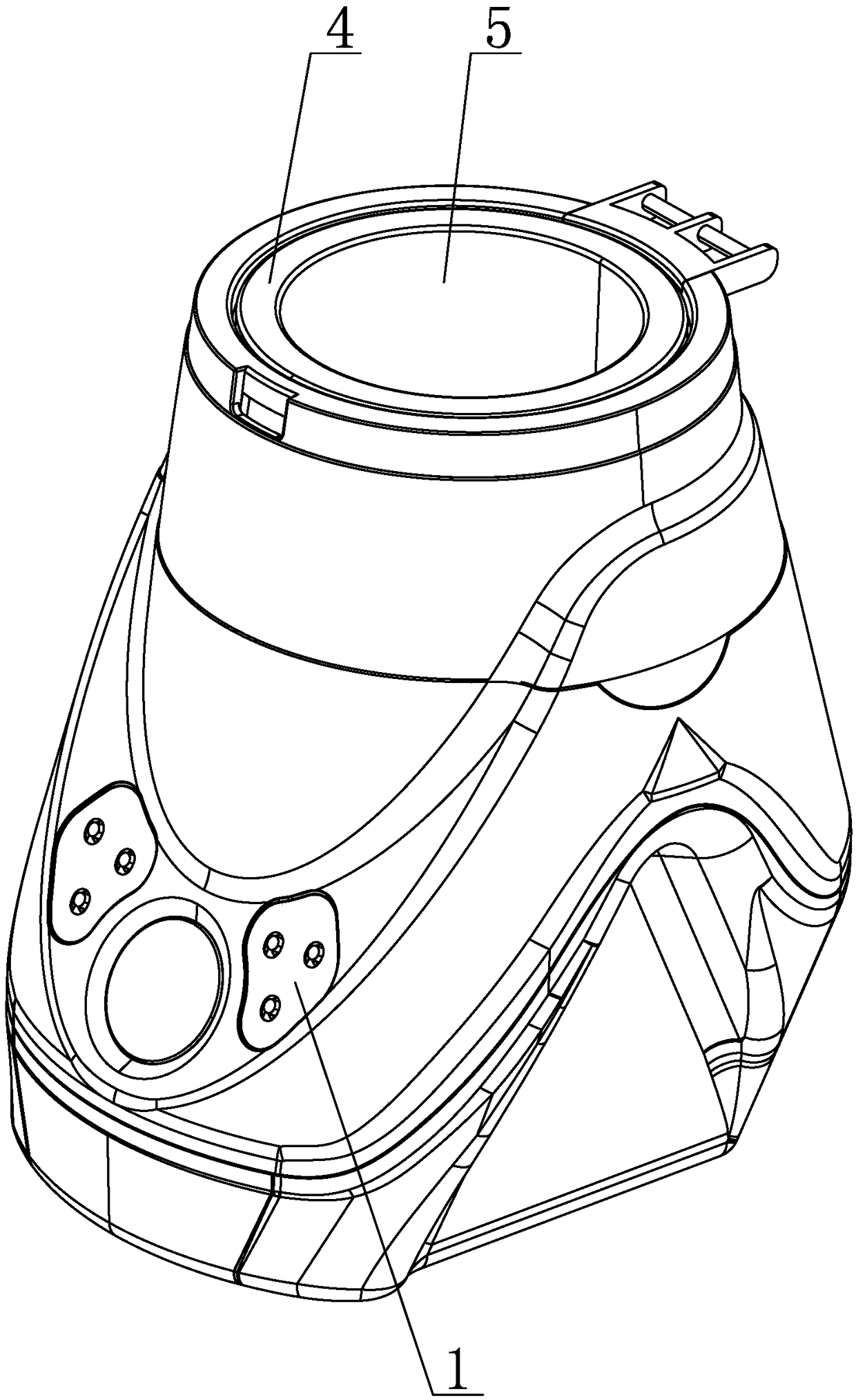

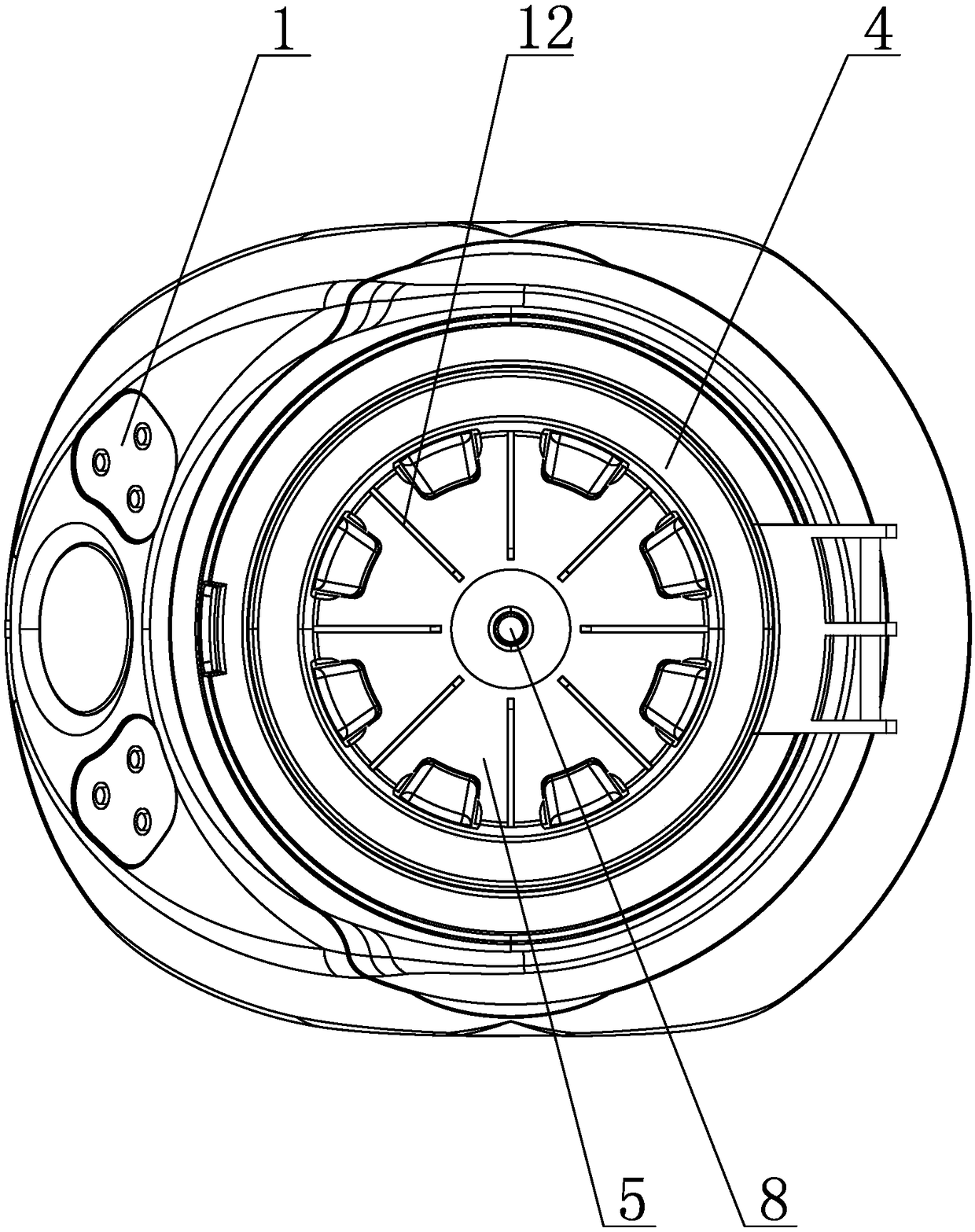

[0032] According to attached Figure 1 to Figure 7 As shown, the milk warmer with adjustable water level and constant temperature control of the present invention includes a heating base 1 with a heating element 2 and a shell assembly installed on the heating base 1 . Wherein, the heating seat 1 is provided with a heating chamber 1 for storing and heating water. The housing assembly includes a milk warming shell 4 with a milk warming chamber 5 and a sealing block 7 that makes the milk warming shell 4 hermetically assembled on the heating chamber 3. When the shell assembly is assembled on the heating seat 1, the milk warming shell 4 is located Above the heating chamber 3, the sealing block 7 is located between the warm milk shell 4 and the heating chamber 3, and the bottom of the warm milk shell 4 is provided with a guide pipe 8 which communicates with the warm milk ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com