A laser tailor welding production line

A laser tailoring welding and production line technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of falling, large area of feeding module, low production efficiency, etc., achieve process concentration, reduce The effect of increasing the time of falling and rising multiple times and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

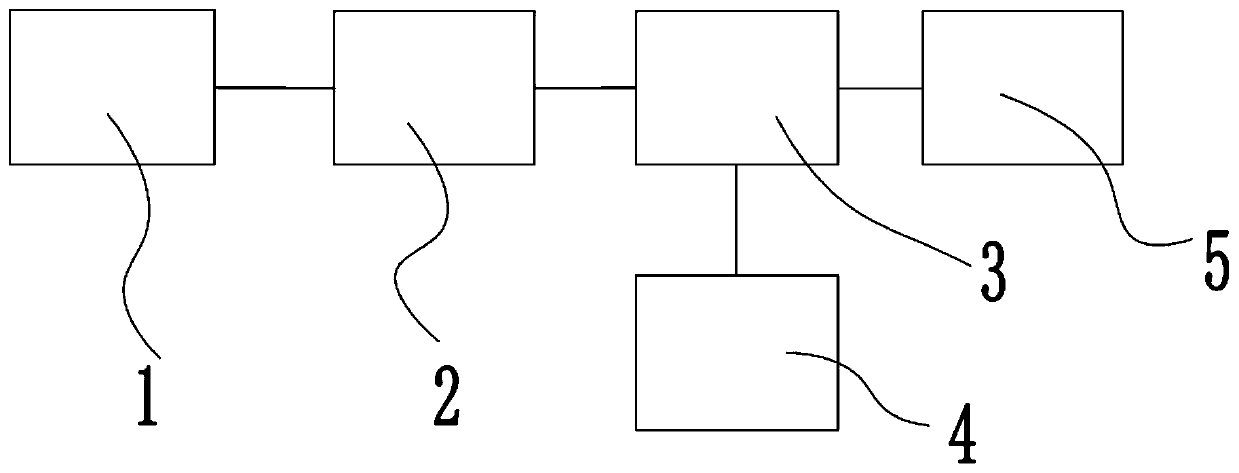

[0030] Refer below Figure 1 to Figure 6 To further explain this application, such as figure 1 The tailor-made laser welding production line shown includes a feeding device 1 , a tailor-made laser welding device 2 , a blanking device 3 , a sampling and discharging device 4 and a stacking device 5 .

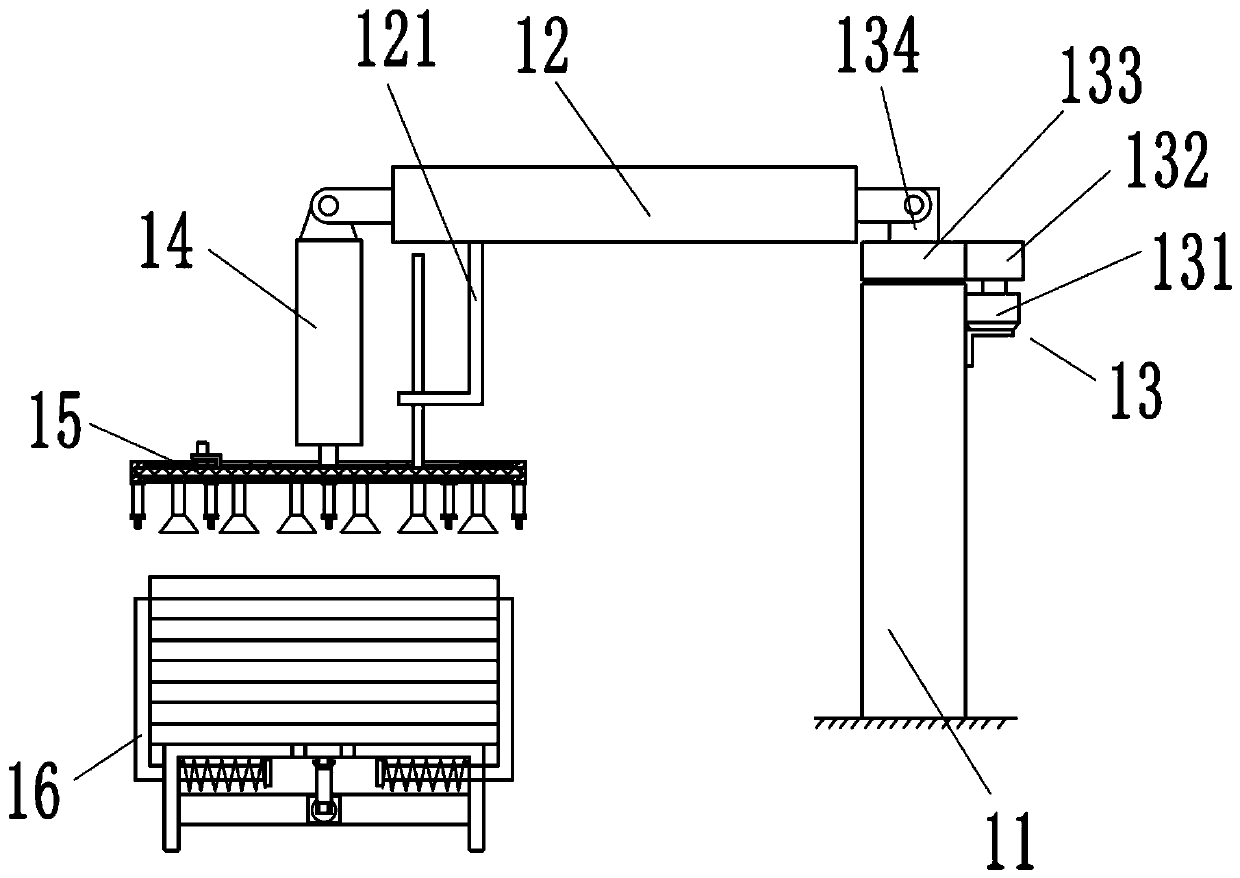

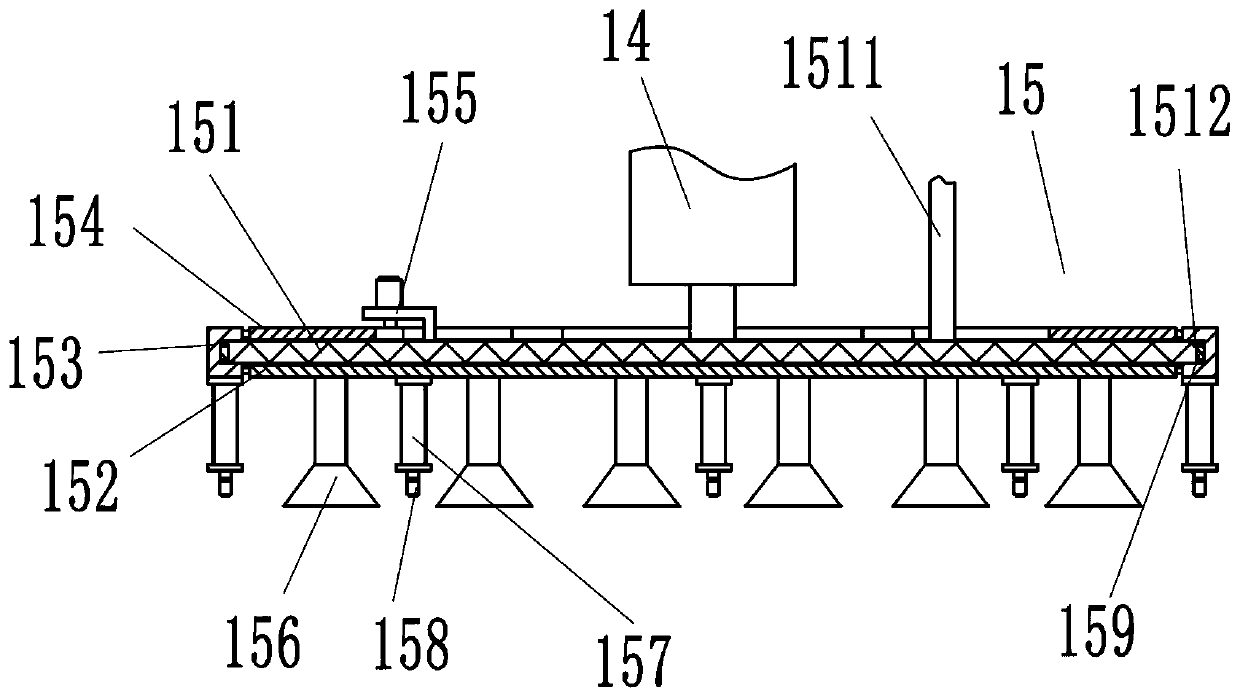

[0031] Such as figure 2 , image 3 and Figure 4 As shown, the feeding device 1 includes a column 11 and a material receiving frame 16, the material receiving frame 16 is used to place stacked plates, the top of the column 11 is provided with a rotating truss 12, and the rotating truss 12 Rotate around the axis of the column 11 under the action of the first rotary drive device 13 of the feeding device 1, a lifting cylinder 14 is provided on the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com