Novel drawing and hanging mechanism for tractor and tractor with mechanism

A tractor and main body technology, applied in the field of tractors, can solve the problems of high work intensity, increase the difficulty of operation, narrow operating space, etc., and achieve the effect of convenient height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

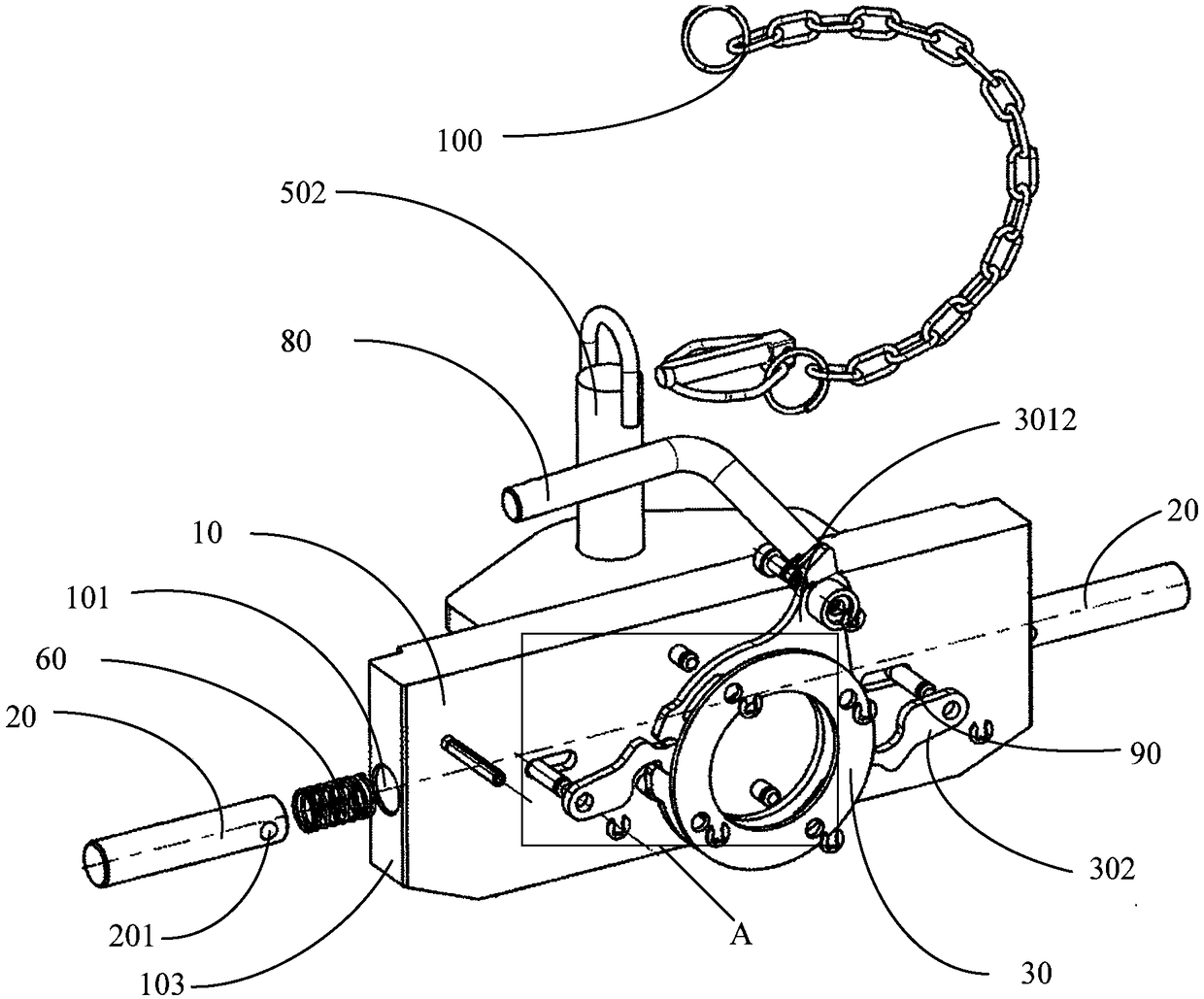

[0082] A specific embodiment of the present invention provides a towing mechanism, which mainly includes a bracket 40 , a connecting body 10 matched with the bracket 40 , and a towing connector 50 fixed on the connecting body 10 .

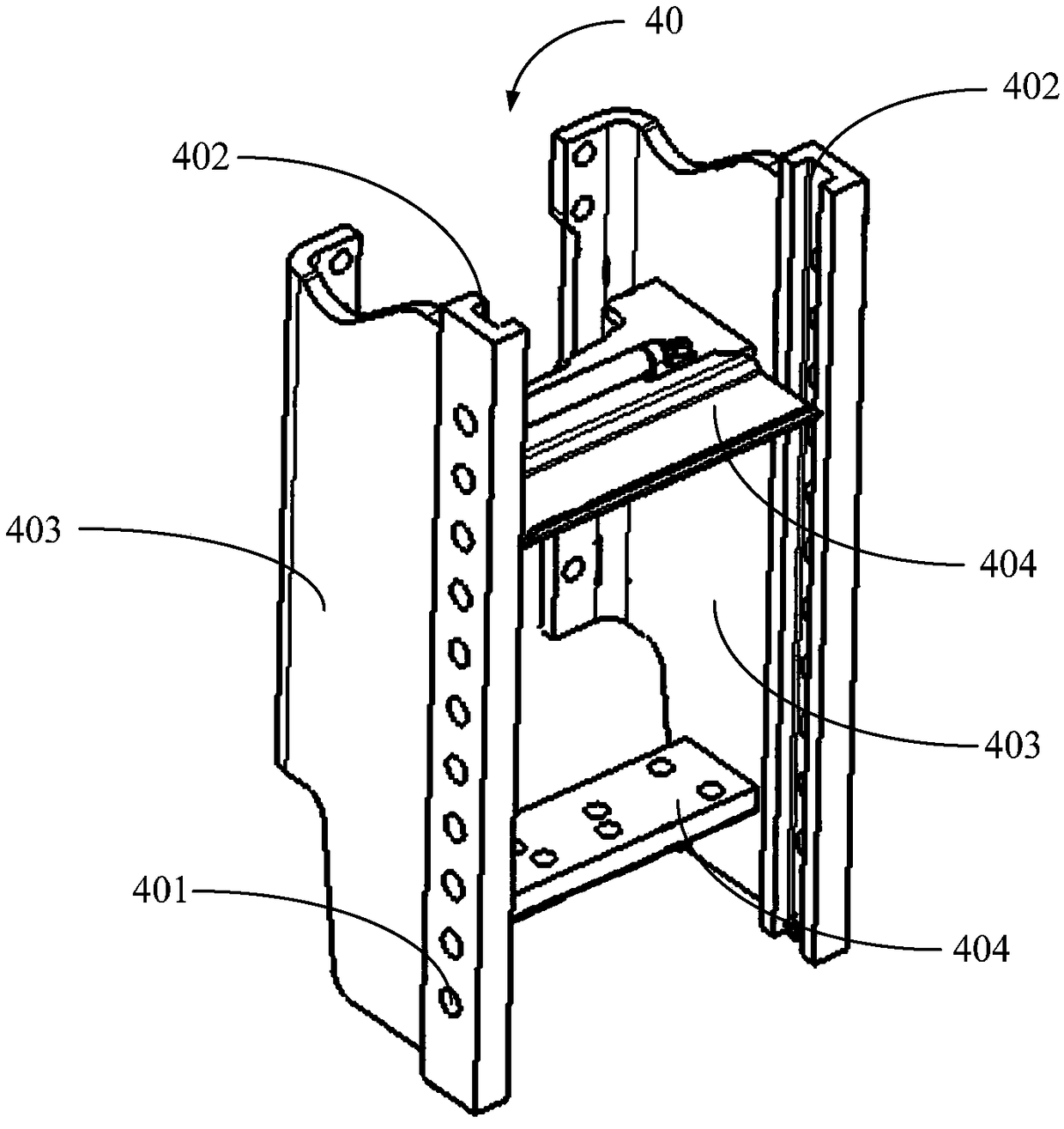

[0083] Wherein, the bracket 40 includes two side plates 403 arranged oppositely, two horizontal plates 404 arranged up and down connecting the two side plates 403 (for example, by welding), and two slide grooves 402 are respectively welded on the two side plates 403 (In this embodiment, the chute 402 specifically refers to a plate body with a groove, that is, the plate body is approximately U-shaped). The bottom of the chute 402 is provided with a plurality of limiting holes 401 arranged up and down.

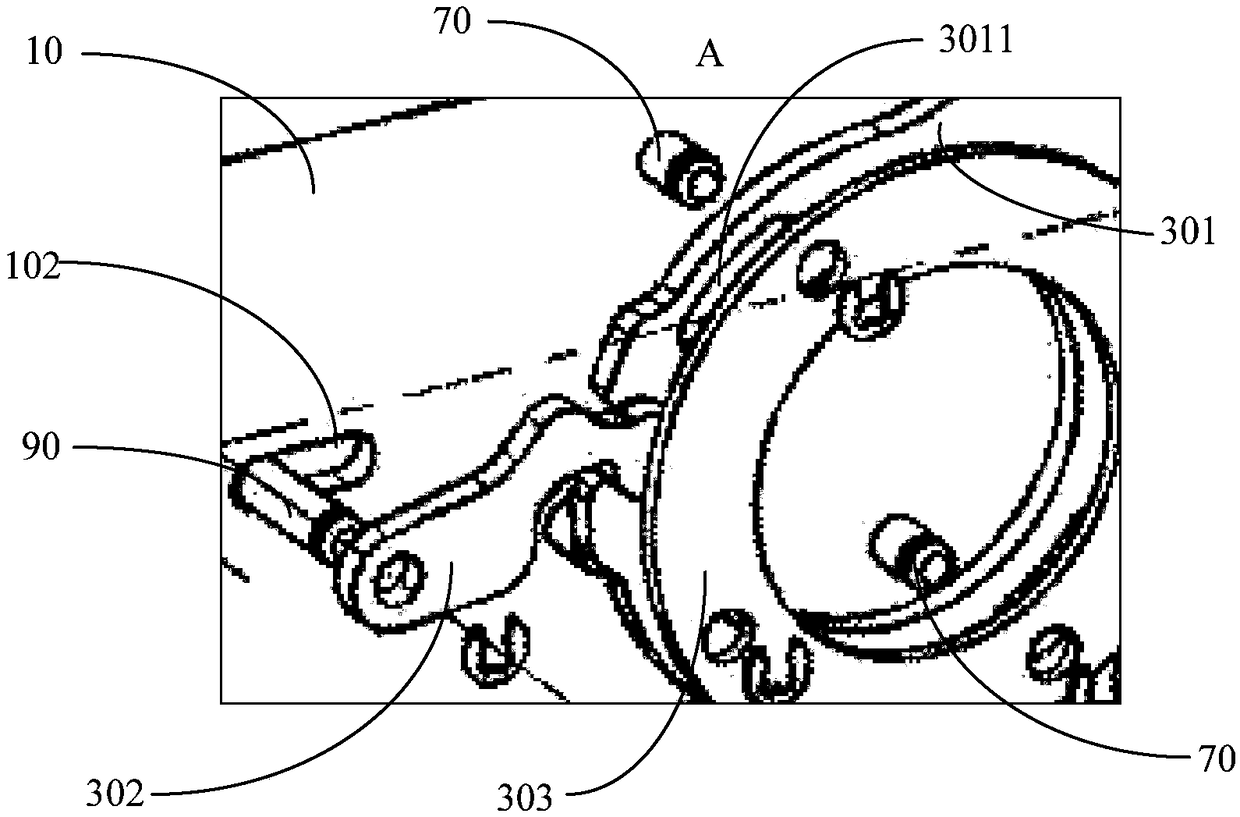

[0084] The connecting body 10 is provided with a lock hole 101, the lock tongue 20 is sleeved in the lock hole 101 and an elastic member 60 (such as a spring) is arranged between the lock tongue 20 and the connecting body 10, and the lock tongue 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com