Grain flotation, dust removal and air drying integrated device

A grain and integrated technology, applied in the direction of grain drying, drying gas arrangement, drying, etc., can solve problems such as unfavorable simultaneous completion, unfavorable grain quality, and threat to food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

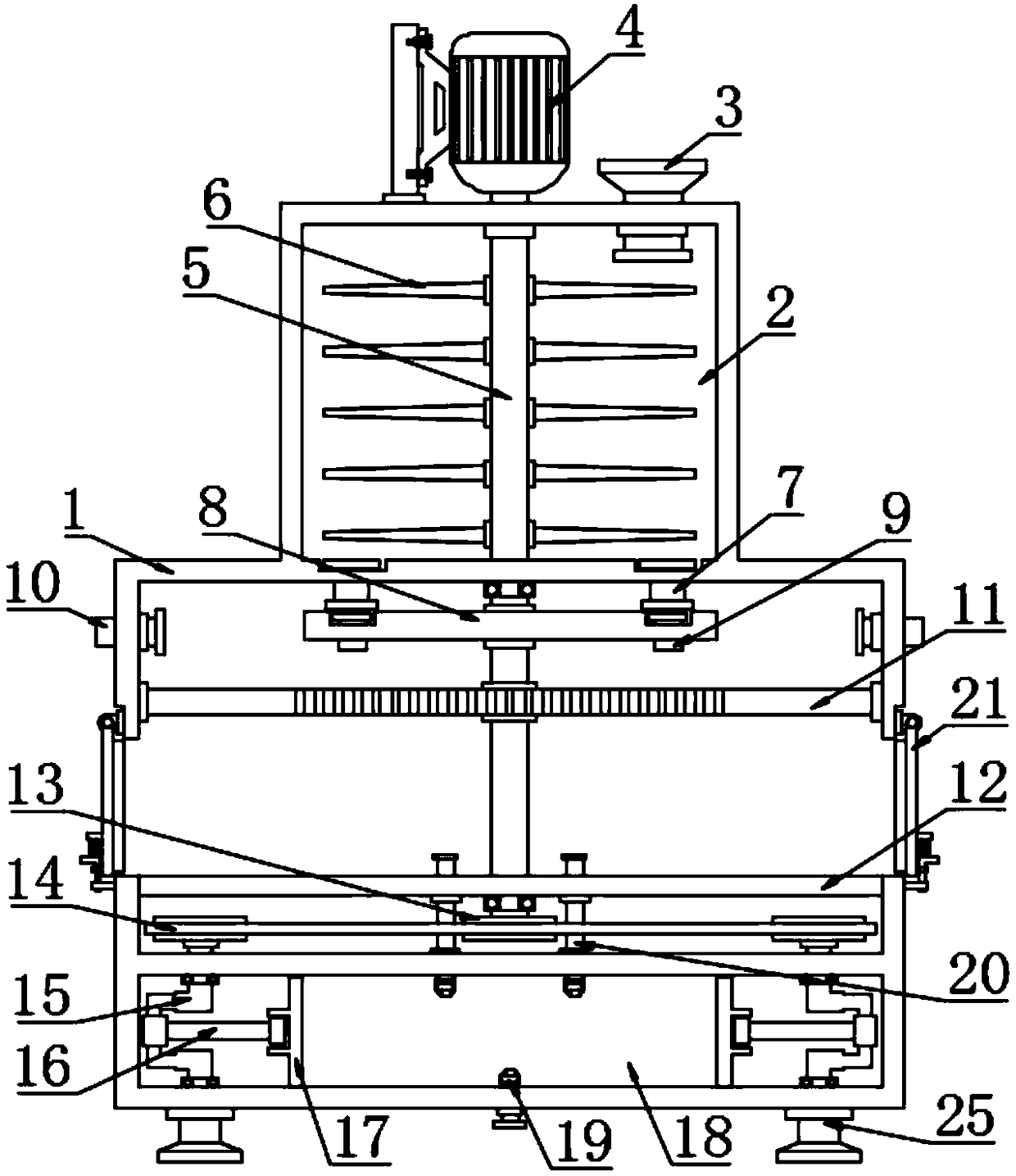

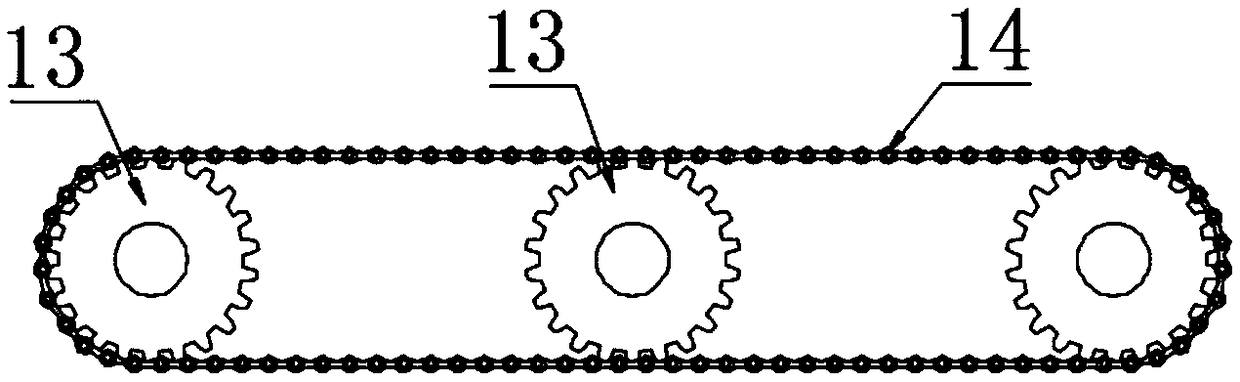

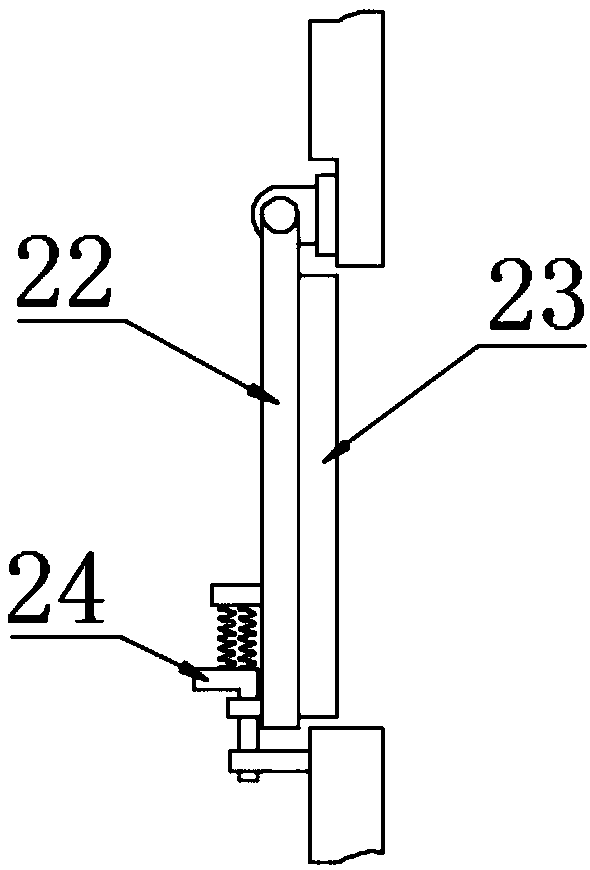

[0024] see Figure 1~4 , in an embodiment of the present invention, a grain flotation, dust removal and air-drying integrated device includes a device body 1, a drive motor 4, a turntable 8, a filter plate 11, a crankshaft 15, a rubber plate 17 and a sealing device 21; the upper part of the device body 1 The material storage tank 2 is set, and the drive motor 4 is arranged in the center of the upper end of the material storage tank 2. The left side of the drive motor 4 is fixedly connected to the motor base, and the motor base bolt is fixedly connected to the vertical plate, and the vertical plate is fixedly connected to the upper end of the material storage tank 2, and the drive motor 4 wires are connected to the power supply and the switch, the lower part of the drive motor 4 is connected to the drive shaft 5 by rotation, the drive shaft 5 passes through the storage barrel 2 and is connected to it in rotation, and the switch is turned on so that the drive motor 4 is energized...

Embodiment 2

[0028] see Figure 1~4, in an embodiment of the present invention, a grain flotation, dust removal and air-drying integrated device includes a device body 1, a drive motor 4, a turntable 8, a filter plate 11, a crankshaft 15, a rubber plate 17 and a sealing device 21; the upper part of the device body 1 The material storage tank 2 is set, and the drive motor 4 is arranged in the center of the upper end of the material storage tank 2. The left side of the drive motor 4 is fixedly connected to the motor base, and the motor base bolt is fixedly connected to the vertical plate, and the vertical plate is fixedly connected to the upper end of the material storage tank 2, and the drive motor 4 wires are connected to the power supply and the switch, the lower part of the drive motor 4 is connected to the drive shaft 5 by rotation, the drive shaft 5 passes through the storage barrel 2 and is connected to it in rotation, and the switch is turned on so that the drive motor 4 is energized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com