Self-locking power connector

A power connector, self-locking technology, applied in the parts, connections, contact parts of the connecting device, etc., can solve the problems of difficult connection, low efficiency, and difficult to popularize and apply, and achieve the effect of improving the efficiency of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

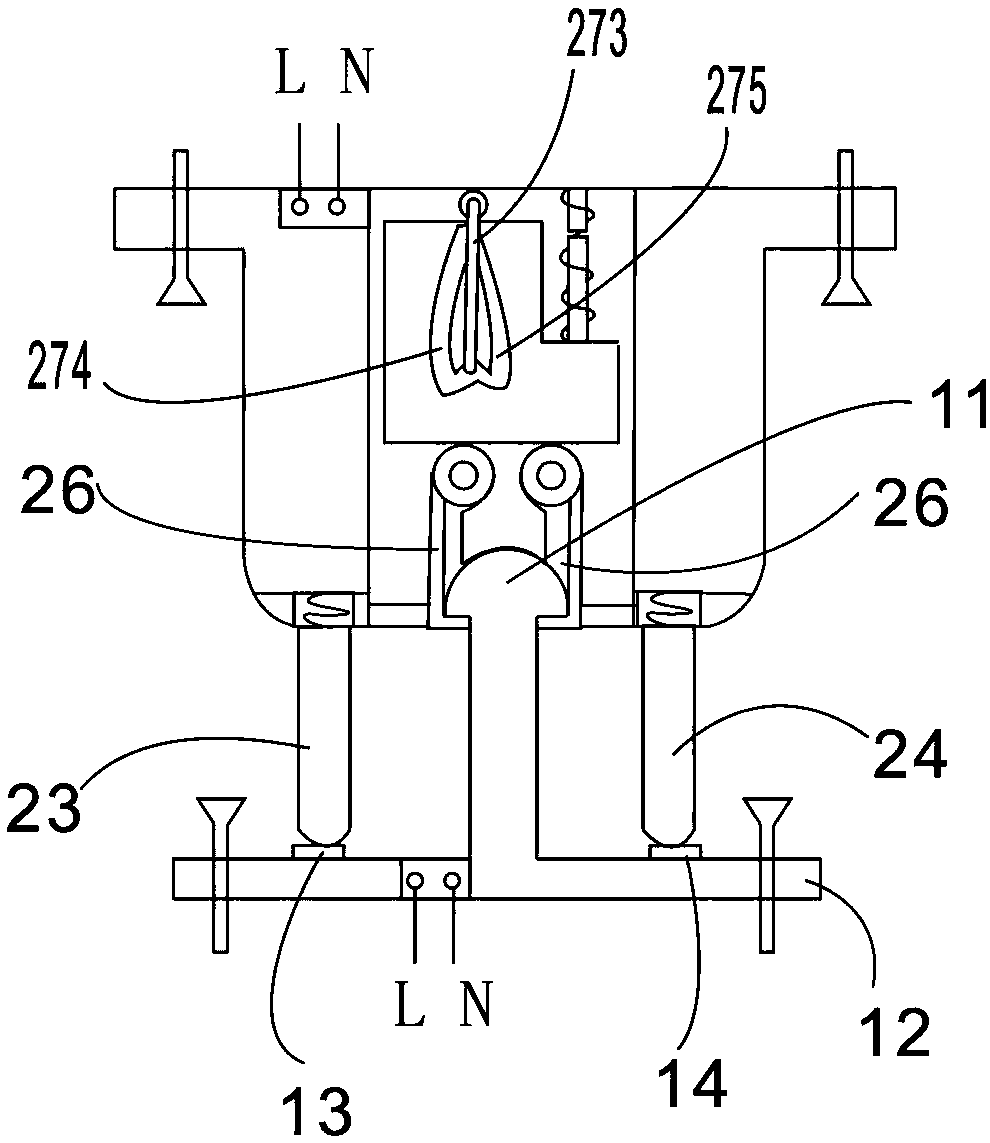

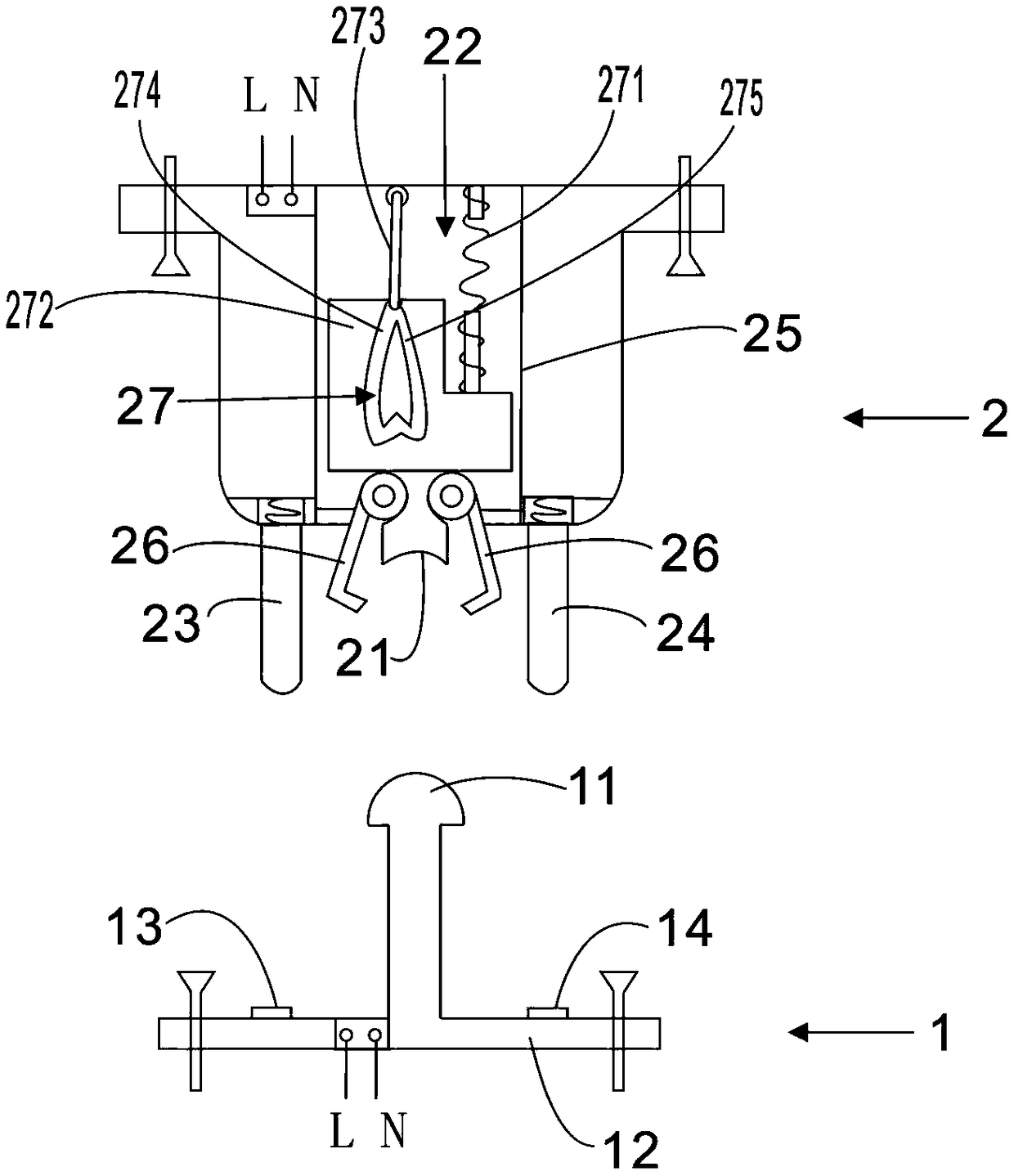

[0020] see figure 1 and figure 2 As shown, a self-locking power connector includes a fastener 1 and a clip 2 .

[0021] Among them, the fastener 1 is provided with a ball stud 11 and a contact plate 12 fixedly connected with the ball stud 11, and the touch plate 12 is provided with an N-level electrical contact piece 13 and an L-level electrical contact piece 14; The electric contact piece 13 and the L-level electric contact piece 14 are respectively located at both ends of the contact plate 12; the ball head part of the ball head protrusion can preferably be a hemispherical head.

[0022] The clip 2 is provided with an arc-shaped groove 21 for supporting the ball stud 11, and the both sides of the arc-shaped groove 21 are provided with movable clip devices 22; the two sides of the movable clip device are provided with N-level electric contacts 23 and L N-level electrical contact pin 24; N-level electrical contact pin 23 and L-level electrical contact pin 24 can be preferab...

Embodiment 3

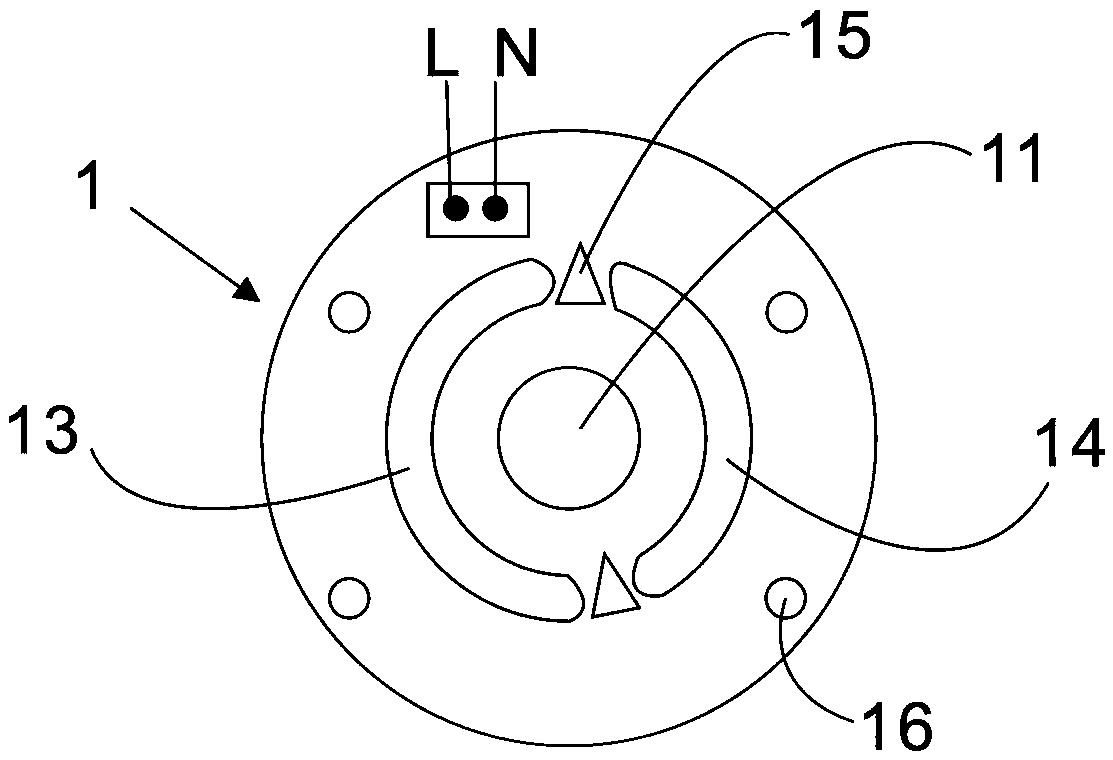

[0032] As another specific implementation, see image 3 As shown, the N-level electrical contact piece 13 and the L-level electrical contact piece 14 in this embodiment are surrounded by an arc, and a three-dimensional triangular plastic spacer 15 is provided between the N-level electrical contact piece 13 and the L-level electrical contact piece 14 . In this way, combined with the ball stud 11 (the ball head can be rotated arbitrarily), the fastener 1 can be fastened with the fastener 2 at almost any angle of 360 degrees. Wherein the effect of the three-dimensional triangular plastic spacer 15 is that the N-level electric contact pin and the L-level electric contact pin will naturally not be buckled when pushed against the three-dimensional triangular plastic spacer, which increases safety. At this time, the ball stud can be buckled up and contacted with the N-level electric contact piece and the L-level electric contact piece to turn on the power supply by slightly adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com