Safe pole climbing lifting mechanism for aloft work

A lifting mechanism and high-altitude operation technology, applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of low safety and high probability of safety accidents, and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

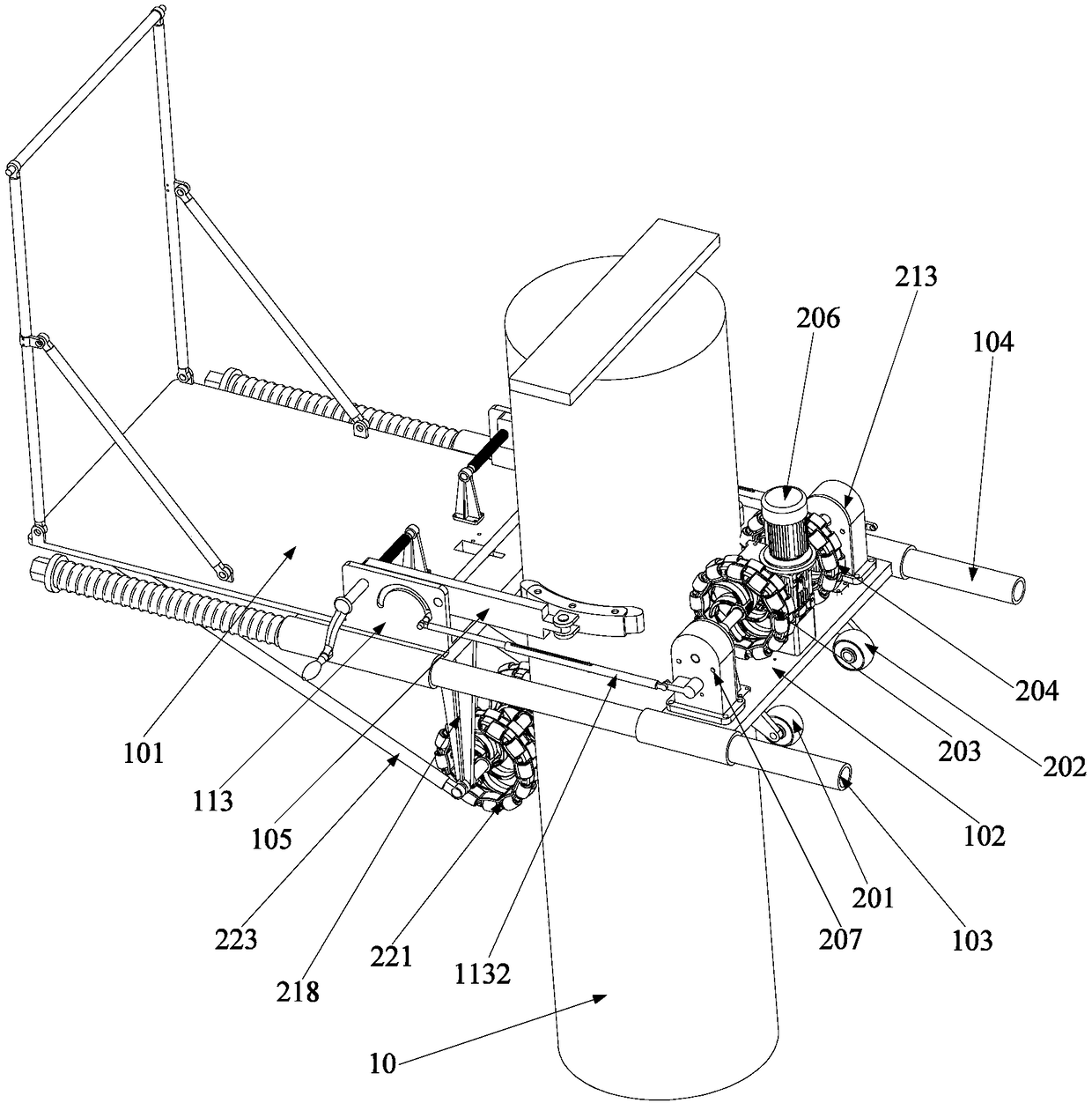

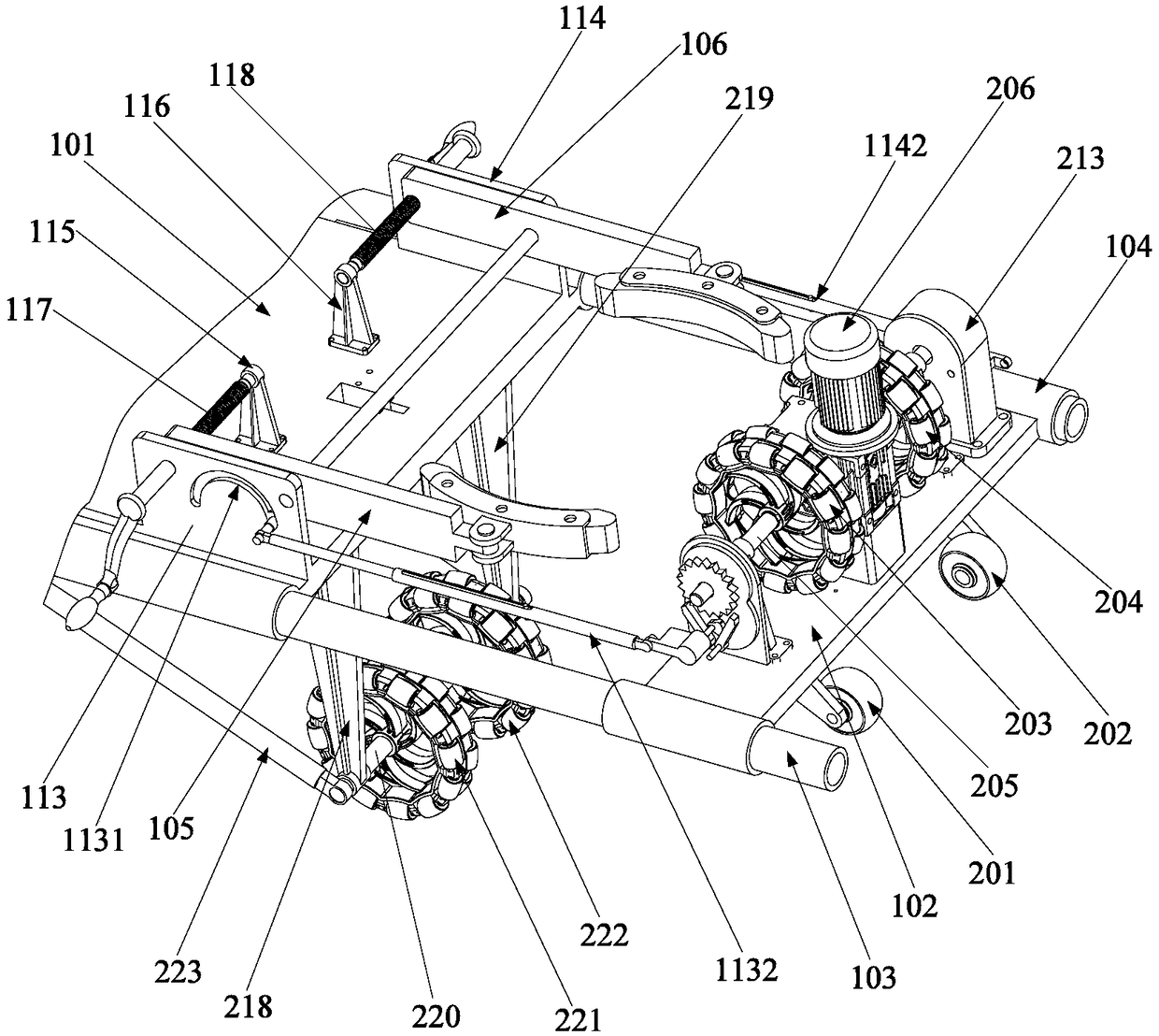

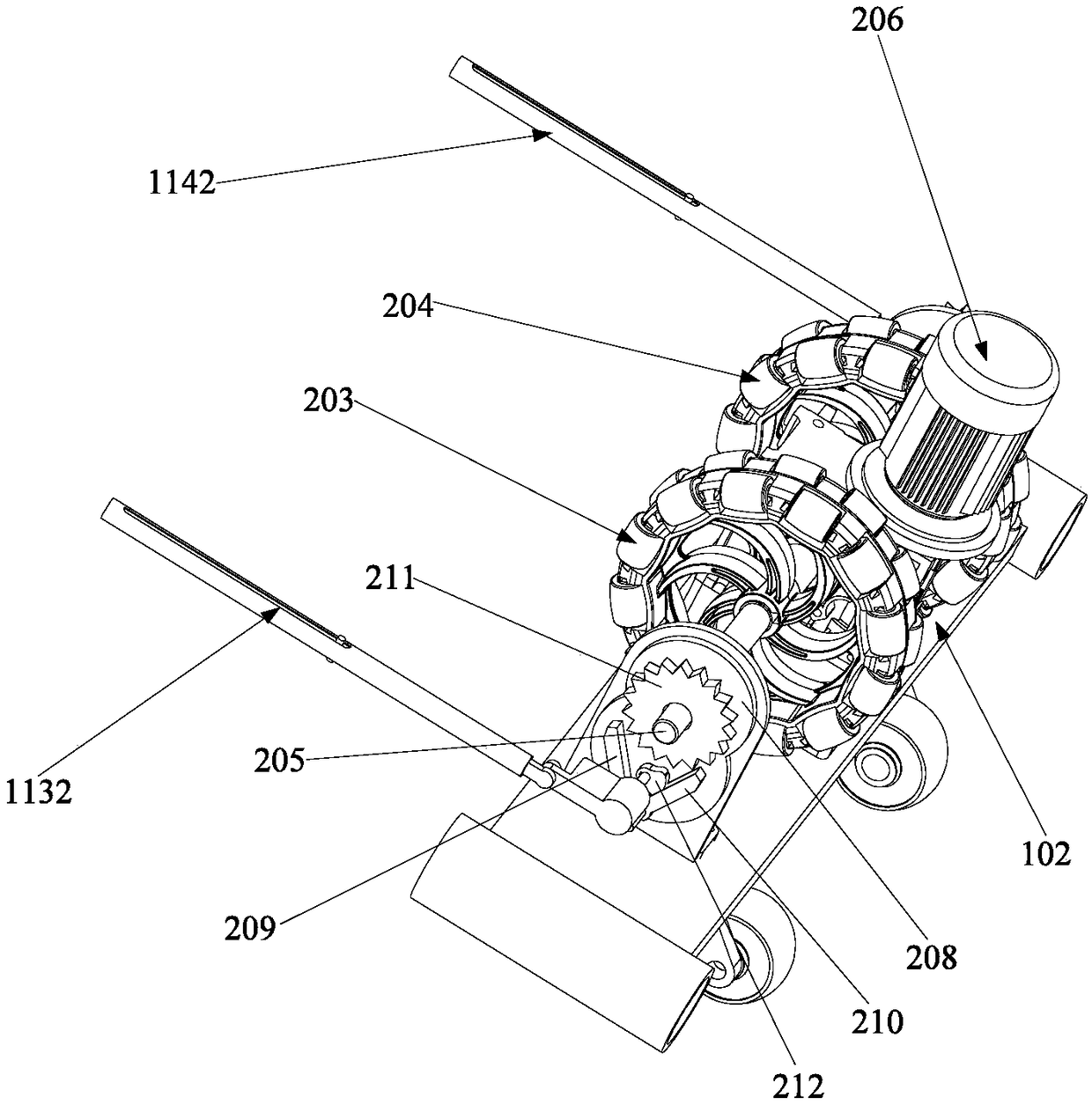

[0020] see Figure 1-4 , the safety pole climbing mechanism for working at heights includes a first support plate 101, a second support plate 102, a first connecting rod 103, a second connecting rod 104, a first moving rod 105, a second moving rod 106, a first A shaft bracket 201, a second shaft bracket 202, a first lifting rotating wheel 203, a second lifting rotating wheel 204, a lifting motor 206, a first braking mechanism and a second braking mechanism.

[0021] The second supporting board 102 is spaced apart from the first supporting board 101 . Further, the second support plate 102 is at the same level as the first support plate 101 , and the second support plate 102 can be moved relative to the first support plate 101 .

[0022] The first connecting rod 103 passes through one side end of the first support plate 101 and the second support plate 102 . Specifically, one side end of the first supporting plate 101 is provided with a first through hole, one side end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com