Apparatus used for sorting fine grained metal ore

A technology for fine particles and metals, which is applied in the field of fine-grained metal sorting devices, can solve the problems of inability to obtain filtration separation and low separation efficiency, and achieve the effects of advanced methods, small particles and sufficient crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

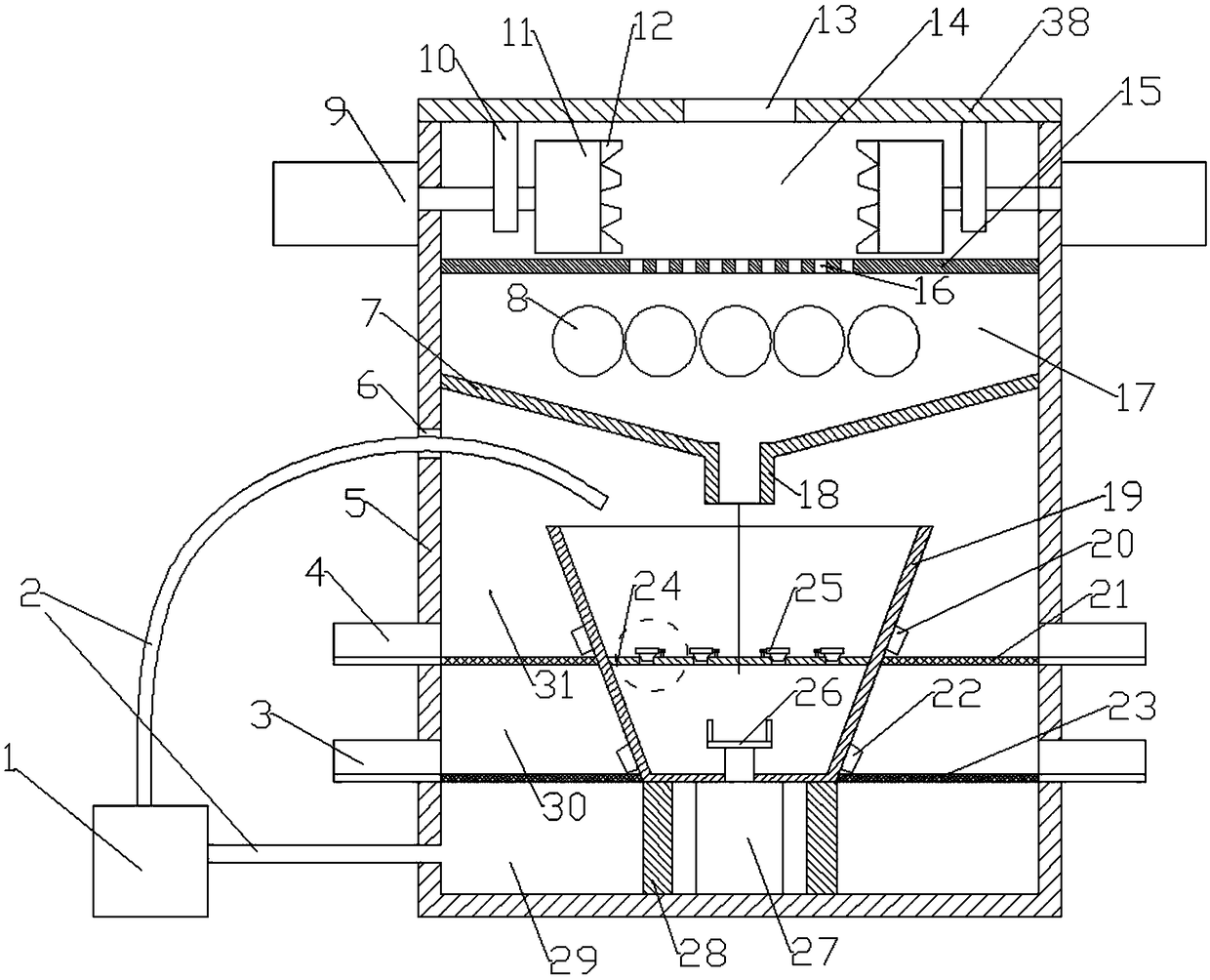

[0014] The present invention will be further described below in conjunction with accompanying drawing:

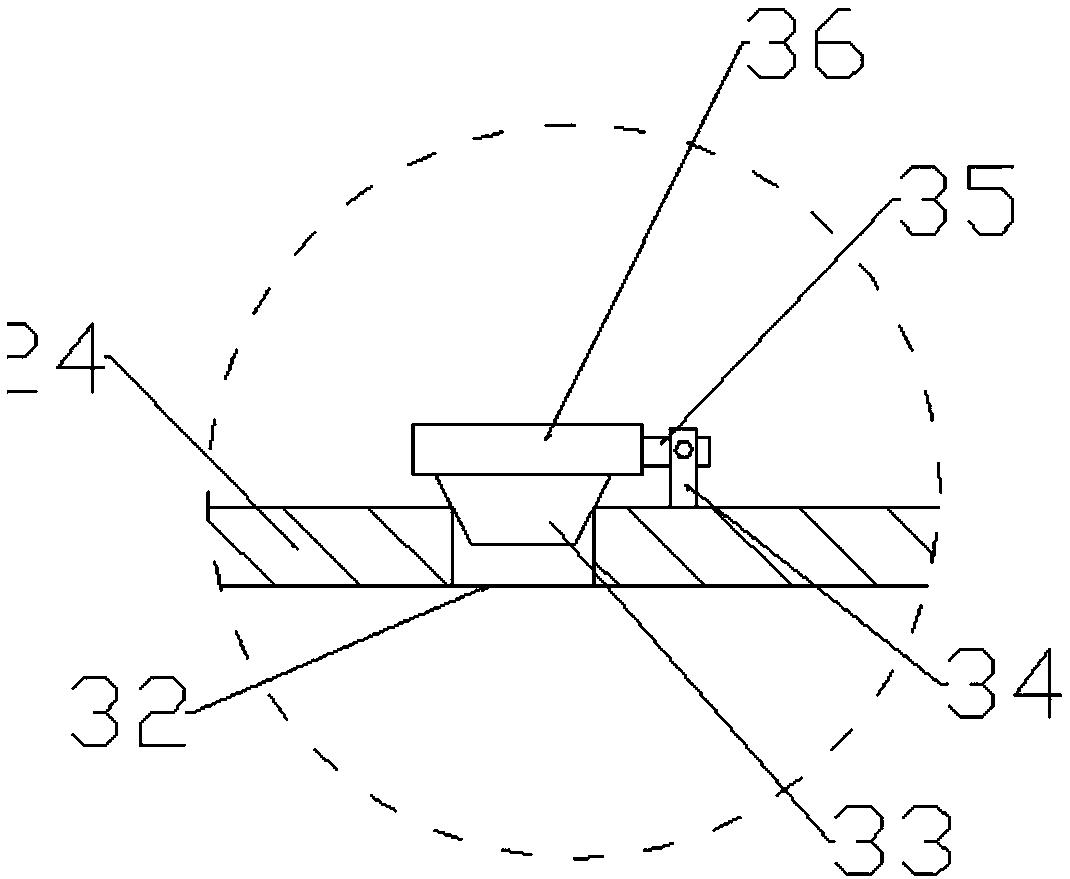

[0015] With reference to accompanying drawing: in the present embodiment, this kind of fine-grained metal sorting mining device comprises a cuboid housing 5 and an upper cover 38 at the top of the housing 5, and the middle of the upper cover 38 is provided with a feeding port 13, and the The interior of the housing 5 is sequentially provided with a blanking plate 15, a funnel plate 7, a second filter screen 21 and a first filter screen 23 from top to bottom, and the crushing chamber 14 is between the upper cover 38 and the blanking plate 15; Between the blanking plate 15 and the funnel plate 7 is a grinding cavity 17, between the funnel plate 7 and the second filter screen 21 is a second material cavity 31, between the second filter screen 21 and the first filter screen 23 There is a first material chamber 30 between them, a water chamber 29 between the first filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com