Combined support beam reaction force loading device

A technology of counter-loading and supporting beams, which is applied in construction, foundation structure tests, foundation structure engineering, etc., can solve the problems of large size, unfavorable rapid reuse, low safety of on-site construction, etc., and achieve high construction safety , Construction difficulty and low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

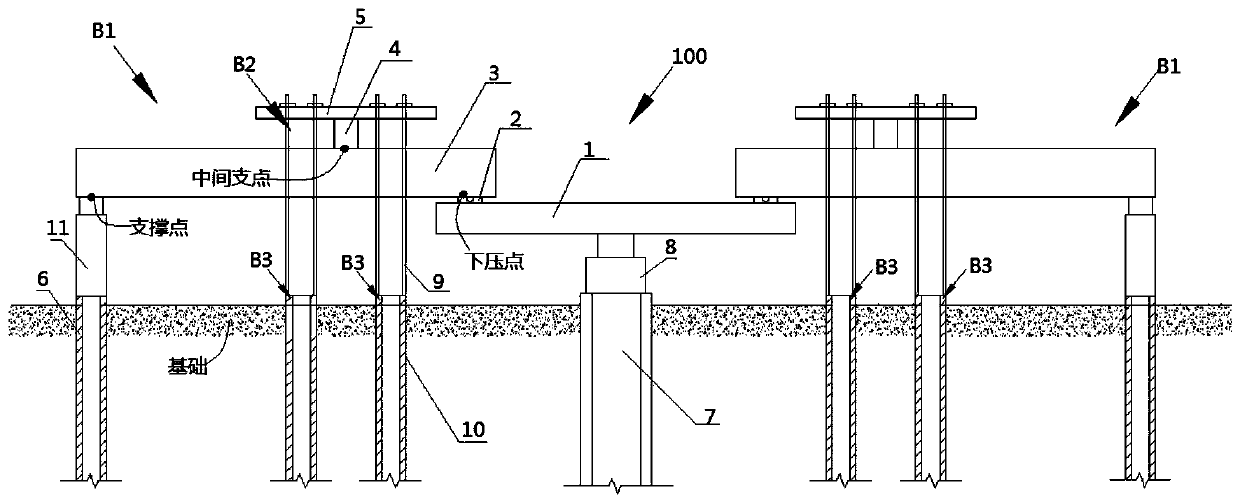

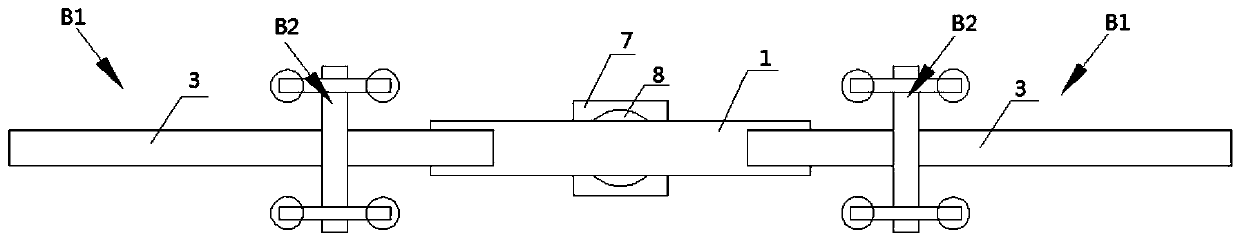

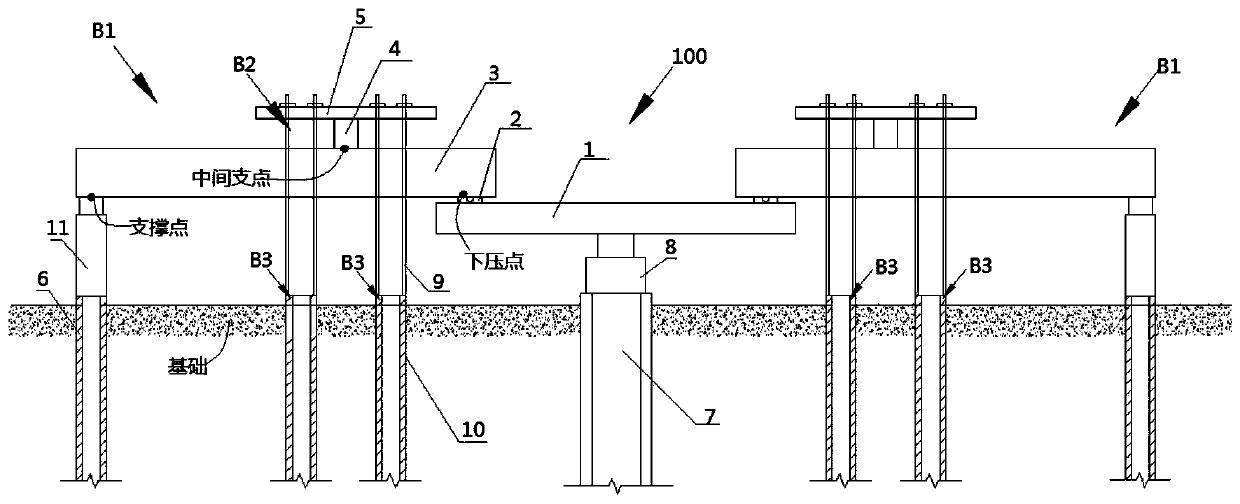

[0044] figure 1 A structural schematic diagram showing an embodiment of the structure of the combined support beam reaction force loading device 100 in the embodiment of the present invention (in the figure, the target test pile 7 and the foundation on which it is set are additionally shown by a dotted line); figure 2 for figure 1 top view.

[0045] Please refer to figure 1 , figure 2 , the combined support beam reaction force loading device 100 in this embodiment includes a lifting drive device 8, a target stress bearing beam 1 and a plurality of downward pressure structures B1; the target stress bearing beam 1 is arranged along the horizontal direction, and the target stress bearing beam The beam 1 is arranged along the horizontal direction, and the target stress bearing beam 1 is arranged to be pressed downward on the target test pile 7, and expands in the horizontal direction, and the horizontal length of the target stress bearing beam 1 is greater than the target tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com