A control method of a water softener of a dishwasher and the dishwasher

A technology of water softener and control method, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, washing control program, etc., which can solve the problems of insufficient water volume, artificial water addition, incomplete drainage of salt water, etc. problems, to achieve the effect of improving the practical experience and reducing the amount of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

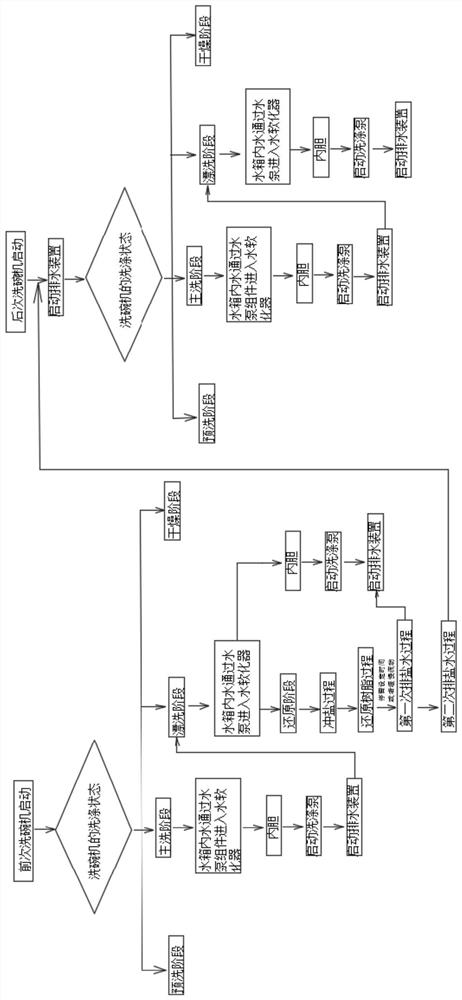

[0020] See attached figure 1 , this embodiment provides a control method for a water softener of a dishwasher. The operation phase of the dishwasher includes a reduction phase of the water softener, and the reduction phase includes a salt flushing process, a resin reduction process, and the first draining of salt water. process and the second brine discharge process, the first brine discharge process and the second brine discharge process are after the salt flushing process and the reduction process, and the first brine discharge process and the second brine discharge process are respectively done after the previous wash and before the next wash;

[0021] When the dishwasher enters the process of draining salt water for the first time, the water pump of the dishwasher transfers the remaining water in the water tank of the dishwasher into the resin cavity of the water softener and discharges the high-concentration brine in the resin cavity out of the dishwasher, and then stops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com