Mechanical hand for engineering

A manipulator and engineering technology, applied in manipulators, manufacturing tools, chucks, etc., can solve the problems of people climbing on the machine, danger, parts flying to the machine, etc., to facilitate replacement and maintenance, prolong service life, and prevent falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

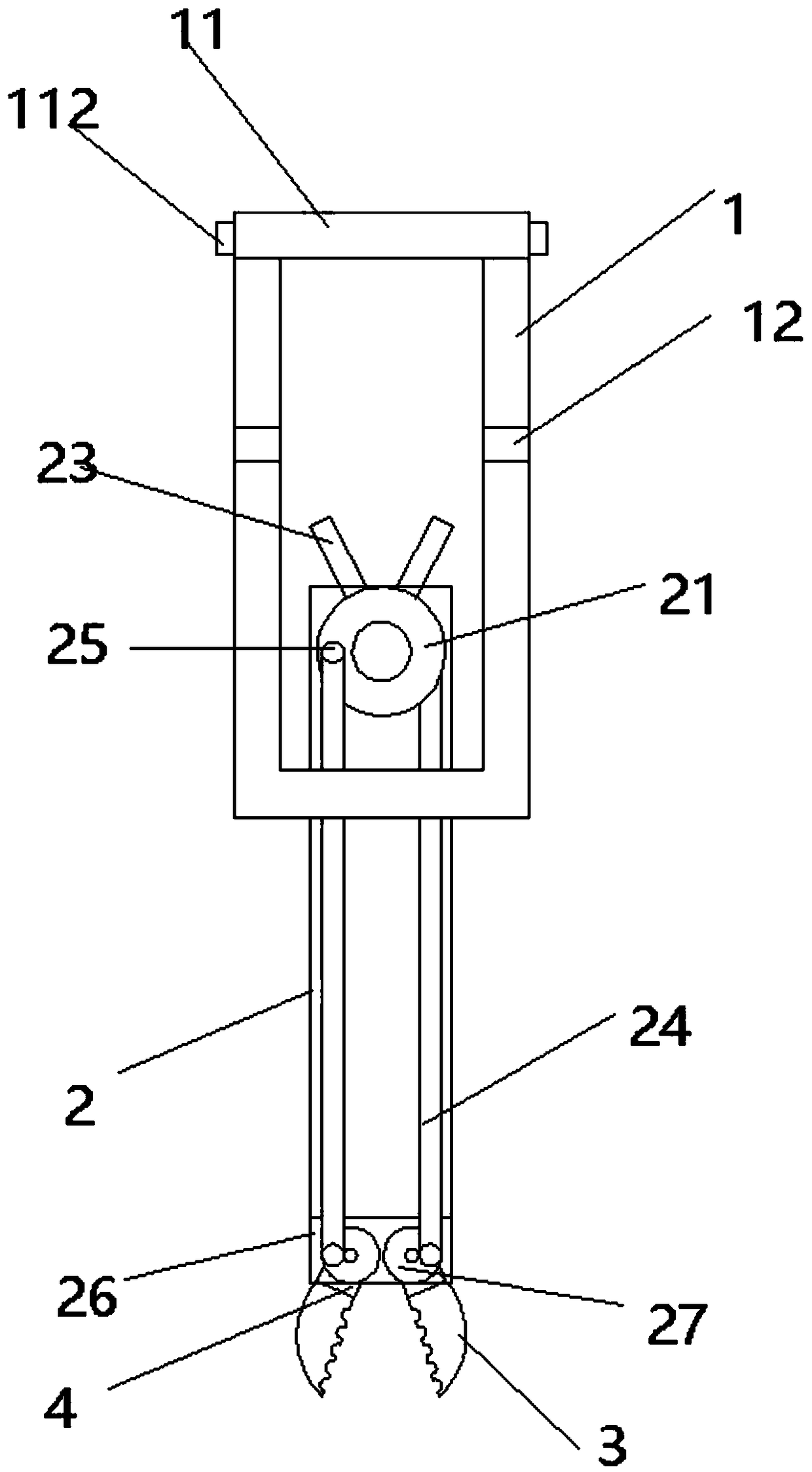

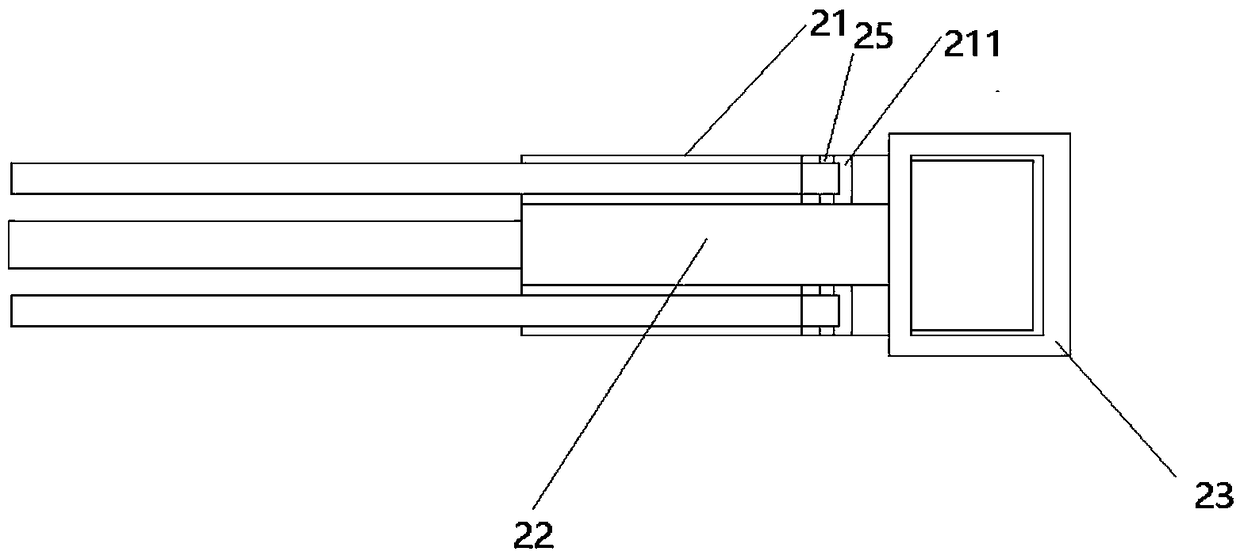

[0024] An engineering manipulator, comprising: a collar 1, a mechanical arm 2 and a mechanical finger 3, such as figure 1 As shown, the upper end of the collar 1 is provided with a collar 11, the lower end of the collar 11 is slidingly connected with the collar 1, the collar shaft 12 is arranged in the middle of the collar 1, and the collar 1 at the upper and lower ends is connected through the collar shaft 12. The lower end of the ring 1 is rotationally connected with the mechanical arm 2, and a handle shaft is provided on the inner side of the upper end of the mechanical arm 2, and the handle shaft includes an outer shaft 21 and an inner shaft 22, such as image 3 As shown, an inner shaft 22 is arranged in the middle of the outer shaft 21, and the outer shaft 21 is connected to the inner shaft 22 by passing the rivet through the hole in the middle of the outer shaft 21 and the inner shaft 22. The side is provided with connection port 211, and connection port 211 is provided ...

Embodiment 2

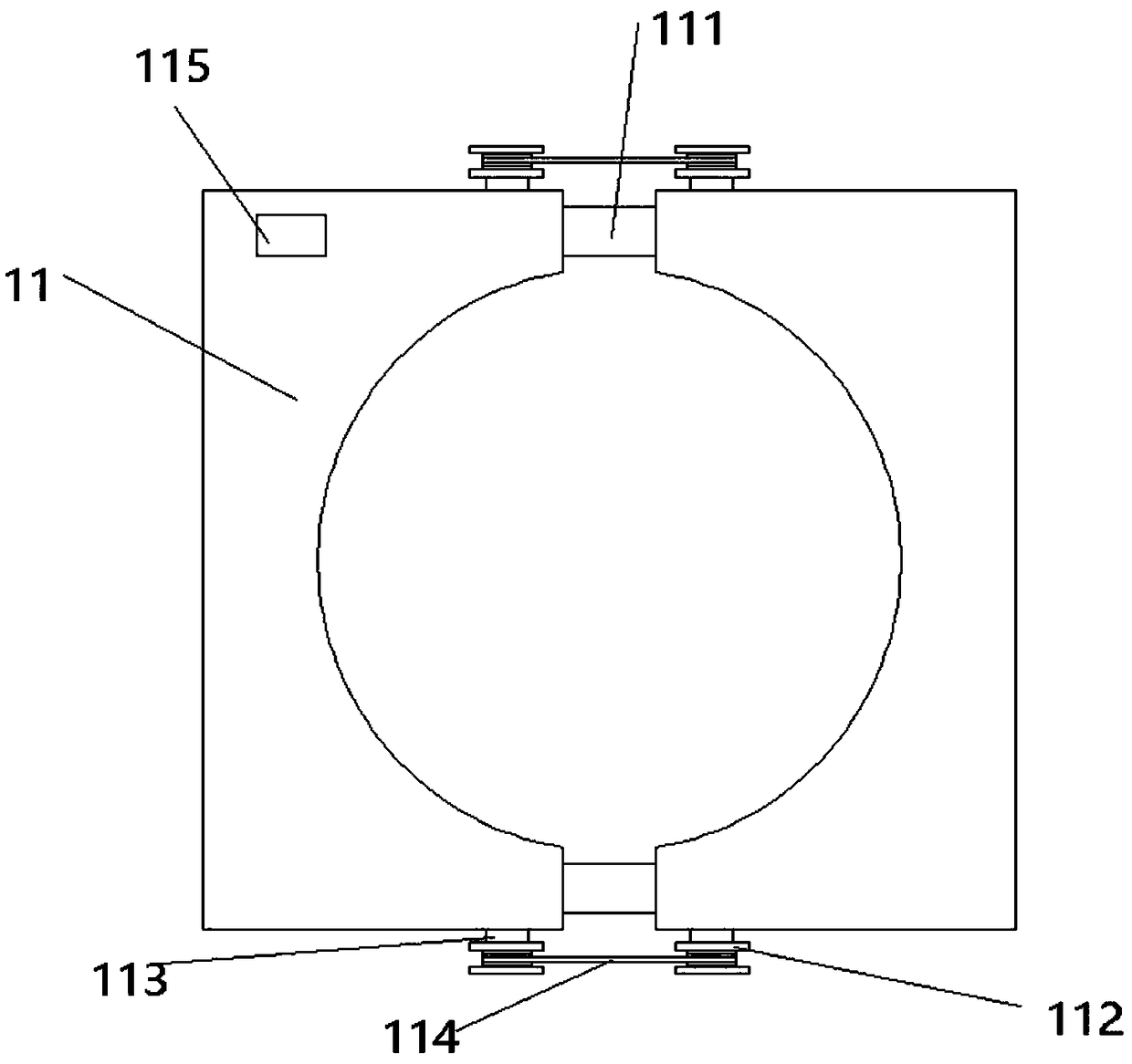

[0026] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the inside of the left and right ends of the sleeves 11 is semicircular, the sleeves 11 at both ends are slidably connected by the sleeve connecting rod 111, the upper and lower ends of the sleeve 11 are provided with a sleeve connecting shaft 112, and the sleeve connecting shaft 112 passes through the sleeve. The connecting column 113 is fixedly connected with the socket motor in the socket 11, the socket connecting shafts 112 at the left and right ends are connected by a connecting belt 114, and a socket controller 115 is provided on the socket 11 upper end.

[0027] When in use, separate the sleeves 11 at both ends, put the arm into the circular groove inside the sleeve 11, press the sleeve controller 115 to control the motor in the sleeve 11 to rotate, so that the sleeves 11 on both sides are closed and wrapped The motor in the rear pocket 11 of the arm stops working, and when no...

Embodiment 3

[0029] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the lower end of the finger shaft connection block 4 is provided with a finger shaft connection hole 41, the finger shaft connection hole 41 is an internal thread structure, the upper end of the mechanical finger 3 is fixed with a mechanical finger cover 38, and the left and right sides of the mechanical finger cover 38 are fixed with telescopic tubes 36, Telescopic tube 36 outside is provided with telescopic rod 31, and telescopic rod 31 right side is provided with telescopic block 35, and telescopic block 35 is connected with telescopic tube 36 by spring 37, and telescopic rod 31 outside is provided with screw cap 32, and screw cap 32 right side is fixed with The screw rod 33 is provided with a screw connection block 34, the left side of the screw rod 33 passes through the telescopic rod 31 and is fixedly connected with the screw cap 32, and the right side of the screw rod 33 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com