High-speed stacking system with pre-tensioning device

A palletizing system, high-speed technology, applied in the direction of object stacking, object destacking, conveyor objects, etc., can solve the problems of high work intensity, poor matching, poor position accuracy, etc., to speed up the palletizing speed, improve Accuracy, increased efficiency and the effect of palletizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

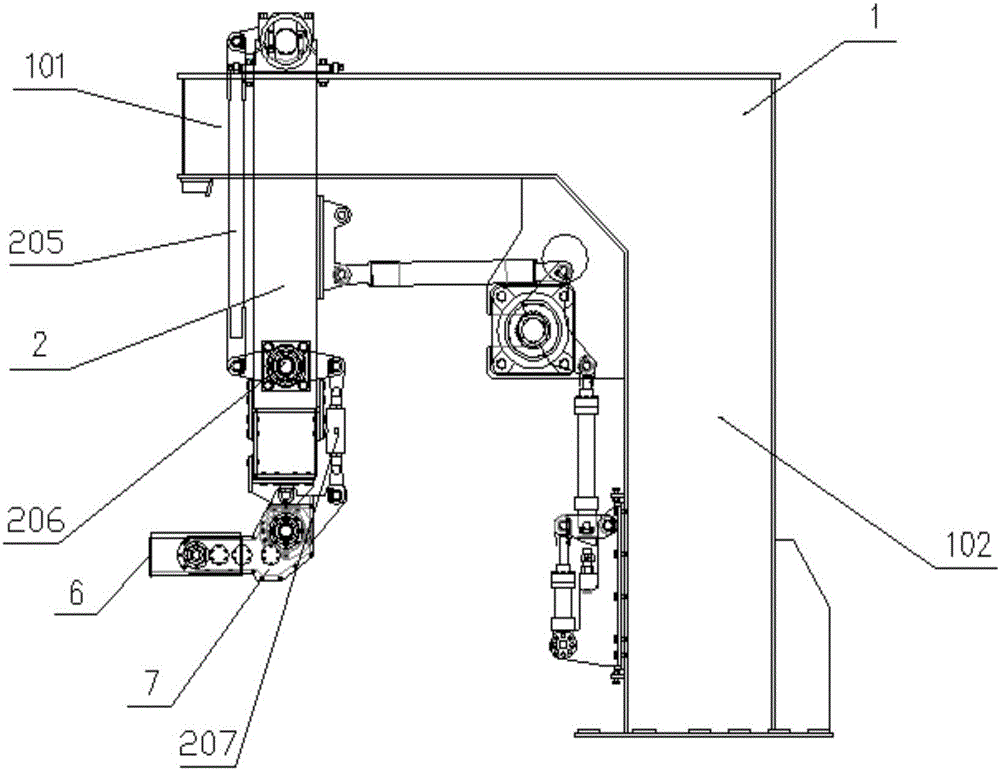

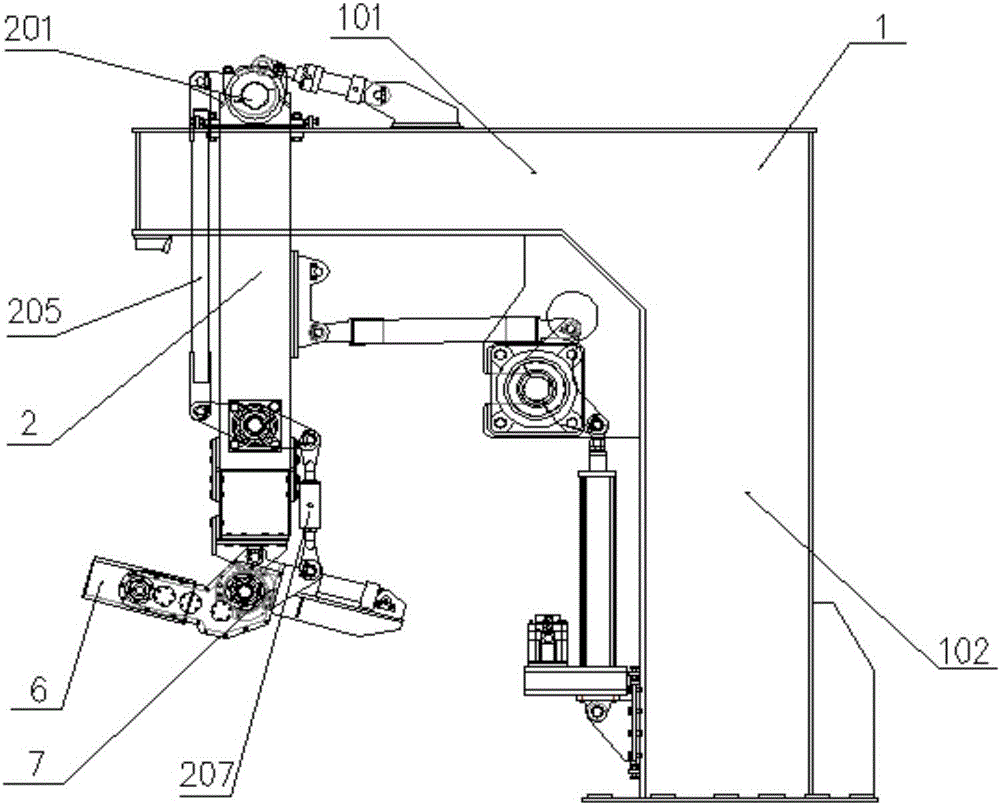

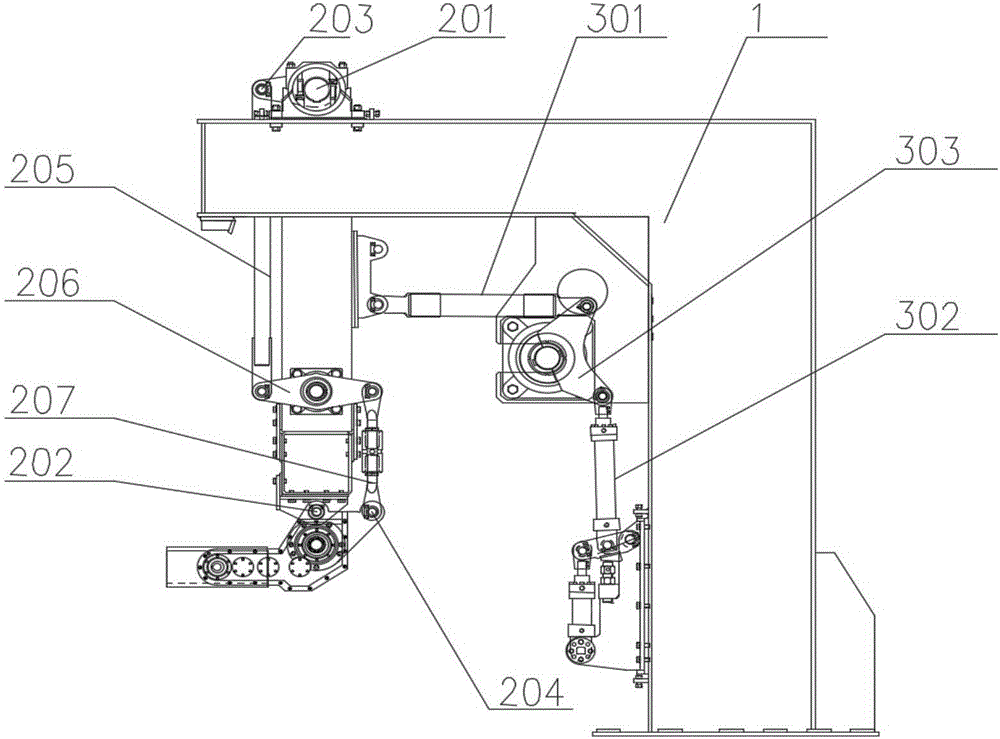

[0058] The high-speed palletizing system of the present embodiment comprises a frame 1, a boom 2, a driving device, a wrist 7 and a turning permanent magnet 6; the frame 1 includes a horizontal section 101 and a vertical section 102, and the frame 1 The rear end of the horizontal section 101 is connected to the top of the vertical section 102, and the front end of the horizontal section 101 of the frame 1 is hinged to the upper end of the boom 2;

[0059] The driving device is hinged with the front side of the vertical section 102 of the frame 1 and the boom 2 respectively; mechanism, the front end of the wrist 7 is provided with an overturning permanent magnet 6; the bottom end of the overturning permanent magnet 6 is provided with a translation guide tooth plate; the vertical section 102 of the frame 1 is provided with a part or All self-weight and load pre-tensioning devices;

[0060] The wrist 7 includes a connection plate arranged at the bottom of the boom 2, and two sid...

Embodiment 2

[0068] Such as Figure 5 As shown, the pretensioning device in this embodiment includes a balance mechanism whose two ends are respectively hinged to the frame and the boom, and a balance adjustment mechanism for adjusting the balance force of the balance mechanism;

[0069] The balance mechanism includes a cylinder 501 and an air bag 510 communicated with the cylinder, and the balance adjustment mechanism includes an air source 516, an air source processing element 512 for communicating with the air source 516 and the air bag 510, and an air source processing element 512 arranged on the air bag. Barometer 511 on 510;

[0070] The air cylinder 501 is installed between the boom 2 and the frame body 1, and supports the dead weight of the boom 2 during the movement of the boom 2.

[0071] The air supply system includes an air source 516, an air bag 510, an air pressure gauge 511, an air source treatment element 512, a welded steel pipe 503, and a ball valve 513. The three air s...

Embodiment 3

[0077] The flip magnet described in this embodiment is provided with a magnetic force control system, and the magnetic force control system includes a sensor for detecting the position of the electromagnet and a control device for controlling the magnetic force of the electromagnet; output control information to adjust the magnetic force of the flipping electromagnet;

[0078] The method for the control device to output control information to adjust the magnetic force of the flip electromagnet according to the received position information of the flip electromagnet detected by the sensor is: when it is detected that the flip electromagnet flips to the first phase, the control device The magnetic force of the control electromagnet is located in the first interval; when it is detected that the flipping electromagnet is flipped to another phase, the control device controls the magnetic force of the electromagnet to be located in the second interval.

[0079] When the flipping ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com