Suction cup

A technology of suction cups and adsorption parts, which is applied in the direction of suction cups, connecting components, mechanical equipment, etc., can solve the problems of discontinuous pressure, reduced vacuum degree, and poor sealing performance, so as to improve the overall structural strength, enhance the mounting capacity, and enhance the sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

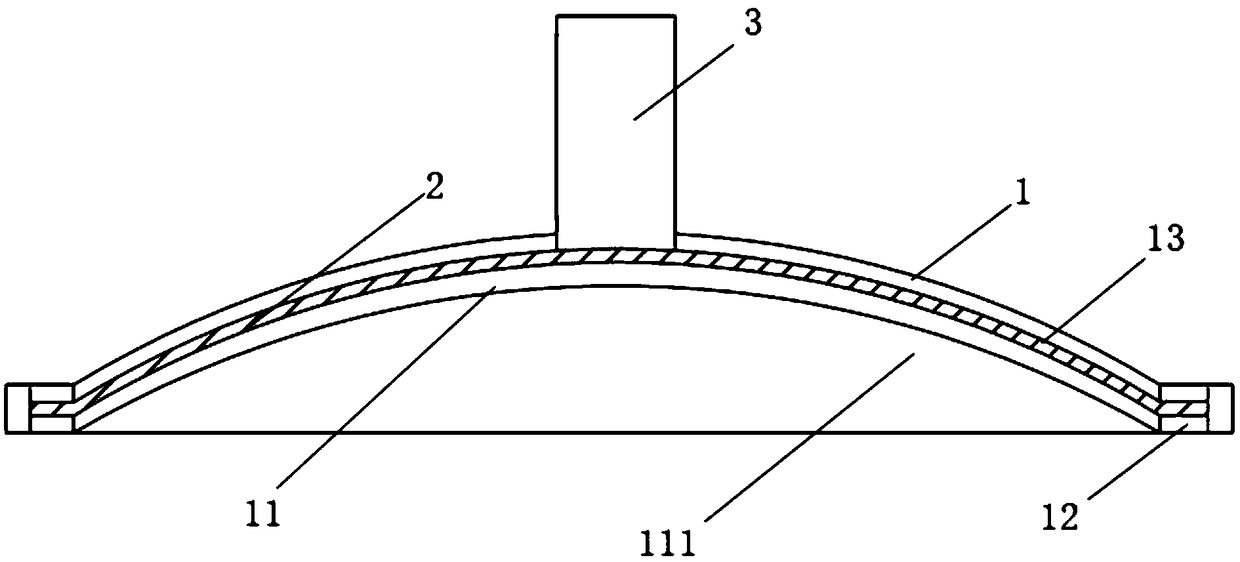

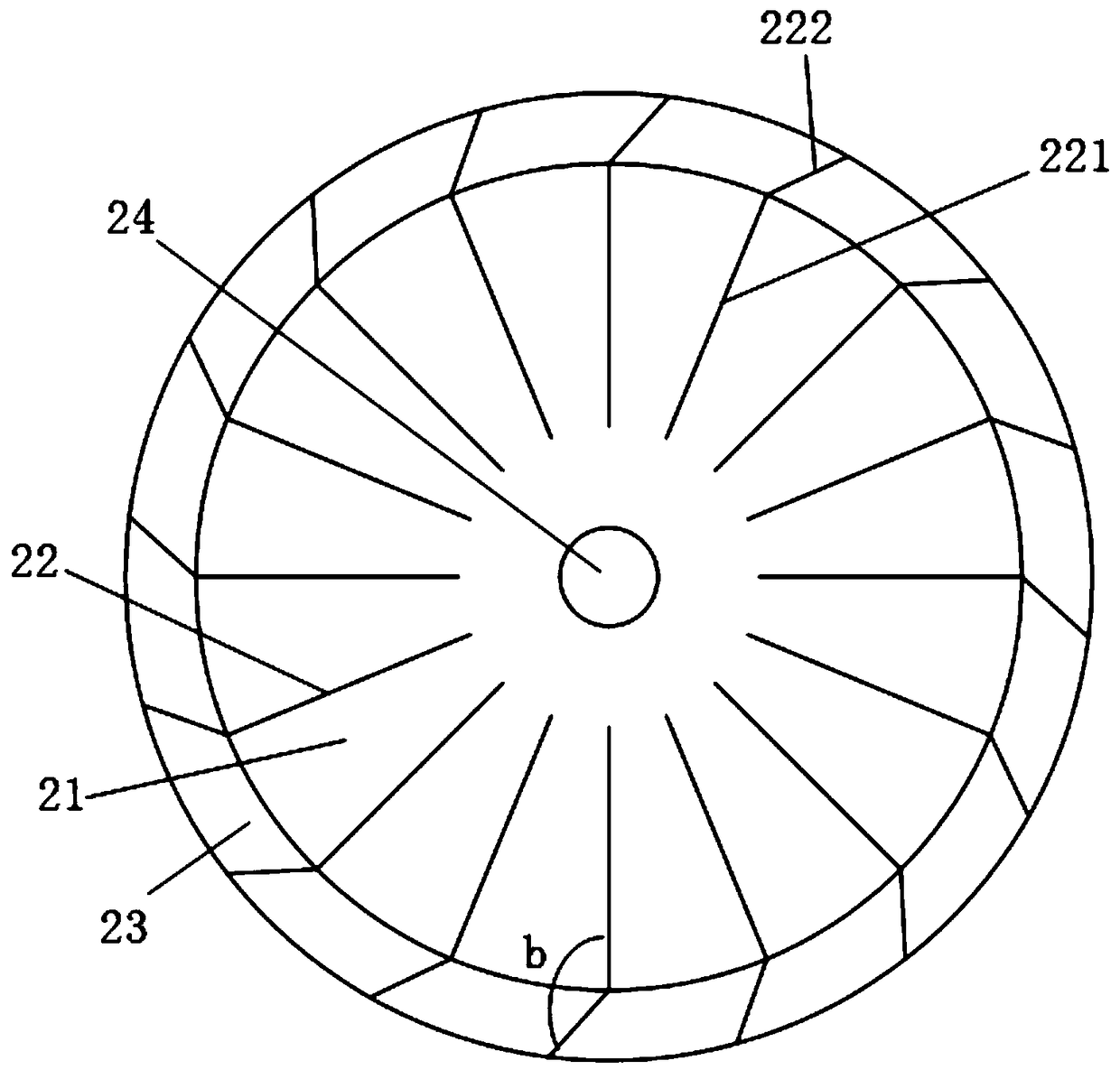

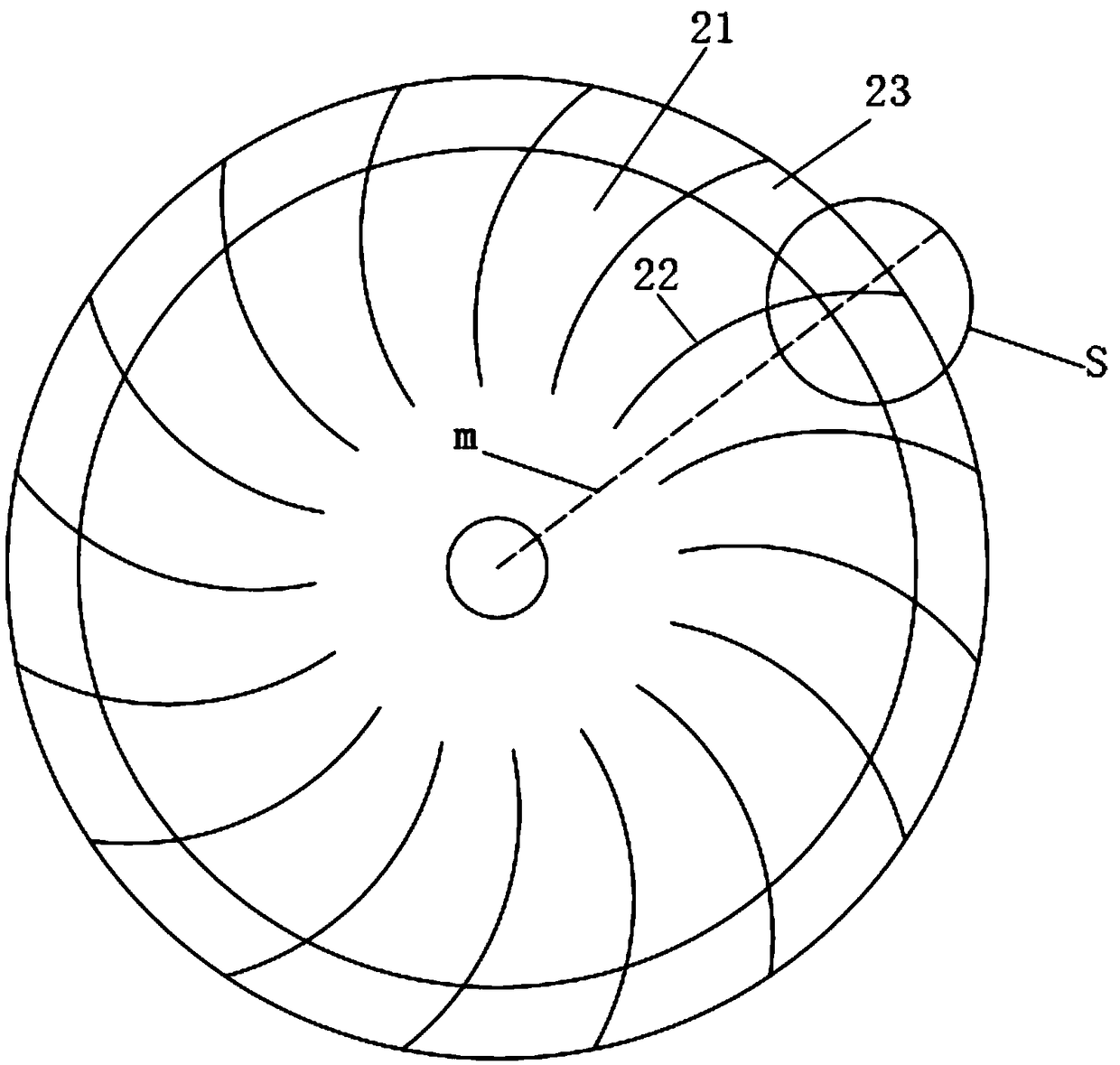

[0022] Such as Figure 1 to Figure 4 As shown, a suction cup in this embodiment includes an absorber 1 and an elastic element 2, the absorber 1 is made of soft material, the absorber 1 includes a main body 11 and a skirt portion 12, and the skirt portion 12 surrounds the main body 11 set up. The main body 11 has a recessed portion 111, the skirt portion 12 is located on the edge of the recessed portion 111, the elastic element 2 is arranged on the main body 11 and attached to the main body, and the elastic element 2 is continuous on the main body. The elastic element 2 includes an elastic body 21, a plurality of elastic bodies 21 are arranged at intervals, and there is a slit 22 between adjacent elastic bodies. One end of the elastic body 21 is provided with a pressing plate 23...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap