Turbo-shaft engine self-adaptive component-level simulation model construction method

A turboshaft engine and simulation model technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of model mismatch, individual differences of turboshaft engines, etc., to reduce model errors, high model accuracy, Output with high tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

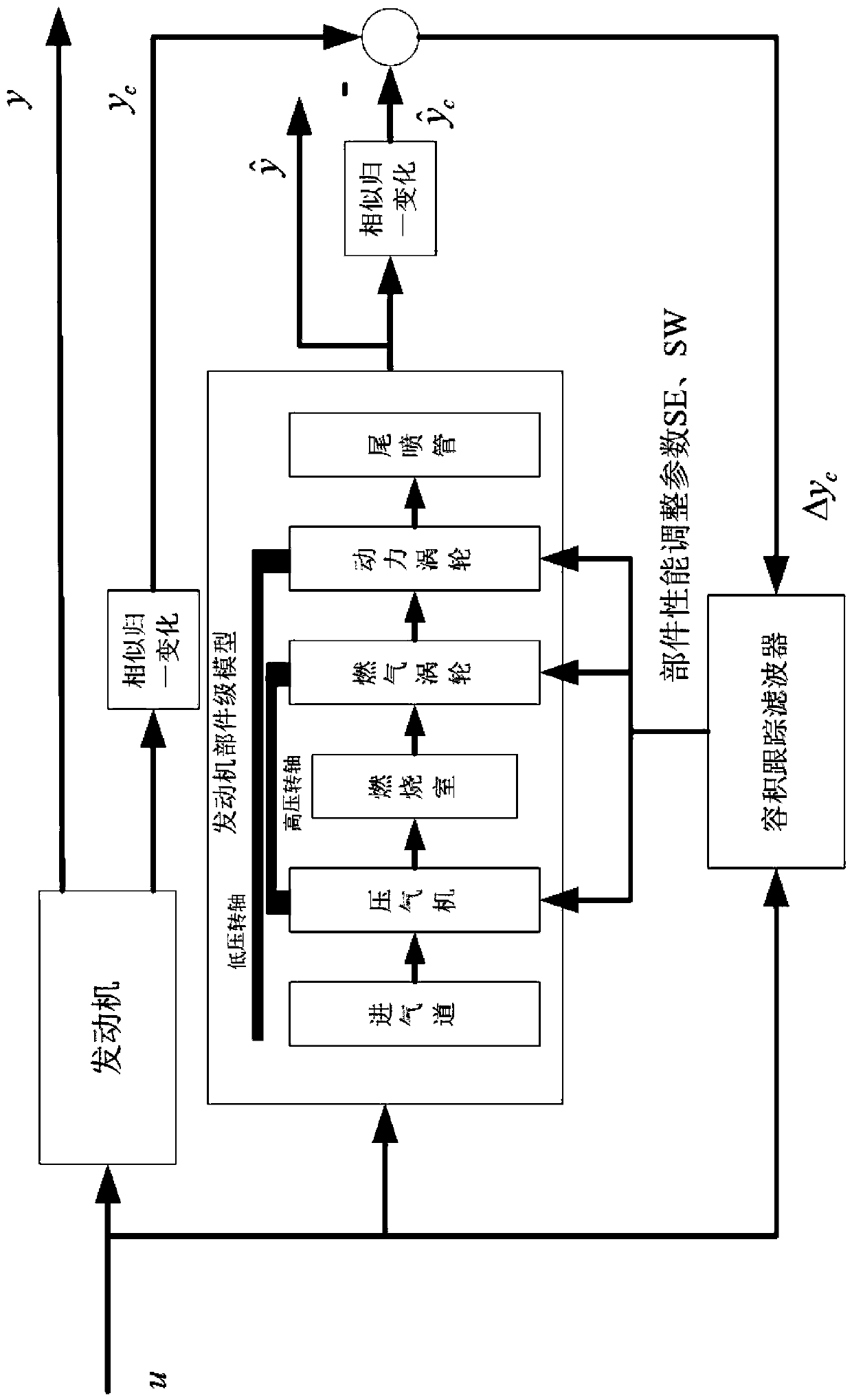

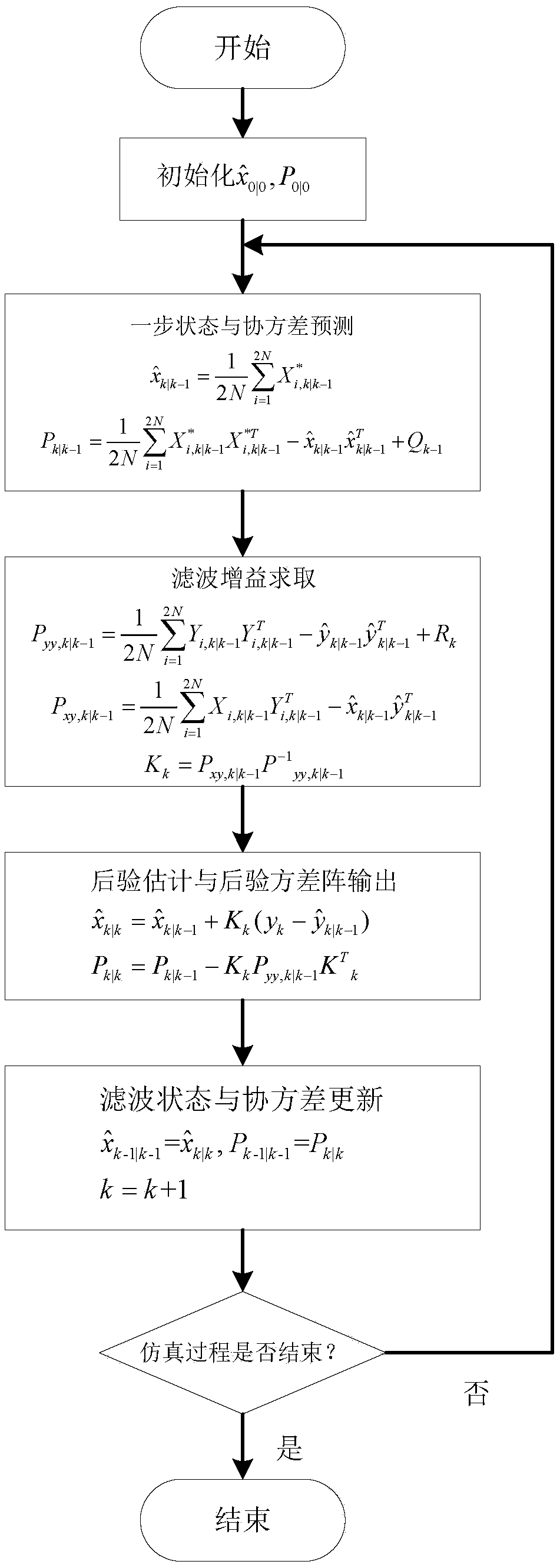

[0045] In this embodiment, the construction of an adaptive component-level simulation model of a certain type of turboshaft engine is taken as an example. figure 2 is the schematic diagram of the turboshaft engine adaptive component-level simulation model, and the establishment of the simulation model includes the following steps:

[0046] Step A, according to the aerodynamic thermodynamic characteristics of each component of the turboshaft engine, obtain the parameters of each working section of the turbofan engine, and establish a nonlinear component-level dynamic general model of the state of the turboshaft engine above idle; the detailed steps are as follows:

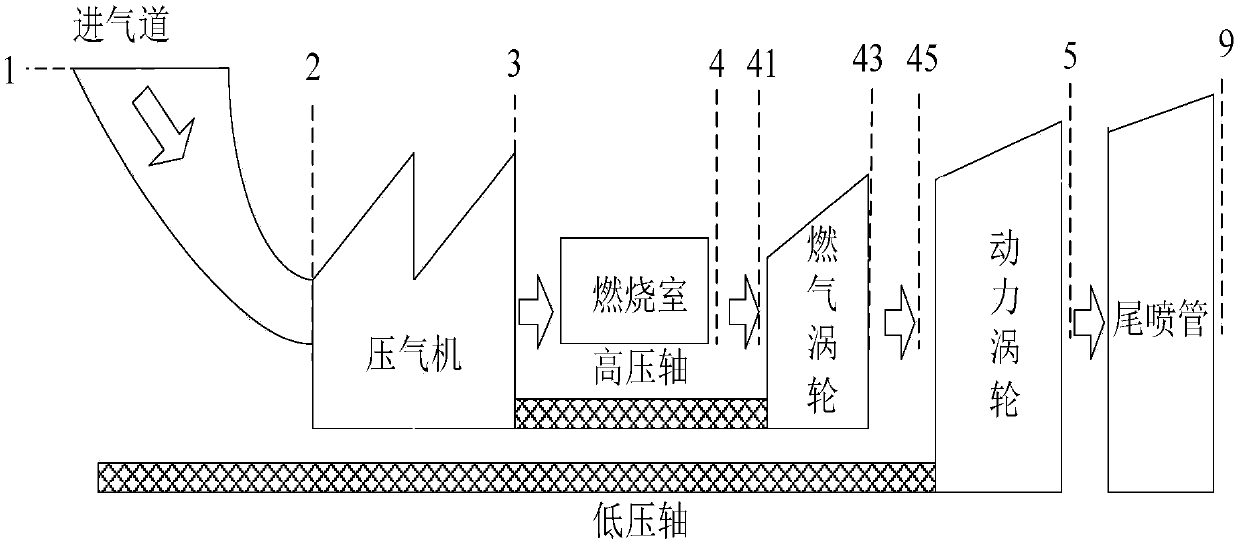

[0047] Step A1, the components and working sections of a certain type of turboshaft engine are as follows figure 1 As shown, the engine component-level model is established according to the characteristics of the turboshaft engine components, design point parameters and test data, including the intake port, compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com