Square-bale hay palletizing device

A stacking device and hay technology, applied in the field of square bale hay stacking devices, can solve the problems of low stacking stability, low stacking efficiency of forklifts, high labor intensity, etc., and achieve convenient operation, simple structure, and increased stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

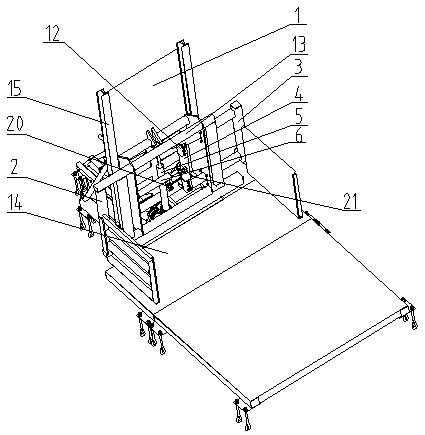

[0028] In the above specific embodiment, I-shaped steel lifting guide rails 15 are respectively provided on both sides of the folder guide bracket 1 , and rectangular steel sliders matched with the lifting guide rails 15 are respectively welded on both sides of the first folder structure 2 .

[0029] There are four sliders, and a slider is respectively provided at the top and the bottom of both sides of the first folder structure 2 .

[0030] A channel steel cladding guide rail 13 matched with the second cladding structure 3 is provided on the cladding guide bracket 1 .

[0031] Guide grooves are provided on the stacking support 10 .

[0032] A rectangular steel feeding guide rail 24 matched with the feeding rod 8 is provided on the feeding bracket 17 .

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is:

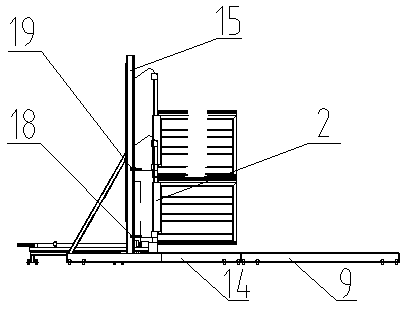

[0035] A first lifting travel switch 18 is provided at the lower part of the lifting guide rail 15 close to the first folder structure 2, and a second lifting travel switch 19 is provided at the upper part.

[0036] A first clamping travel switch 20 is provided in the middle of the clamping guide rail 13 , and a second clamping travel switch 21 is provided at a position close to the second clamping mechanism 3 on the clamping guide rail 13 .

[0037] A first push-stack travel switch 22 is provided in the middle of the guide groove, and a second push-stack travel switch 23 is provided on the guide groove near one end of the folder guide bracket 1 .

[0038] A first feeding stroke switch 25 is arranged in the middle part of the feeding guide rail 24 , and a second feeding stroke switch 26 is arranged on the feeding guide rail near the primary collecting platform 14 .

[0039] Through the control of the travel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com